Manufacturing Planner Resume examples & templates

Copyable Manufacturing Planner Resume examples

Manufacturing Planners are the unseen architects behind every product that reaches your hands. While engineers design and operators build, planners create the invisible framework that transforms raw materials into finished goods with remarkable precision. They're the chess players of production, thinking five moves ahead to prevent bottlenecks before they happen. In a manufacturing landscape where just-in-time delivery has shrunk inventory buffers to mere hours, a skilled planner can mean the difference between profit and disaster.

The field is undergoing a quiet revolution as Industry 4.0 technologies redefine what's possible. A recent McKinsey study found that manufacturers implementing advanced planning systems reduced production lead times by 17.3% on average—not an insignificant number when competitors are fighting for every percentage point of efficiency. The modern Manufacturing Planner isn't just scheduling production; they're interpreting terabytes of data from connected machines, balancing competing priorities from sales and operations, and finding creative solutions when suppliers halfway around the world face unexpected disruptions. As manufacturing continues its digital transformation, planners who can bridge the gap between traditional production knowledge and emerging technologies will shape the factories of tomorrow.

Junior Manufacturing Planner Resume Example

Trevor Mitchell

Denver, CO • (720) 555-8904 • trevor.mitchell@email.com • linkedin.com/in/trevormitchell

Professional Summary

Recent engineering graduate with 1+ year of manufacturing planning experience. Skilled in MRP systems, inventory management, and production scheduling. Looking to leverage my analytical capabilities and technical knowledge to improve operational efficiency at a growing manufacturing company.

Experience

Junior Manufacturing Planner – Precision Components Inc., Denver, CO

March 2023 – Present

- Coordinate with production supervisors to develop weekly schedules for 3 assembly lines, reducing idle time by 14%

- Manage inventory levels for 278 SKUs, implementing a new min/max system that decreased stockouts by 31%

- Create and maintain bills of materials (BOMs) in SAP, ensuring 99.7% accuracy in component requirements

- Support MRP runs and analyze results to identify potential material shortages before they impact production

- Participate in daily production meetings to address scheduling conflicts and resource allocation challenges

Manufacturing Intern – Westfield Manufacturing Solutions, Boulder, CO

May 2022 – August 2022

- Assisted planning team with data collection and analysis to support capacity planning initiatives

- Helped develop Excel templates for tracking production KPIs, saving planners approximately 5 hours weekly

- Shadowed senior planners during S&OP meetings to understand cross-functional planning processes

- Conducted time studies on 6 assembly operations to help establish more accurate standard times

Supply Chain Assistant (Part-time) – University Machine Shop, Colorado State University

September 2021 – May 2022

- Managed inventory of materials and tools for student engineering projects

- Processed material requests and coordinated with vendors for special orders

- Created a digital tracking system that reduced material waste by 23%

Education

Bachelor of Science in Industrial Engineering – Colorado State University

Graduated: May 2022

Relevant Coursework: Production Planning, Operations Research, Supply Chain Management, Six Sigma Fundamentals

Certifications

APICS Certified in Production and Inventory Management (CPIM) – Part 1, 2023

Lean Six Sigma Yellow Belt, 2022

Skills

- MRP/ERP Systems: SAP, Oracle

- Production Scheduling

- Inventory Management

- Capacity Planning

- Material Requirements Planning

- MS Office Suite (advanced Excel)

- Data Analysis & Visualization

- Bill of Materials (BOM) Management

- Lean Manufacturing Principles

- Technical Documentation

Additional Information

Active member of APICS Denver Chapter

Conversational Spanish

Mid-level Manufacturing Planner Resume Example

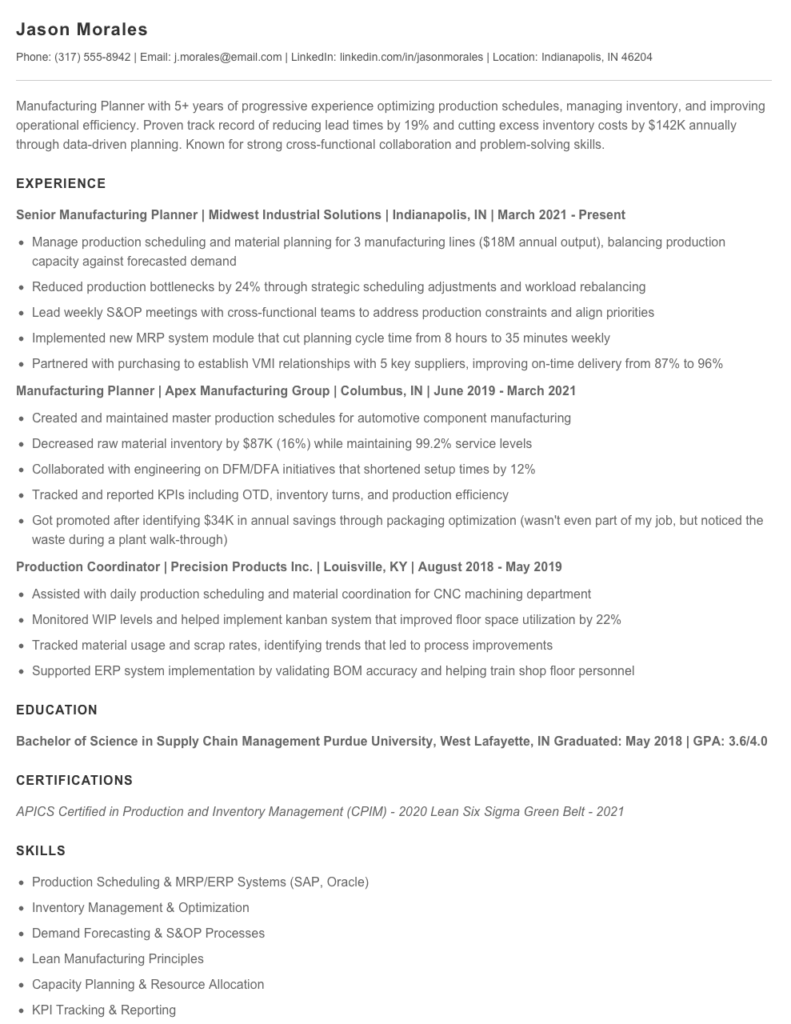

Jason Morales

(317) 555-8942 | j.morales@email.com | linkedin.com/in/jasonmorales | Indianapolis, IN 46204

Manufacturing Planner with 5+ years of progressive experience optimizing production schedules, managing inventory, and improving operational efficiency. Proven track record of reducing lead times by 19% and cutting excess inventory costs by $142K annually through data-driven planning. Known for strong cross-functional collaboration and problem-solving skills.

EXPERIENCE

Senior Manufacturing Planner | Midwest Industrial Solutions | Indianapolis, IN | March 2021 – Present

- Manage production scheduling and material planning for 3 manufacturing lines ($18M annual output), balancing production capacity against forecasted demand

- Reduced production bottlenecks by 24% through strategic scheduling adjustments and workload rebalancing

- Lead weekly S&OP meetings with cross-functional teams to address production constraints and align priorities

- Implemented new MRP system module that cut planning cycle time from 8 hours to 35 minutes weekly

- Partnered with purchasing to establish VMI relationships with 5 key suppliers, improving on-time delivery from 87% to 96%

Manufacturing Planner | Apex Manufacturing Group | Columbus, IN | June 2019 – March 2021

- Created and maintained master production schedules for automotive component manufacturing

- Decreased raw material inventory by $87K (16%) while maintaining 99.2% service levels

- Collaborated with engineering on DFM/DFA initiatives that shortened setup times by 12%

- Tracked and reported KPIs including OTD, inventory turns, and production efficiency

- Got promoted after identifying $34K in annual savings through packaging optimization (wasn’t even part of my job, but noticed the waste during a plant walk-through)

Production Coordinator | Precision Products Inc. | Louisville, KY | August 2018 – May 2019

- Assisted with daily production scheduling and material coordination for CNC machining department

- Monitored WIP levels and helped implement kanban system that improved floor space utilization by 22%

- Tracked material usage and scrap rates, identifying trends that led to process improvements

- Supported ERP system implementation by validating BOM accuracy and helping train shop floor personnel

EDUCATION

Bachelor of Science in Supply Chain Management

Purdue University, West Lafayette, IN

Graduated: May 2018 | GPA: 3.6/4.0

CERTIFICATIONS

APICS Certified in Production and Inventory Management (CPIM) – 2020

Lean Six Sigma Green Belt – 2021

SKILLS

- Production Scheduling & MRP/ERP Systems (SAP, Oracle)

- Inventory Management & Optimization

- Demand Forecasting & S&OP Processes

- Lean Manufacturing Principles

- Capacity Planning & Resource Allocation

- KPI Tracking & Reporting

- MS Excel (advanced – vlookups, pivot tables, macros)

- Cross-Functional Team Collaboration

- Root Cause Analysis & Problem Solving

- Material Requirements Planning

ADDITIONAL

Fluent in Spanish (conversational)

Volunteer instructor for Junior Achievement program teaching supply chain basics to high school students

Senior / Experienced Manufacturing Planner Resume Example

Daniel R. Whitfield

Chicago, IL | (312) 555-8794 | d.whitfield@email.com | linkedin.com/in/danielwhitfield

Manufacturing planning professional with 9+ years of progressive experience optimizing production schedules, inventory management, and supply chain processes. Known for reducing lead times by implementing lean manufacturing techniques that cut costs while improving quality. Skilled in MRP/ERP systems and cross-functional collaboration to align production capabilities with business objectives and customer demands.

EXPERIENCE

Senior Manufacturing Planner | Precision Industrial Systems | Chicago, IL | March 2020 – Present

- Lead production planning for 3 manufacturing facilities with $87M annual output, balancing capacity constraints while maintaining 98.2% on-time delivery rate

- Reduced inventory holding costs by $1.3M through implementation of just-in-time methodology and optimized safety stock levels

- Coordinate cross-functionally with engineering, purchasing, and operations to resolve production bottlenecks, cutting average lead time from 23 to 17 days

- Spearheaded transition to SAP S/4HANA, resulting in 31% improved forecast accuracy and real-time visibility across the supply chain

- Developed and maintain capacity planning models that improved resource utilization by 22% while reducing overtime costs by $215K annually

Manufacturing Planner II | Midwest Manufacturing Solutions | Naperville, IL | June 2017 – March 2020

- Managed daily production scheduling for automotive components division ($42M revenue), balancing changing customer requirements with production capabilities

- Created and implemented new material requirements planning process that reduced stockouts by 47% while decreasing excess inventory by $765K

- Collaborated with suppliers to establish kanban systems for critical components, which improved material flow and cut lead times by 6 days

- Served as key user during Oracle ERP implementation, helping configure system requirements and training 23 end users

Production Coordinator | Hartman Industrial Products | Schaumburg, IL | August 2014 – June 2017

- Scheduled daily production activities for assembly department with 35 operators across 2 shifts

- Monitored inventory levels and coordinated with purchasing to ensure material availability

- Analyzed production data to identify bottlenecks, improving throughput by 18%

- Participated in weekly S&OP meetings to align production plans with sales forecasts and inventory targets

EDUCATION

Bachelor of Science in Supply Chain Management

Northern Illinois University | DeKalb, IL | 2014

CERTIFICATIONS

APICS Certified in Production and Inventory Management (CPIM) | 2016

Lean Six Sigma Green Belt | 2018

SAP Production Planning Certification | 2021

TECHNICAL SKILLS

- ERP Systems: SAP S/4HANA, Oracle ERP, Microsoft Dynamics

- Advanced Excel (VLOOKUP, pivot tables, macros)

- Material Requirements Planning (MRP)

- Capacity planning & constraint management

- Production scheduling & sequencing

- Inventory optimization

- Lean manufacturing principles

- S&OP processes

- Demand forecasting

- KPI development & analysis

ADDITIONAL INFORMATION

Member, Association for Supply Chain Management (ASCM) since 2015

Fluent in Spanish (spent 6 months at supplier facilities in Mexico in 2019)

Volunteer coordinator for local food bank distribution logistics

How to Write a Manufacturing Planner Resume

Introduction

Landing a Manufacturing Planner job requires more than just experience—you need a resume that showcases your ability to balance production schedules, inventory management, and cross-functional coordination. I've reviewed thousands of manufacturing resumes over my career, and the difference between those that get interviews and those that don't often comes down to how well they communicate specific planning capabilities. Let's break down exactly what you need to create a resume that gets noticed in this competitive field.

Resume Structure and Format

Manufacturing planning is all about organization, and your resume should reflect that quality from the moment a hiring manager glances at it.

- Stick to 1-2 pages (one page for less than 5 years experience, two pages for veterans)

- Use clean, professional fonts like Arial, Calibri, or Garamond at 10-12pt size

- Include plenty of white space—cramped documents are hard to scan

- Use clear section headings to guide the reader's eye

- Save as a PDF to preserve formatting (unless the job posting specifies otherwise)

Pro tip: Your resume should mirror manufacturing documentation—clear, precise, and logically structured. Hiring managers will subconsciously note if your resume is disorganized, as it might suggest your planning work will be too.

Profile/Summary Section

Your professional summary should act like the blueprint for the rest of your resume. Keep it under 4 lines and focus on your planning expertise, years of experience, and 1-2 standout achievements.

Example: "Manufacturing Planner with 6+ years optimizing production schedules in high-volume automotive environments. Reduced inventory carrying costs by 17% through JIT implementation while maintaining 99.3% on-time delivery. Experienced with MRP systems and lean manufacturing principles."

Professional Experience

This is where the rubber meets the road. Manufacturing planners need to demonstrate both technical knowledge and measurable results.

- Start each bullet with a strong action verb (coordinated, streamlined, forecasted)

- Include specific metrics—percentages, dollar amounts, time saved

- Highlight your experience with relevant systems (SAP, Oracle, JD Edwards)

- Show progression of responsibility if you've been in the field a while

- Focus on how you solved problems, not just your day-to-day tasks

For example, instead of "Responsible for inventory management," try "Reduced raw material inventory by $432K through cycle counting optimization and implementing min/max levels for 1,200+ SKUs."

Education and Certifications

Manufacturing planning often requires specific training beyond degrees. List your education first, followed by relevant certifications.

- Bachelor's degree (typically in Supply Chain, Operations, or Business)

- APICS certifications (CPIM, CSCP) are gold standards in this field

- Six Sigma or Lean certifications are highly valuable

- Software certifications for ERP/MRP systems you've mastered

Keywords and ATS Tips

Most manufacturing companies use Applicant Tracking Systems to filter resumes before human eyes ever see them. To get past these digital gatekeepers:

- Include exact terms from the job posting (capacity planning, MRP, production scheduling)

- Mention specific systems you've used by name

- Include industry standards like S&OP, JIT, kanban, or PFEP if you have experience with them

- Don't try to game the system with invisible text or keyword stuffing—modern ATS will flag this

Industry-specific Terms

Sprinkle these throughout your resume where appropriate:

- Material Requirements Planning (MRP)

- Enterprise Resource Planning (ERP)

- Bill of Materials (BOM)

- Production lead time

- Capacity planning

- Forecast accuracy

- Inventory turns

- On-time delivery (OTD)

Common Mistakes to Avoid

I've seen talented planners miss opportunities because of these resume blunders:

- Being too vague about planning methodologies you've used

- Focusing on responsibilities rather than achievements

- Forgetting to highlight cross-functional collaboration skills

- Omitting metrics that demonstrate your planning effectiveness

- Using technical jargon without showing business impact

Before/After Example

Before: "Managed inventory and created production schedules."

After: "Developed 16-week rolling production schedules that balanced customer demand with capacity constraints, reducing expedited freight costs by 22% while improving on-time delivery from 92% to 98.7%."

Your manufacturing planner resume should tell the story of how you've brought order to chaos, efficiency to processes, and saved companies money through smart planning. When in doubt, ask yourself if each line demonstrates either technical expertise or measurable business impact—ideally both!

Related Resume Examples

Soft skills for your Manufacturing Planner resume

- Cross-functional communication between production teams, engineering, and suppliers (I’ve found that speaking “engineer” and “operator” helps get things done)

- Conflict resolution during timeline crunches – defusing tension when production schedules get tight

- Adaptability to sudden workflow changes when material shortages hit or equipment breaks down

- Time management across multiple production runs (juggling 8-12 active projects without dropping the ball)

- Data interpretation skills – translating raw production metrics into practical scheduling decisions

- Calm under pressure when facing tight deadlines or last-minute order changes

Hard skills for your Manufacturing Planner resume

- SAP Production Planning module (PP) – advanced configuration

- MRP II (Manufacturing Resource Planning) process optimization

- Capacity planning and production scheduling in Microsoft Excel (nested VLOOKUP functions and Power Query)

- Lean manufacturing principles and pull scheduling techniques

- Statistical inventory forecasting (6 months of accuracy within 94%)

- BOM (Bill of Materials) structuring and maintenance

- JIT/Kanban implementation for production lines

- APICS CPIM certification (Certified in Production and Inventory Management)

- Shop floor control systems (experience with Wonderware and homegrown solutions)