Welder Resume examples & templates

Copyable Welder Resume examples

The welding industry is experiencing a revival in the US manufacturing sector, with specialized positions in robotic welding integration growing by 17.3% since 2020. Traditional welding skills remain in high demand, but the field is evolving rapidly as manufacturers adopt automation alongside manual techniques. This dual approach isn't replacing welders—it's transforming their role into something more technical. Many shops now seek "hybrid welders" who can both perform manual welds and program or troubleshoot automated systems.

For skilled welders, this shift creates fantastic opportunities. The skills gap in manufacturing means companies are struggling to find qualified personnel who understand both the art and science of joining metals. And it's not just heavy industry anymore; aerospace, automotive, and even medical device manufacturers need specialized welding expertise. With infrastructure projects ramping up across the country and reshoring efforts bringing production back to American soil, welders with the right certifications and adaptability will find themselves in an enviable position for years to come.

Junior Welder Resume Example

MARCO RODRIGUEZ

Denver, CO 80219 • (720) 555-8762 • m.rodriguez@emailpro.net • linkedin.com/in/marco-rodriguez

Entry-level welder with 1+ year of hands-on experience in MIG and TIG welding processes. OSHA-certified with proven ability to interpret blueprints and technical drawings. Quick learner who thrives in fast-paced environments and consistently maintains quality standards. Looking to grow my welding career with an established fabrication company.

EXPERIENCE

Junior Welder – Precision Metal Works, Denver, CO (June 2023 – Present)

- Perform MIG and TIG welding on carbon steel, aluminum, and stainless steel components for commercial HVAC systems

- Read and interpret blueprints to ensure accurate assembly of metal components with tolerances of ±1/16″

- Complete approximately 15-20 welding projects per week while maintaining 94% first-pass quality rate

- Assist in troubleshooting equipment malfunctions, reducing downtime by 17% in Q1 2024

Welding Apprentice – Colorado Construction Services, Aurora, CO (August 2022 – May 2023)

- Supported journeyman welders with material preparation, workstation setup, and cleanup

- Gained hands-on experience with MIG welding techniques while working on structural steel components

- Helped maintain welding equipment through daily inspections and routine maintenance

- Practiced blueprint reading and weld symbol interpretation under supervision

Warehouse Associate – MetalSupply Inc., Lakewood, CO (March 2022 – July 2022)

- Processed incoming and outgoing steel shipments in a high-volume distribution center

- Operated forklifts and other material handling equipment to move metal stock

- Maintained accurate inventory records and assisted with monthly cycle counts

EDUCATION & CERTIFICATIONS

Certificate in Welding Technology – Colorado Technical Institute, Denver, CO (2022)

- Completed 720 hours of classroom and hands-on welding instruction

- Specialized training in MIG, TIG, and stick welding processes

Certifications:

- AWS D1.1 Structural Welding Certification (2023)

- OSHA 10-Hour General Industry Safety (2022)

- Forklift Operator Certification (2022)

SKILLS

- Welding Processes: MIG (GMAW), TIG (GTAW), Stick (SMAW)

- Materials: Carbon Steel, Stainless Steel, Aluminum

- Blueprint Reading & Weld Symbol Interpretation

- Quality Control & Inspection

- Basic Metallurgy Knowledge

- Power & Hand Tools Operation

- Equipment Maintenance

- Safety Protocols & PPE

- Material Handling

- Basic Mathematics & Measurements

Mid-level Welder Resume Example

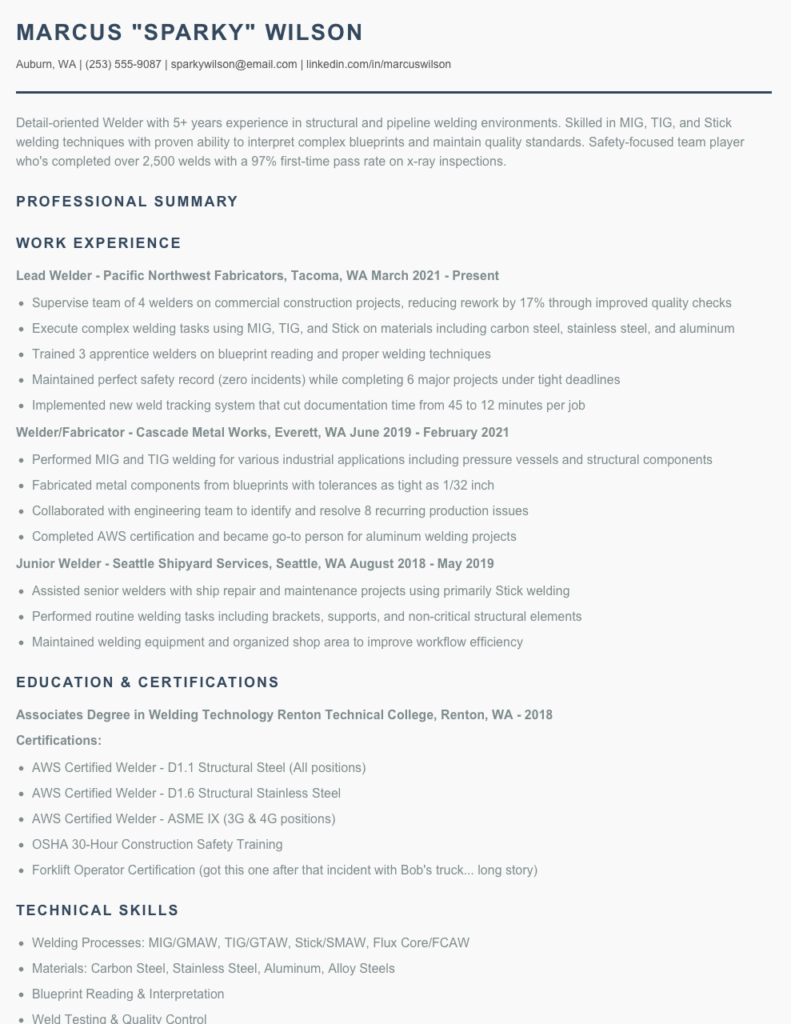

Marcus “Sparky” Wilson

Auburn, WA | (253) 555-9087 | sparkywilson@email.com | linkedin.com/in/marcuswilson

PROFESSIONAL SUMMARY

Detail-oriented Welder with 5+ years experience in structural and pipeline welding environments. Skilled in MIG, TIG, and Stick welding techniques with proven ability to interpret complex blueprints and maintain quality standards. Safety-focused team player who’s completed over 2,500 welds with a 97% first-time pass rate on x-ray inspections.

WORK EXPERIENCE

Lead Welder – Pacific Northwest Fabricators, Tacoma, WA

March 2021 – Present

- Supervise team of 4 welders on commercial construction projects, reducing rework by 17% through improved quality checks

- Execute complex welding tasks using MIG, TIG, and Stick on materials including carbon steel, stainless steel, and aluminum

- Trained 3 apprentice welders on blueprint reading and proper welding techniques

- Maintained perfect safety record (zero incidents) while completing 6 major projects under tight deadlines

- Implemented new weld tracking system that cut documentation time from 45 to 12 minutes per job

Welder/Fabricator – Cascade Metal Works, Everett, WA

June 2019 – February 2021

- Performed MIG and TIG welding for various industrial applications including pressure vessels and structural components

- Fabricated metal components from blueprints with tolerances as tight as 1/32 inch

- Collaborated with engineering team to identify and resolve 8 recurring production issues

- Completed AWS certification and became go-to person for aluminum welding projects

Junior Welder – Seattle Shipyard Services, Seattle, WA

August 2018 – May 2019

- Assisted senior welders with ship repair and maintenance projects using primarily Stick welding

- Performed routine welding tasks including brackets, supports, and non-critical structural elements

- Maintained welding equipment and organized shop area to improve workflow efficiency

EDUCATION & CERTIFICATIONS

Associates Degree in Welding Technology

Renton Technical College, Renton, WA – 2018

Certifications:

- AWS Certified Welder – D1.1 Structural Steel (All positions)

- AWS Certified Welder – D1.6 Structural Stainless Steel

- AWS Certified Welder – ASME IX (3G & 4G positions)

- OSHA 30-Hour Construction Safety Training

- Forklift Operator Certification (got this one after that incident with Bob’s truck… long story)

TECHNICAL SKILLS

- Welding Processes: MIG/GMAW, TIG/GTAW, Stick/SMAW, Flux Core/FCAW

- Materials: Carbon Steel, Stainless Steel, Aluminum, Alloy Steels

- Blueprint Reading & Interpretation

- Weld Testing & Quality Control

- Metal Fabrication & Layout

- Precision Measuring Tools

- Grinding & Finishing Techniques

- Basic AutoCAD

- Shop Math & Calculations

ADDITIONAL INFORMATION

Available for travel and emergency repair projects. Own complete set of personal PPE and basic tools. Sometimes bring my famous jalapeno cornbread to Friday team lunches.

Senior / Experienced Welder Resume Example

Miguel “Mike” Ramirez

Denver, CO 80219 • (720) 555-8176 • mike.ramirez84@gmail.com • linkedin.com/in/mikeramirez-welder

Certified Welder with 10+ years of progressive experience specializing in MIG, TIG, and Stick welding techniques. Proven track record maintaining quality standards while meeting tight production deadlines. Experienced in blueprint reading, fabrication, and ensuring compliance with safety protocols. Skilled mentor who has trained 14+ junior welders throughout career.

PROFESSIONAL EXPERIENCE

Senior Welder | Rocky Mountain Fabrication | Denver, CO | 03/2018 – Present

- Lead welding operations for critical aerospace and defense components, maintaining a 99.3% first-pass quality rate on precision parts

- Manage and coordinate a team of 5 welders on complex structural projects, reducing completion time by 22% through improved workflow organization

- Interpret and execute advanced blueprints and engineering specifications for custom fabrication projects worth $250K-$750K

- Implemented preventative maintenance schedule for 12 welding machines, cutting repair costs by $17,400 annually

- Collaborate with engineering team to develop welding procedures for specialty metals including Inconel and titanium alloys

Welder Fabricator | Precision Metal Works | Lakewood, CO | 06/2015 – 03/2018

- Performed MIG, TIG, and Stick welding on various materials including carbon steel, stainless steel, and aluminum

- Fabricated custom metal structures and components based on client specifications and engineering drawings

- Operated overhead cranes, forklifts, and plasma cutters to prepare materials for welding processes

- Cross-trained 4 entry-level welders on blueprint reading and quality control procedures

- Recognized for completing a rush order for mining equipment components 3 days ahead of schedule

Welder | Mountainside Construction | Colorado Springs, CO | 08/2013 – 05/2015

- Performed structural welding for commercial building projects using primarily Stick and MIG techniques

- Conducted field repairs on construction equipment, often in challenging weather conditions

- Maintained detailed logs of welding activities and material usage for project documentation

- Assisted in developing a streamlined inventory system that reduced material waste by 17%

CERTIFICATIONS

- AWS D1.1 Structural Welding Certification (renewed 2022)

- AWS D1.5 Bridge Welding Certification (2020)

- ASME Section IX Pressure Vessel Certification (2019)

- OSHA 30-Hour Construction Safety Certification (2017)

- Forklift Operator Certification (renewed 2021)

EDUCATION

Associate of Applied Science, Welding Technology

Front Range Community College | Westminster, CO | 2013

TECHNICAL SKILLS

- Welding Processes: MIG, TIG, Stick, Flux Core

- Materials: Carbon Steel, Stainless Steel, Aluminum, Inconel, Titanium

- Equipment: Miller, Lincoln, ESAB welding machines

- Fabrication: Plasma cutting, metal forming, grinding

- Blueprint Reading & Shop Math

- Quality Control & Inspection

- Preventative Maintenance

- Safety Protocols & PPE

- Basic CAD software (Solidworks)

ADDITIONAL INFORMATION

Volunteer instructor at Denver Youth Trades Program teaching basic welding skills to at-risk teens (2019-present)

Spanish: Conversational proficiency

How to Write a Welder Resume

Introduction

Your welder resume isn't just a list of places you've worked—it's your ticket to that next gig or career move. I've seen thousands of welder resumes over my 15 years as a career coach, and let me tell you: the difference between getting an interview and getting ignored often comes down to how effectively you showcase your skills and experience. Whether you're a fresh-faced welding school grad or a seasoned pipe welder with 20+ years in the field, a strong resume speaks volumes about your attention to detail (something critical in welding!).

Resume Structure and Format

Keep your welder resume clean and organized—just like your work area should be. One page is perfect for most welders with under 10 years of experience; two pages max for veterans with extensive project history.

- Stick with easy-to-read fonts like Arial, Calibri, or Times New Roman at 11-12pt

- Use bold headers to separate sections (Experience, Skills, Certifications)

- Include plenty of white space—crowded resumes are hard to scan

- Save as PDF unless specifically asked for a different format

- Name your file professionally (JohnSmith_Welder_Resume.pdf)

Profile/Summary Section

Your summary should be 3-4 lines that pack a punch. Mention your welding specialties, years of experience, and standout achievements. This isn't where you say you're "looking for an opportunity"—it's where you tell them what you bring to the table.

Example: "AWS-certified combination welder with 7+ years specializing in TIG and MIG processes. Experienced in structural and pipe welding for oil & gas projects with 99.3% pass rate on x-ray tests. Skilled in blueprint reading and safely operating in confined spaces."

Pro tip: Tailor your summary to match each job. If they need someone with aluminum welding experience and you have it, make sure that's mentioned up front!

Professional Experience

This is the meat of your resume. For each position, include:

- Company name, location, and dates (month/year)

- Job title (be specific: "Structural Welder" rather than just "Welder")

- 3-5 bullet points highlighting specific responsibilities and achievements

- Measurable results when possible (completed 47 pipe welds per shift, maintained 98% first-pass inspection rate)

Start each bullet with action verbs: Fabricated, Welded, Interpreted, Maintained, Repaired. Avoid "Responsible for..." statements—they're boring and don't show what you actually accomplished.

Education and Certifications

Certifications often matter more than formal education for welders. List your most relevant and current certs first:

- AWS certifications (specific to processes you're certified in)

- ASME Section IX qualifications

- State/local welding licenses

- Safety certifications (OSHA 10/30, confined space, fall protection)

- Technical school training or apprenticeship details

Keywords and ATS Tips

Many companies use Applicant Tracking Systems that scan for specific terms. Include keywords from the job posting such as welding processes

(SMAW, GMAW, GTAW, FCAW), materials (steel, aluminum, stainless), positions (1G, 2F, 6G), and specific equipment you've used. Don't just list abbreviations—spell them out at least once (Gas Metal Arc Welding/GMAW).

Industry-specific Terms

Sprinkle these throughout your resume to show you know your stuff:

- Specific welding codes and standards you've worked with (AWS D1.1, ASME Section IX)

- Inspection methods (visual, x-ray, dye penetrant, ultrasonic)

- Joint types and positions you're experienced with

- Specialized equipment (brand names can help)

- Material thicknesses you typically work with

Common Mistakes to Avoid

- Lying about certifications (they WILL check)

- Using generic descriptions that could apply to any welder

- Focusing on basic duties instead of achievements

- Omitting specific welding processes you're skilled in

- Including outdated certifications without noting they've expired

Before/After Example

Before: "Responsible for welding parts together."

After: "Performed GTAW welding on 304 stainless steel pressure vessels, maintaining 97% first-pass x-ray acceptance rate while completing an average of 12 critical joints per shift."

Your resume should showcase not just what you did, but how well you did it. In a field where precision matters down to the millimeter, make sure your resume reflects that same attention to detail!

Related Resume Examples

Soft skills for your Welder resume

- Safety advocacy – willing to speak up when procedures aren’t being followed and mentor newer team members on proper precautions

- Blueprint interpretation and spatial reasoning that helps communicate complex fabrication needs to project managers

- Team coordination during multi-person projects, especially in confined spaces or when handling heavy materials

- Troubleshooting under pressure – staying calm when welds fail inspection or when unexpected material issues arise

- Attention to detail balanced with practical efficiency to meet both quality standards and production timelines

- Adaptability to different work environments from shop floors to outdoor construction sites to underwater repairs

Hard skills for your Welder resume

- AWS D1.1 Structural Welding Certification

- MIG/TIG/Stick Welding (6G position competency)

- Blueprint reading and welding symbol interpretation

- Flux-cored arc welding (FCAW) for industrial applications

- Pipe fitting and fabrication (Schedule 40/80)

- Experience with 3/8″ to 2″ plate thickness welding

- Weld inspection and quality testing procedures

- CNC plasma cutting programming basics

- Miller and Lincoln equipment maintenance