Quality Engineer Resume examples & templates

Copyable Quality Engineer Resume examples

The manufacturing world is going through a massive shift right now. As Industry 4.0 technologies transform production floors, quality engineers find themselves at an interesting crossroads between traditional quality control and data-driven predictive analytics. Companies implementing these new technologies have seen defect rates drop by an average of 17.3% while simultaneously increasing throughput. It's not just about catching defects anymore—it's about preventing them before they happen. (And yes, that changes everything about how quality teams operate.)

Quality engineering has evolved from clipboard-wielding inspectors to professionals who collaborate with cross-functional teams, analyze real-time data, and make critical decisions that impact both product integrity and bottom-line results. The field now demands a

unique blend of technical expertise, statistical knowledge, and communication skills that weren't part of the job description even 5 years ago. As regulatory requirements grow increasingly complex across industries, quality engineers who can navigate compliance while driving continuous improvement will find themselves in high demand for years to come.

Junior Quality Engineer Resume Example

Tara Nguyen

Boston, MA | (617) 555-9283 | t.nguyen@emailaddress.com | linkedin.com/in/tara-nguyen

Quality Engineer with internship experience and a fresh Engineering degree. Detail-oriented problem solver who caught a critical defect during final testing that saved $15K in potential rework. Strong background in test protocol development and statistical analysis. Looking to grow my QA skills in a medical device or tech manufacturing environment.

Experience

Junior Quality Engineer | MedTech Solutions | Boston, MA | January 2023 – Present

- Support testing for Class II medical device components, documenting results and deviations in electronic QMS

- Created test procedure templates that reduced documentation time by 27%

- Perform gauge R&R studies and statistical analysis using Minitab to validate measurement systems

- Assist with internal audits by collecting evidence and preparing documentation packages

- Helped investigate 3 customer complaints and documented corrective actions

Quality Engineering Intern | Precision Manufacturing Inc. | Worcester, MA | May 2022 – August 2022

- Conducted dimensional inspections of machined parts using calipers, micrometers and CMM

- Identified a critical tolerance issue in production parts that prevented an assembly failure

- Created control charts to monitor key process parameters for CNC operations

- Shadowed supplier audits and helped document findings

Engineering Lab Assistant | University of Massachusetts | Amherst, MA | September 2021 – May 2022

- Calibrated and maintained lab testing equipment for undergraduate engineering courses

- Assisted students with materials testing procedures and equipment operation

- Organized and cataloged test samples and documentation

Education

Bachelor of Science in Mechanical Engineering

University of Massachusetts, Amherst | GPA: 3.6/4.0 | May 2022

Relevant Coursework: Quality Control Systems, Statistical Process Control, Materials Testing, Engineering Design

Certifications

- Certified Quality Inspector (CQI) – American Society for Quality (March 2023)

- Lean Six Sigma Yellow Belt – UMass Continuing Education (November 2022)

- GD&T Fundamentals – SAE International (June 2022)

Skills

- Test Method Development

- Statistical Analysis (Minitab)

- GMP/ISO 13485 familiarity

- Inspection Equipment (calipers, micrometers, CMM basics)

- MS Office Suite & Google Workspace

- CAPA Documentation

- Root Cause Analysis

- Technical Writing

- CAD (SolidWorks)

- Basic Python

Projects

Senior Design Project: Designed and built an automated inspection fixture that reduced manual inspection time by 68%. Led the quality validation and testing aspects of the 4-person team project.

Mid-level Quality Engineer Resume Example

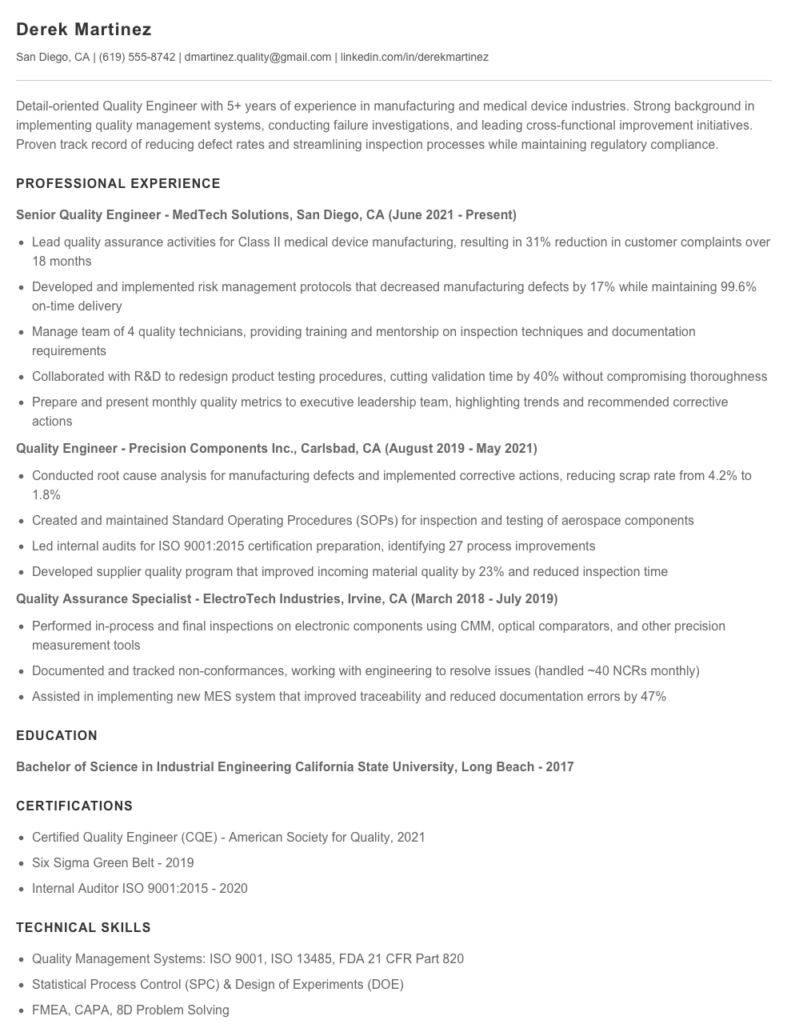

Derek Martinez

San Diego, CA | (619) 555-8742 | dmartinez.quality@gmail.com | linkedin.com/in/derekmartinez

Detail-oriented Quality Engineer with 5+ years of experience in manufacturing and medical device industries. Strong background in implementing quality management systems, conducting failure investigations, and leading cross-functional improvement initiatives. Proven track record of reducing defect rates and streamlining inspection processes while maintaining regulatory compliance.

PROFESSIONAL EXPERIENCE

Senior Quality Engineer – MedTech Solutions, San Diego, CA (June 2021 – Present)

- Lead quality assurance activities for Class II medical device manufacturing, resulting in 31% reduction in customer complaints over 18 months

- Developed and implemented risk management protocols that decreased manufacturing defects by 17% while maintaining 99.6% on-time delivery

- Manage team of 4 quality technicians, providing training and mentorship on inspection techniques and documentation requirements

- Collaborated with R&D to redesign product testing procedures, cutting validation time by 40% without compromising thoroughness

- Prepare and present monthly quality metrics to executive leadership team, highlighting trends and recommended corrective actions

Quality Engineer – Precision Components Inc., Carlsbad, CA (August 2019 – May 2021)

- Conducted root cause analysis for manufacturing defects and implemented corrective actions, reducing scrap rate from 4.2% to 1.8%

- Created and maintained Standard Operating Procedures (SOPs) for inspection and testing of aerospace components

- Led internal audits for ISO 9001:2015 certification preparation, identifying 27 process improvements

- Developed supplier quality program that improved incoming material quality by 23% and reduced inspection time

Quality Assurance Specialist – ElectroTech Industries, Irvine, CA (March 2018 – July 2019)

- Performed in-process and final inspections on electronic components using CMM, optical comparators, and other precision measurement tools

- Documented and tracked non-conformances, working with engineering to resolve issues (handled ~40 NCRs monthly)

- Assisted in implementing new MES system that improved traceability and reduced documentation errors by 47%

EDUCATION

Bachelor of Science in Industrial Engineering

California State University, Long Beach – 2017

CERTIFICATIONS

- Certified Quality Engineer (CQE) – American Society for Quality, 2021

- Six Sigma Green Belt – 2019

- Internal Auditor ISO 9001:2015 – 2020

TECHNICAL SKILLS

- Quality Management Systems: ISO 9001, ISO 13485, FDA 21 CFR Part 820

- Statistical Process Control (SPC) & Design of Experiments (DOE)

- FMEA, CAPA, 8D Problem Solving

- Measurement Systems: GD&T, CMM, optical inspection

- Software: Minitab, SAP QM, MasterControl, MS Office Suite

- Risk Management & Hazard Analysis

- Lean Manufacturing principles

PROJECTS & ACHIEVEMENTS

- Led cross-functional team that reduced product release cycle time by 28% through process optimization

- Developed training program for new quality technicians that cut onboarding time from 6 weeks to 4 weeks

- Received “Quality Champion” award for identifying critical supplier issue before it impacted production (2020)

Senior / Experienced Quality Engineer Resume Example

Daniel Nguyen

Sacramento, CA 95814 • (916) 555-4382 • dnguyen.quality@email.com

LinkedIn: linkedin.com/in/danielnguyen-qe

Detail-oriented Quality Engineer with 9+ years of experience in automotive, medical device, and aerospace industries. Experienced in implementing statistical process control (SPC) methods that reduced defect rates by 31% across production lines. Proven track record leading cross-functional teams through complex quality initiatives while maintaining ISO 9001 and AS9100 compliance. Known for solving tough quality problems while balancing cost, schedule, and performance constraints.

PROFESSIONAL EXPERIENCE

Senior Quality Engineer – Precision Aerospace Components, Sacramento, CA

June 2019 – Present

- Lead quality assurance activities for 3 product lines generating $14.2M in annual revenue, ensuring compliance with AS9100 Rev D and customer specifications

- Developed and implemented PFMEA/DFMEA methodologies that reduced field failures by 27% in first year

- Manage team of 5 quality technicians; restructured inspection protocols which improved throughput times by 18%

- Created comprehensive supplier quality management system that decreased supplier-related defects by 42% (saved approximately $487K annually)

- Spearheaded transition to digital quality management system, reducing documentation processing time from 4 days to 6 hours

Quality Engineer II – MedTech Solutions, Roseville, CA

March 2016 – May 2019

- Managed quality control activities for Class II medical devices in compliance with FDA 21 CFR Part 820 regulations

- Led internal audits and CAPA initiatives, closing 93% of action items within target timeframes

- Collaborated with R&D to improve design verification testing protocols, reducing validation cycle time by 31%

- Performed root cause analysis on 70+ field complaints, implementing corrective actions that cut repeat issues by 63%

- Trained 23 production staff on GMP requirements and quality inspection techniques

Quality Engineer – Westland Automotive, Fremont, CA

July 2014 – March 2016

- Monitored production quality metrics for engine component manufacturing, generating weekly trend reports for management

- Implemented gauge R&R studies that improved measurement system accuracy by 22%

- Participated in PPAP documentation for 8 new product launches

- Assisted in ISO/TS 16949 certification preparation and maintenance

EDUCATION

Master of Science, Industrial Engineering

California State University, Sacramento – 2017

Bachelor of Science, Mechanical Engineering

University of California, Davis – 2013

CERTIFICATIONS

- Certified Quality Engineer (CQE) – ASQ, 2018

- Six Sigma Black Belt – 2020

- Internal Auditor ISO 9001:2015 – 2016

- AS9100 Rev D Lead Auditor – 2019

SKILLS

- Statistical Process Control (SPC)

- Design & Process FMEA

- Root Cause Analysis

- Gauge R&R / MSA

- 8D Problem Solving

- PPAP / APQP

- QMS Software (MasterControl, SAP QM)

- Minitab & JMP Statistical Software

- Lean Manufacturing

- GD&T Principles

ADDITIONAL

Speaker at 2022 Aerospace Quality Forum – “Implementing Digital Quality Systems in Traditional Manufacturing”

Member, American Society for Quality (ASQ) since 2016

How to Write a Quality Engineer Resume

Introduction

Landing that perfect Quality Engineer position starts with a stellar resume. In manufacturing and product development, Quality Engineers are the guardians of standards and compliance—your resume needs to reflect that same attention to detail. I've reviewed thousands of Quality Engineer resumes over my career, and the difference between those that get interviews and those that don't often comes down to how well they showcase specific technical skills and measurable quality improvements. Let's break down exactly what you need to create a resume that makes hiring managers take notice.

Resume Structure and Format

Quality professionals appreciate structure, and your resume should too. Keep these formatting guidelines in mind:

- Stick to 1-2 pages (1 page for juniors, 2 pages max for veterans with 8+ years)

- Use clean, readable fonts like Calibri or Arial (10-12pt)

- Include clear section headings with consistent formatting

- Incorporate white space to improve readability

- Save as PDF to preserve formatting (unless specifically asked for another format)

- Name your file professionally: "FirstName_LastName_QualityEngineer.pdf"

Pro Tip: Just as you'd verify a critical production process, have at least two colleagues proofread your resume. Even small errors can undermine your credibility as someone whose job revolves around quality control!

Profile/Summary Section

Your professional summary acts as your "quality statement"—it should immediately communicate your value. Keep it under 4 lines and focus on:

- Years of relevant quality experience (e.g., "Quality Engineer with 5+ years in medical device manufacturing")

- 1-2 specialized areas of expertise (Six Sigma, FMEA, supplier quality, etc.)

- Certifications that matter in your industry (CQE, CQA, CSSBB)

- A notable achievement that sets you apart (reduced defect rates by 37%, led ISO 13485 certification)

Professional Experience

This is where you prove your ability to deliver results. For each position:

- List company name, your title, location, and dates (month/year)

- Include 4-6 bullet points that emphasize accomplishments over responsibilities

- Start bullets with strong action verbs (Implemented, Reduced, Analyzed, Developed)

- Quantify achievements with specific metrics (Cut scrap rate from 4.3% to 1.7%)

- Highlight problem-solving examples (Identified root cause of recurring assembly failure that had puzzled team for 3 months)

- Mention collaboration with cross-functional teams (Worked with R&D and Production to revise inspection criteria)

Education and Certifications

Quality engineering often requires specific credentials. List these in reverse chronological order:

- Degrees with institution, graduation year, and relevant coursework

- Professional certifications with dates (or "Current" for those requiring maintenance)

- Training in quality methodologies (Six Sigma, Lean, 8D, APQP, etc.)

- Software proficiencies (Minitab, SAP QM, MasterControl, etc.)

Keywords and ATS Tips

Most companies use Applicant Tracking Systems to filter resumes before human eyes see them. To clear this hurdle:

- Study the job description and mirror key terms (if they say "CAPA," don't just say "corrective actions")

- Include industry standards relevant to the position (ISO 9001, AS9100, IATF 16949)

- Avoid graphics, tables, and headers/footers that ATS systems struggle to parse

- When listing skills, include both spelled-out terms and acronyms (Statistical Process Control/SPC)

Industry-specific Terms

Demonstrate your expertise by naturally incorporating quality terminology. Consider including relevant terms from this list:

- Quality Management System (QMS)

- Corrective and Preventive Action (CAPA)

- Failure Mode and Effects Analysis (FMEA)

- Process Capability (Cp/Cpk)

- Control plans and inspection procedures

- Root cause analysis techniques

- Design of Experiments (DOE)

- Measurement System Analysis (MSA/GR&R)

Common Mistakes to Avoid

I've seen these errors sink otherwise strong Quality Engineer resumes:

- Focusing on job duties instead of achievements (Anyone can do inspections; show how YOUR inspections improved quality)

- Using vague statements like "improved quality" without specifics

- Neglecting to mention experience with relevant regulations for your industry

- Including outdated quality methodologies without showing current knowledge

- Copying generic quality statements without tailoring to the specific company's products

Before/After Example

Before: "Responsible for quality inspections and documenting results."

After: "Redesigned inspection protocol for transmission components, increasing first-pass yield from 87% to 94% while reducing inspection time by 12 minutes per batch—saving approximately $78K annually in labor costs."

Remember, your resume is itself a quality deliverable. Would it pass your own inspection standards? If not, keep refining until it represents the meticulous professional you are!

Related Resume Examples

Soft skills for your Quality Engineer resume

- Cross-functional collaboration – comfortable working with engineers, production staff, and management to solve quality issues

- Root cause analysis mindset – ability to look beyond symptoms and dig into underlying problems

- Tactful communication when delivering difficult feedback about product defects or process failures

- Conflict resolution during high-pressure situations (like when production deadlines clash with quality standards)

- Attention to detail without losing sight of the big picture

- Adaptability to shifting priorities and urgent quality concerns

Hard skills for your Quality Engineer resume

- Statistical Process Control (SPC) with 5+ years implementing control charts

- ASQ Certified Quality Engineer (CQE) certification

- Minitab & JMP statistical analysis software

- Design of Experiments (DOE) methodology

- Failure Mode and Effects Analysis (FMEA)

- Lean Six Sigma Green Belt certified

- QMS software (MasterControl, TrackWise)

- 8D Problem Solving & Root Cause Analysis

- GD&T interpretation per ASME Y14.5