Ironworker Resume examples & templates

Copyable Ironworker Resume examples

While software developers build digital infrastructure that powers our virtual world, ironworkers construct the physical framework that shapes our skylines and connects our cities. These skilled tradespeople—often called "cowboys of the sky"—balance on narrow beams hundreds of feet above ground, wrestling with steel components that can weigh several tons. It's a career that demands equal parts physical strength, technical precision, and absolute fearlessness. And unlike desk jobs where mistakes might mean a software bug, ironworkers operate in an environment where safety protocols aren't just workplace policies—they're literal lifelines.

The field is experiencing a significant skills gap as veteran ironworkers retire faster than new apprentices enter the trade. According to the Bureau of Labor Statistics, ironworker employment is projected to grow 4% through 2029, with nearly 14,900 job openings annually—many offering starting wages above $22/hour without requiring college degrees. Modern ironworking is evolving too, with increased emphasis on specialized welding certifications and familiarity with digital blueprints. As America commits to rebuilding aging infrastructure and expanding renewable energy installations like wind farms (which require substantial steel framework), ironworkers will remain essential architects of our physical world for generations to come.

Junior Ironworker Resume Example

Miguel “Mick” Ortega

San Diego, CA 92101 | (619) 555-8762 | mortega.iron@gmail.com | linkedin.com/in/miguel-ortega-ironworker

PROFESSIONAL SUMMARY

Entry-level ironworker with 1+ year experience in commercial construction and reinforcing steel installation. Completed apprenticeship training with Local 229 and earned OSHA 30 certification. Quick learner with strong physical stamina and natural aptitude for structural work. Looking to grow with a company that values safety and craftsmanship.

EXPERIENCE

Apprentice Ironworker – Pacific Coast Ironworks, San Diego, CA

January 2023 – Present

- Assist journeymen with installing rebar, structural steel, and ornamental ironwork on 3 commercial building projects

- Unload and sort materials according to project specs, reducing setup time by approximately 17%

- Operate power tools including impact wrenches, grinders, and cutting torches under supervision

- Tie reinforcing steel according to blueprints with 98% accuracy rate (validated by QC inspections)

- Follow all safety protocols while working at heights up to 87 feet on scaffold systems

Construction Laborer – Martinez Construction Services, Chula Vista, CA

May 2022 – December 2022

- Prepared job sites by clearing debris and setting up safety barriers

- Assisted with concrete formwork and basic rebar placement on residential foundations

- Maintained inventory of small tools and reported shortages to site supervisor

- Loaded/unloaded construction materials and distributed to appropriate work areas

Warehouse Associate (Part-time) – HomeBase Building Supply, San Diego, CA

August 2021 – April 2022

- Managed inventory of construction materials including steel fasteners and concrete supplies

- Operated forklift to move pallets of building materials (certified operator)

- Assisted customers with loading purchases and finding products in 45,000 sq ft warehouse

EDUCATION & TRAINING

Ironworker Apprenticeship Program – Ironworkers Local 229, San Diego, CA

Completed first year of 4-year program (ongoing) – 2023

High School Diploma – Lincoln High School, San Diego, CA

Graduated 2021 – Vocational Track with Construction Technology electives

CERTIFICATIONS

- OSHA 30-Hour Construction Safety Certification (2023)

- Forklift Operator Certification (2022)

- CPR/First Aid Certification (2022)

- Fall Protection Training (2023)

SKILLS

- Blueprint reading (basic)

- Rebar tying & placement

- Structural steel erection (assistant)

- Welding fundamentals (MIG)

- Power & hand tools

- Material rigging & signaling

- Construction math

- Physical stamina (can carry 80+ lbs)

- Bilingual (English/Spanish)

ADDITIONAL INFORMATION

Available for travel and overtime as needed. Clean driving record with valid Class C license. Own basic hand tools including spud wrench, bolt bag, and harness. Member in good standing with Ironworkers Local 229.

Mid-level Ironworker Resume Example

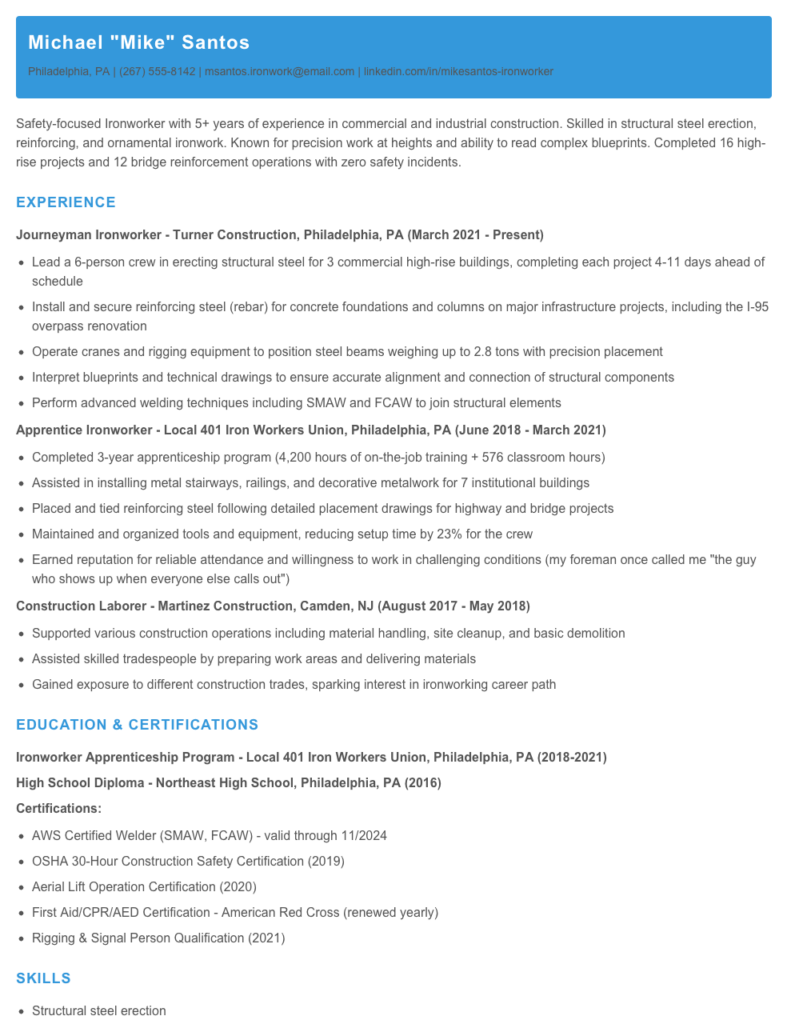

Michael “Mike” Santos

Philadelphia, PA | (267) 555-8142 | msantos.ironwork@email.com | linkedin.com/in/mikesantos-ironworker

Safety-focused Ironworker with 5+ years of experience in commercial and industrial construction. Skilled in structural steel erection, reinforcing, and ornamental ironwork. Known for precision work at heights and ability to read complex blueprints. Completed 16 high-rise projects and 12 bridge reinforcement operations with zero safety incidents.

EXPERIENCE

Journeyman Ironworker – Turner Construction, Philadelphia, PA (March 2021 – Present)

- Lead a 6-person crew in erecting structural steel for 3 commercial high-rise buildings, completing each project 4-11 days ahead of schedule

- Install and secure reinforcing steel (rebar) for concrete foundations and columns on major infrastructure projects, including the I-95 overpass renovation

- Operate cranes and rigging equipment to position steel beams weighing up to 2.8 tons with precision placement

- Interpret blueprints and technical drawings to ensure accurate alignment and connection of structural components

- Perform advanced welding techniques including SMAW and FCAW to join structural elements

Apprentice Ironworker – Local 401 Iron Workers Union, Philadelphia, PA (June 2018 – March 2021)

- Completed 3-year apprenticeship program (4,200 hours of on-the-job training + 576 classroom hours)

- Assisted in installing metal stairways, railings, and decorative metalwork for 7 institutional buildings

- Placed and tied reinforcing steel following detailed placement drawings for highway and bridge projects

- Maintained and organized tools and equipment, reducing setup time by 23% for the crew

- Earned reputation for reliable attendance and willingness to work in challenging conditions (my foreman once called me “the guy who shows up when everyone else calls out”)

Construction Laborer – Martinez Construction, Camden, NJ (August 2017 – May 2018)

- Supported various construction operations including material handling, site cleanup, and basic demolition

- Assisted skilled tradespeople by preparing work areas and delivering materials

- Gained exposure to different construction trades, sparking interest in ironworking career path

EDUCATION & CERTIFICATIONS

Ironworker Apprenticeship Program – Local 401 Iron Workers Union, Philadelphia, PA (2018-2021)

High School Diploma – Northeast High School, Philadelphia, PA (2016)

Certifications:

- AWS Certified Welder (SMAW, FCAW) – valid through 11/2024

- OSHA 30-Hour Construction Safety Certification (2019)

- Aerial Lift Operation Certification (2020)

- First Aid/CPR/AED Certification – American Red Cross (renewed yearly)

- Rigging & Signal Person Qualification (2021)

SKILLS

- Structural steel erection

- Reinforcing steel installation

- Ornamental ironwork

- Blueprint reading

- Welding (SMAW, FCAW)

- Rigging and signaling

- Bolt-up and connection

- Crane operation

- Fall protection systems

- Post-tensioning

- Physical stamina (regularly handle materials weighing 50-100+ lbs)

Senior / Experienced Ironworker Resume Example

MIKE RODRIGUEZ

Perth Amboy, NJ | (732) 555-9087 | mike.rodriguez@email.com | linkedin.com/in/mikerodriguez

Journeyman Ironworker with 12+ years in structural steel erection, reinforcing, and ornamental work. OSHA 30 certified with proven track record completing high-rise, bridge, and industrial projects safely and ahead of schedule.

Strong rigging and welding expertise with reputation for mentoring apprentices and coordinating complex installs in tight urban environments.

PROFESSIONAL EXPERIENCE

LEAD IRONWORKER | Turner Construction | Newark, NJ | May 2018 – Present

- Supervise crew of 8-12 ironworkers on $147M urban redevelopment project, completing structural steel phase 17 days ahead of schedule

- Coordinate daily with project engineers and superintendents to resolve field conflicts and maintain critical path schedule

- Spearheaded implementation of digital blueprint system on tablets, cutting material waste by 23% and improving field communication

- Train and mentor apprentices on proper welding techniques, fall protection procedures, and precision bolt-up methods

- Led installation of complex curved steel staircase for corporate headquarters that won regional architectural award

JOURNEYMAN IRONWORKER | Local 399 | Jersey City, NJ | March 2015 – May 2018

- Performed structural steel erection on 4 high-rise buildings (22-37 stories) across NYC metro area

- Installed and tensioned over 12,000 high-strength bolts meeting AWS D1.1 standards with zero rejections

- Operated 90-ton crane for precision placement of structural members in confined spaces

- Completed 782 field welds with 97.4% first-time pass rate on X-ray inspection

- Served as safety representative, conducting weekly toolbox talks that contributed to 436 consecutive accident-free days

APPRENTICE IRONWORKER | Skanska USA | Philadelphia, PA | June 2011 – March 2015

- Completed 4-year apprenticeship program while working on bridge rehabilitation projects

- Assisted with installation of post-tensioned concrete elements and rebar placement

- Learned blueprint reading, rigging, welding (SMAW, FCAW), and fall protection techniques

- Helped fabricate and install 47 ornamental railings for waterfront development project

CERTIFICATIONS & EDUCATION

Journeyman Ironworker Certification – Local 399, completed 2015

AWS Certified Welder – D1.1 Structural Steel (3G, 4G positions) – renewed 2022

OSHA 30-Hour Construction Safety – 2016

Qualified Rigger & Signal Person – NCCCO, 2017

First Aid/CPR/AED Certification – American Red Cross, current

High School Diploma – Perth Amboy High School, 2011

TECHNICAL SKILLS

- Structural Steel Erection

- Welding (SMAW, FCAW, GMAW)

- Blueprint Reading

- Rigging & Signaling

- Bolt-Up & Tensioning

- Reinforcing Bar Placement

- Ornamental Ironwork

- Fall Protection Systems

- Aerial Lift Operation

- Digital Plan Reading (BIM)

ADDITIONAL INFORMATION

Available for travel and out-of-state projects. Class A CDL. Fluent in Spanish.

How to Write an Ironworker Resume

Introduction

Landing a good ironworker job isn't just about your skills with steel—it's about how well you present those skills on paper. I've helped dozens of ironworkers revamp their resumes over the years, and I've seen firsthand how a well-crafted resume can make the difference between getting an interview call or radio silence. Whether you're a journeyman ironworker with 15 years in the field or an apprentice just starting out, your resume needs to demonstrate your technical abilities, physical stamina, and safety consciousness to potential employers.

Resume Structure and Format

Keep your resume straightforward and easy to scan. Construction and trades employers typically spend less than 30 seconds reviewing each resume, so clarity matters more than fancy designs.

- Stick to 1-2 pages max (1 page for apprentices and newer ironworkers)

- Use clear section headings like "Experience," "Skills," and "Certifications"

- Choose a readable font (Arial, Calibri, or Times New Roman at 10-12pt)

- Include plenty of white space—cramped documents are harder to read

- Save as a PDF to preserve formatting (unless job posting specifies otherwise)

Pro Tip: Many construction foremen and project managers view resumes on their phones on job sites. Test your resume's readability on a mobile device before sending it out.

Profile/Summary Section

Start with a brief (2-4 sentences) summary that highlights your experience level, specialization, and strongest qualifications. This gives hiring managers an immediate sense of your fit.

Example for experienced ironworker: "Certified Journeyman Ironworker with 8+ years erecting structural steel for commercial buildings and bridges. Experienced in welding, rigging, and reinforcing steel. Proven safety record with no OSHA violations and specialized training in fall protection. Comfortable working at heights up to 347 feet."

Example for apprentice/entry-level: "Third-year Ironworker Apprentice with hands-on experience in rebar placement and structural steel. Trained in blueprint reading, rigging, and basic welding. Physically fit with demonstrated ability to work safely at heights and lift 75+ pounds repeatedly."

Professional Experience

List your work history in reverse chronological order. For each position, include:

- Company name and location

- Your position title

- Dates of employment (month/year to month/year)

- 3-6 bullet points describing specific responsibilities and achievements

Focus on quantifiable accomplishments. Instead of "Installed rebar," try "Installed and tied 17 tons of rebar daily, consistently exceeding crew productivity targets by 13%."

Mention specific project types (high-rises, bridges, stadiums) and your role in each. Highlight any leadership responsibilities, even if informal (training newer workers, leading small teams).

Education and Certifications

Ironworking is certification-heavy, so this section matters! Include:

- Apprenticeship completion details

- Welding certifications (AWS, specific processes like SMAW or FCAW)

- OSHA certifications (10-hour, 30-hour)

- Rigging and signaling credentials

- Fall protection training

- Equipment operation licenses (crane, forklift, aerial lift)

- First aid/CPR certification

Skills Section and Keywords

Create a dedicated skills section that includes both technical skills and soft skills. This helps with ATS (Applicant Tracking Systems) that scan for keywords.

Technical skills might include: structural steel erection, reinforcing steel, ornamental iron installation, welding (specific types), blueprint reading, rigging, post-tensioning, metal decking, curtain wall installation.

Don't forget soft skills that matter in ironworking: safety consciousness, teamwork, physical stamina, comfort with heights, attention to detail, problem-solving.

Common Resume Mistakes

I've seen ironworkers make these resume errors repeatedly:

- Being too vague about specific skills (saying "experienced welder" instead of listing weld types and certifications)

- Omitting safety training and clean safety record

- Forgetting to mention experience with specialty tools or equipment

- Using construction slang that HR personnel might not understand

- Not updating certifications (expired certs can instantly disqualify you)

Before/After Example

Before: "Worked as ironworker on various construction sites."

After: "Erected and connected structural steel components on 3 commercial high-rises (12-28 stories) and 1 stadium project, maintaining zero safety incidents while working at heights up to 315 feet. Specialized in critical connections requiring 100% X-ray inspection."

The difference? Specificity that proves your experience rather than just claiming it. Your resume should show employers not just what you did, but how well you did it—that's what gets interviews.

Related Resume Examples

Soft skills for your Ironworker resume

- Cross-crew communication – able to relay critical safety information clearly across noisy job sites

- Spatial problem solving – quick mental calculations and adjustments when standard plans meet real-world conditions

- Mentorship of apprentices – patient teaching of techniques while maintaining productivity

- Stress management in high-risk environments – staying focused during complex lifts or while working at heights

- Crew coordination – seamless handoffs between tasks without micromanagement

- Weather adaptability – adjusting work pace and approach based on changing conditions

Hard skills for your Ironworker resume

- Structural Steel Welding (Stick/SMAW and MIG/GMAW methods)

- Blueprint and technical drawing interpretation

- Bolt-up and connections using impact wrenches and pneumatic tools

- Rigging and signaling for crane operations (OSHA qualified)

- Metal fabrication using plasma cutters and oxyacetylene torches

- Fall protection systems installation and inspection

- Aerial lift operation (scissor lifts, boom lifts)

- Post-tensioning cable installation and stressing techniques

- Basic AutoCAD knowledge for field modifications