Production Operator Resume examples & templates

Copyable Production Operator Resume examples

What keeps the world's most important products flowing from factories to store shelves? Behind every successful manufacturing operation is a team of skilled Production Operators—the backbone of industries from pharmaceuticals to plastics, food to furniture. These professionals aren't just button-pushers; they're quality guardians, efficiency experts, and problem-solvers working at the critical intersection of technology and craftsmanship. With manufacturing automation accelerating (the industrial robot market grew by 17.8% in 2023 alone), today's Production Operators need technical savvy alongside traditional skills.

The role has evolved dramatically over the past decade. Gone are the days of purely manual assembly lines. Modern Production Operators work with sophisticated equipment, maintain digital production records, and often collaborate with engineers to improve processes. Many companies now seek operators with specialized certifications and cross-functional capabilities—someone who can not only run a machine but troubleshoot it when problems arise. As manufacturing continues its tech transformation, Production Operators who embrace continuous learning will find themselves at the forefront of an industry that literally shapes our physical world.

Junior Production Operator Resume Example

Marcus Thompson

Phone: (509) 385-7912 • Email: marcus.thompson@gmail.com

Portland, OR 97214 • linkedin.com/in/marcusthompson

Detail-oriented Production Operator with 1+ year of experience in manufacturing environments. Quick learner who maintains high quality standards while meeting production targets. Experienced with basic equipment maintenance and safety protocols. Looking to grow in a manufacturing role where I can contribute to efficient operations.

EXPERIENCE

Production Operator – Pacific Northwest Manufacturing, Portland, OR

March 2023 – Present

- Monitor and operate 3 production lines producing electronic components with 97% quality rate

- Perform routine equipment checks and basic maintenance, reducing downtime by 14%

- Document production data and quality issues in SAP system for 400+ daily units

- Collaborate with team of 12 operators to meet daily production goals consistently

- Implemented organization system for tools that cut average setup time from 12 to 8 minutes

Production Assistant – Westside Manufacturing Co., Beaverton, OR

August 2022 – February 2023

- Assisted senior operators with assembly and packaging of consumer products

- Performed quality checks on finished products, catching avg. 7 defects per shift

- Maintained clean work environment according to 5S standards

- Helped load/unload materials from delivery trucks using pallet jacks

Warehouse Associate (Part-time) – Quick Ship Logistics, Portland, OR

May 2022 – August 2022

- Picked and packed orders for shipping while maintaining 98.5% accuracy rate

- Organized inventory and helped with cycle counts during monthly audits

- Used handheld scanners and basic warehouse management software

EDUCATION

Associate of Applied Science, Manufacturing Technology

Portland Community College, Portland, OR

Graduated: May 2022

Certifications:

- OSHA 10-Hour General Industry Safety (2022)

- Forklift Operator Certification (2022)

- Basic First Aid and CPR (2023)

SKILLS

- Equipment operation (assembly lines, packaging machines)

- Quality control & inspection

- Basic troubleshooting

- Material handling

- Inventory management

- SAP (basic user level)

- Microsoft Office (Word, Excel)

- Time management

- Team collaboration

- Attention to detail

Mid-level Production Operator Resume Example

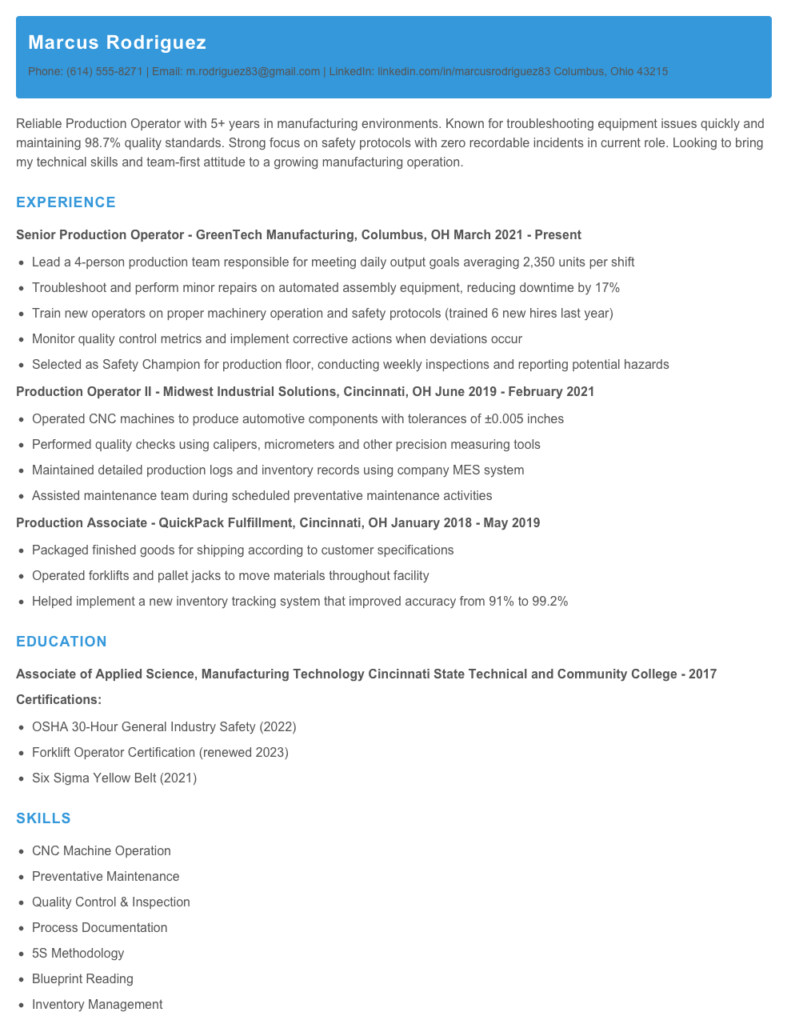

Marcus Rodriguez

Phone: (614) 555-8271 | Email: m.rodriguez83@gmail.com | LinkedIn: linkedin.com/in/marcusrodriguez83

Columbus, Ohio 43215

Reliable Production Operator with 5+ years in manufacturing environments. Known for troubleshooting equipment issues quickly and maintaining 98.7% quality standards. Strong focus on safety protocols with zero recordable incidents in current role. Looking to bring my technical skills and team-first attitude to a growing manufacturing operation.

EXPERIENCE

Senior Production Operator – GreenTech Manufacturing, Columbus, OH

March 2021 – Present

- Lead a 4-person production team responsible for meeting daily output goals averaging 2,350 units per shift

- Troubleshoot and perform minor repairs on automated assembly equipment, reducing downtime by 17%

- Train new operators on proper machinery operation and safety protocols (trained 6 new hires last year)

- Monitor quality control metrics and implement corrective actions when deviations occur

- Selected as Safety Champion for production floor, conducting weekly inspections and reporting potential hazards

Production Operator II – Midwest Industrial Solutions, Cincinnati, OH

June 2019 – February 2021

- Operated CNC machines to produce automotive components with tolerances of ±0.005 inches

- Performed quality checks using calipers, micrometers and other precision measuring tools

- Maintained detailed production logs and inventory records using company MES system

- Assisted maintenance team during scheduled preventative maintenance activities

Production Associate – QuickPack Fulfillment, Cincinnati, OH

January 2018 – May 2019

- Packaged finished goods for shipping according to customer specifications

- Operated forklifts and pallet jacks to move materials throughout facility

- Helped implement a new inventory tracking system that improved accuracy from 91% to 99.2%

EDUCATION

Associate of Applied Science, Manufacturing Technology

Cincinnati State Technical and Community College – 2017

Certifications:

- OSHA 30-Hour General Industry Safety (2022)

- Forklift Operator Certification (renewed 2023)

- Six Sigma Yellow Belt (2021)

SKILLS

- CNC Machine Operation

- Preventative Maintenance

- Quality Control & Inspection

- Process Documentation

- 5S Methodology

- Blueprint Reading

- Inventory Management

- SAP Manufacturing Module

- Team Leadership

- Mechanical Troubleshooting

ADDITIONAL INFORMATION

Available for all shifts including nights and weekends. Bilingual (English/Spanish).

Senior / Experienced Production Operator Resume Example

Michael R. Dawson

Portland, OR 97214 • (503) 555-8712 • mdawson.pdo@email.com • linkedin.com/in/michaeldawson

Dedicated Production Operator with 11+ years of progressive manufacturing experience in high-volume environments. Known for optimizing production workflows that reduced downtime by 27% and implementing preventative maintenance schedules that extended equipment life. Strong troubleshooting abilities with expertise in lean manufacturing principles and safety protocols. Successfully trained 24 junior operators while maintaining 99.3% quality standards.

PROFESSIONAL EXPERIENCE

Senior Production Operator – Cascade Manufacturing Solutions, Portland, OR (June 2018 – Present)

- Lead a 5-person production team that exceeded quarterly targets by 14% through implementation of visual management systems and daily standups

- Troubleshoot complex machinery issues on 3 production lines, cutting average repair time from 4.3 hours to 1.8 hours

- Spearheaded transition to new ERP system for production tracking, training 12 colleagues on proper documentation procedures

- Reduced material waste by 22% by refining changeover procedures and standardizing work instructions

- Serve as safety ambassador, conducting weekly inspections that helped maintain a perfect safety record (1,087 days without a lost-time incident)

Production Operator II – Pacific Northwest Fabricators, Vancouver, WA (March 2015 – May 2018)

- Operated CNC machinery for precision parts manufacturing, maintaining tolerances within ±0.005″

- Performed quality checks on 175+ units per shift, identifying and resolving recurring defects that improved first-pass yield from 91% to 97%

- Collaborated with engineering team to modify fixture designs, increasing production throughput by 31%

- Mentored 7 new hires on equipment operation and company procedures, all of whom were retained beyond 6 months

Production Associate – Meridian Industries, Beaverton, OR (August 2012 – February 2015)

- Operated packaging equipment for consumer goods, consistently exceeding daily production goals by 7-12%

- Conducted routine maintenance on conveyor systems and packaging machinery

- Participated in 5S implementation team that reorganized work areas and reduced changeover times by 24%

- Maintained detailed production logs and communicated shift issues to incoming personnel

EDUCATION & CERTIFICATIONS

Associate’s Degree, Manufacturing Technology

Portland Community College, Portland, OR (2012)

Certifications:

- OSHA 30-Hour General Industry Safety (2020)

- Lean Six Sigma Yellow Belt (2019)

- Certified Production Technician (CPT) – Manufacturing Skill Standards Council (2017)

- Forklift Operator Certification (renewed 2021)

TECHNICAL SKILLS

- Equipment: CNC machining, hydraulic presses, industrial conveyor systems, packaging equipment

- Software: SAP Manufacturing module, MS Excel (advanced), JD Edwards ERP, AutoCAD (basic)

- Quality Control: SPC methods, GD&T interpretation, caliper and micrometer usage

- Process Improvement: 5S, Kaizen, JIT inventory, root cause analysis

- Safety: Lock-out/tag-out procedures, confined space protocols, PPE compliance

ADDITIONAL INFORMATION

Volunteer instructor for weekend manufacturing workshops at Portland Community College (2019-present)

Bilingual: English and Spanish (conversational)

How to Write a Production Operator Resume

Introduction

Landing a production operator job means showing employers you can handle the fast-paced environment of manufacturing floors. Your resume is your first chance to prove you've got the technical skills, attention to detail, and reliability they need. I've reviewed thousands of production resumes over my 15 years in hiring and recruitment, and the difference between getting an interview and getting ignored often comes down to how you present your experience.

Resume Structure and Format

Keep your production operator resume clean and easy to scan—just like you'd keep your workstation. Aim for 1-2 pages max (one page is perfect for those with less than 5 years of experience).

- Stick with standard fonts like Arial or Calibri in 10-12pt size

- Use consistent bullet points and heading styles

- Include plenty of white space—crowded pages are hard to read

- Save as a PDF unless specifically asked for a different format

- Name your file professionally (JohnSmith_ProductionOperator.pdf)

If applying for positions at larger manufacturers, your resume will likely be scanned by ATS software before human eyes ever see it. Simple formatting without tables, headers/footers, or graphics will ensure your resume gets through the digital gatekeeper.

Profile/Summary Section

Start with a brief punch—3-4 lines that summarize your experience and biggest strengths. This isn't where you tell them what you want; it's where you tell them what you offer.

For example:

"Production operator with 4+ years in high-volume automotive parts manufacturing. Experienced in operating CNC equipment with 99.3% quality rating. Reduced line downtime by 17% through preventative maintenance procedures. OSHA certified with perfect safety record."

Professional Experience

Here's where you shine! Don't just list job duties—highlight your wins and how you made processes better.

- Start each bullet with a strong action verb (monitored, operated, maintained)

- Include specific machines you've operated (injection molding machines, lathes, CNC)

- Mention numbers whenever possible (produced 750+ units per shift, maintained 98.7% quality)

- Show progression if you've been promoted (from line worker to team lead)

- Include examples of problem-solving (spotted recurring quality issue, suggested fix that saved $12K)

Education and Certifications

Many production jobs prioritize skills over formal education, but still include:

- High school diploma or GED

- Technical training or vocational certificates

- Relevant certifications (forklift operation, OSHA 10/30, Six Sigma)

- On-the-job training programs you've completed

If you're newer to the field, you can emphasize coursework related to manufacturing, mechanics, or industrial technology.

Keywords and ATS Tips

Big companies use Applicant Tracking Systems to filter resumes. To get past them:

- Match keywords from the job posting (if they say "quality control," use "quality control" not just "QC")

- Include industry-standard terms (preventative maintenance, lean manufacturing)

- Mention specific equipment mentioned in the job description

- List all relevant certifications using their full names and acronyms (Occupational Safety and Health Administration - OSHA)

Industry-specific Terms to Include

- Quality assurance/quality control

- Preventative maintenance

- Standard operating procedures (SOPs)

- 5S, Kaizen, or other lean principles you've used

- Specific machinery types (conveyor systems, robotics)

- Materials handling

- Production metrics (OEE, throughput, cycle time)

Common Mistakes to Avoid

- Being vague about technical skills (say exactly which machines you can operate)

- Focusing only on duties rather than achievements

- Omitting safety training or perfect attendance (huge selling points!)

- Using the same resume for different manufacturing environments

- Forgetting to mention soft skills like teamwork and communication

Before/After Example

Before: "Worked on assembly line making parts."

After: "Operated five-station assembly line producing automotive door panels, maintaining 99.1% quality rating while exceeding daily production targets by 12%. Implemented tool organization system that reduced changeover time from 45 to 28 minutes."

Remember, your resume should show you're reliable, detail-oriented, and capable—the exact qualities that make a great production operator. Customize it for each job, focusing on the specific skills and experience that particular employer values most.

Related Resume Examples

Soft skills for your Production Operator resume

- Cross-functional team cooperation – skilled at bridging gaps between maintenance, QA, and management

- Calm troubleshooting under pressure when equipment failures threaten production targets

- Process improvement mentality – able to spot inefficiencies after running the same line for months

- Quick adaptation to changing priorities (especially during shift transitions or emergency orders)

- Practical communication style that gets points across clearly to both veteran operators and newcomers

- Mentoring capability – comfortable teaching proper procedures to temps and new hires without micromanaging

Hard skills for your Production Operator resume

- CNC Machine Operation (Siemens 840D control systems)

- Quality Control Inspection using calipers, micrometers and CMM equipment

- Preventive Maintenance (PM) scheduling and execution

- SAP Manufacturing Module proficiency

- 5S and Kaizen implementation experience

- Forklift Operation Certification (Class III)

- Automated Packaging Systems troubleshooting

- Blueprint reading and GD&T interpretation

- OSHA Safety Standards compliance