Production Manager Resume examples & templates

Copyable Production Manager Resume examples

While software engineers orchestrate lines of code, Production Managers conduct a symphony of people, equipment, and processes. The two fields share surprising parallels—both require technical expertise, problem-solving abilities, and systems thinking—yet Production Managers operate in the tangible world where finished products emerge from raw materials. It's a career that blends analytical thinking with hands-on leadership, where efficiency improvements are measured not in milliseconds but in tangible outputs and team performance. In manufacturing environments especially, these professionals have seen their roles transform dramatically with the rise of Industry 4.0 technologies.

Recent Bureau of Labor Statistics data shows Production Managers earning a median annual salary of $103,150, reflecting the substantial responsibility they shoulder in today's complex manufacturing landscape. The job has evolved far beyond clipboard-wielding overseers; today's Production Managers are implementing predictive maintenance systems, integrating robotics, and managing increasingly automated workflows. As supply chains continue to face unprecedented challenges, Production Managers with both technical savvy and strong leadership capabilities will be uniquely positioned to guide manufacturing operations through the next decade of innovation and disruption.

Junior Production Manager Resume Example

Marcus Hernandez

Los Angeles, CA 90012 | (213) 555-7128 | m.hernandez91@email.com | linkedin.com/in/marcushernandez91

Production Manager with 2 years of manufacturing experience specializing in workflow optimization and team leadership. Reduced production bottlenecks by 17% at Westside Manufacturing through improved scheduling systems. Engineering background with hands-on technical skills complemented by strong communication abilities. Looking to grow in a fast-paced production environment where I can continue developing operational excellence.

Experience

Production Manager | Westside Manufacturing | Los Angeles, CA | March 2022 – Present

- Oversee daily operations for a 12-person production team manufacturing custom furniture components across two shift schedules

- Streamlined quality control process, cutting inspection time by 23% while maintaining 99.7% compliance rate

- Collaborated with supply chain team to reduce raw material inventory costs by $47,000 annually

- Implemented new production tracking system that improved on-time delivery from 82% to 94%

- Trained and mentored 4 production team members who were subsequently promoted to senior roles

Production Supervisor | Westside Manufacturing | Los Angeles, CA | June 2021 – March 2022

- Monitored production floor activities and helped resolve technical issues during manufacturing processes

- Created daily production reports and identified opportunities to improve efficiency

- Assisted in developing standard operating procedures for 3 new assembly processes

- Helped reduce machine downtime by 14% through better preventative maintenance scheduling

Production Assistant | ValTech Industries | San Diego, CA | August 2020 – May 2021

- Supported production operations by preparing materials, maintaining inventory records, and assisting with quality checks

- Participated in cross-functional team meetings to improve production flow

- Helped implement 5S workplace organization methods in packaging department

Education

Bachelor of Science in Industrial Engineering

California State University, Long Beach | Graduated: May 2020

Relevant coursework: Production Planning, Operations Management, Supply Chain Fundamentals

Certifications

- Lean Six Sigma Yellow Belt (2021)

- OSHA 30-Hour General Industry Safety (2020)

- Microsoft Excel Specialist (2019)

Skills

- Production Scheduling & Planning

- Team Leadership & Development

- Quality Control Processes

- Inventory Management

- Lean Manufacturing Principles

- ERP Systems (SAP basics)

- Process Improvement

- Cost Reduction Strategies

- MRP Software

- Microsoft Office Suite (Excel power user)

Additional

Bilingual: Fluent in English and Spanish

Volunteer Production Coordinator for annual LA Maker Faire (2021, 2022)

Mid-level Production Manager Resume Example

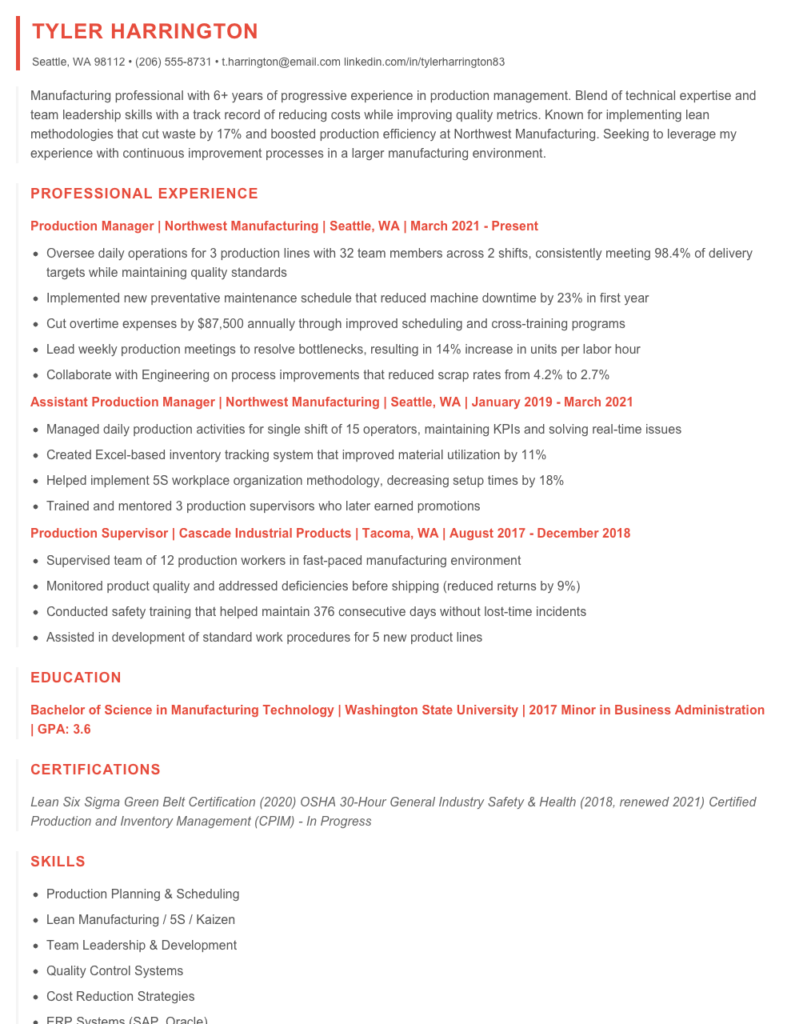

TYLER HARRINGTON

Seattle, WA 98112 • (206) 555-8731 • t.harrington@email.com

linkedin.com/in/tylerharrington83

Manufacturing professional with 6+ years of progressive experience in production management. Blend of technical expertise and team leadership skills with a track record of reducing costs while improving quality metrics. Known for implementing lean methodologies that cut waste by 17% and boosted production efficiency at Northwest Manufacturing. Seeking to leverage my experience with continuous improvement processes in a larger manufacturing environment.

PROFESSIONAL EXPERIENCE

Production Manager | Northwest Manufacturing | Seattle, WA | March 2021 – Present

- Oversee daily operations for 3 production lines with 32 team members across 2 shifts, consistently meeting 98.4% of delivery targets while maintaining quality standards

- Implemented new preventative maintenance schedule that reduced machine downtime by 23% in first year

- Cut overtime expenses by $87,500 annually through improved scheduling and cross-training programs

- Lead weekly production meetings to resolve bottlenecks, resulting in 14% increase in units per labor hour

- Collaborate with Engineering on process improvements that reduced scrap rates from 4.2% to 2.7%

Assistant Production Manager | Northwest Manufacturing | Seattle, WA | January 2019 – March 2021

- Managed daily production activities for single shift of 15 operators, maintaining KPIs and solving real-time issues

- Created Excel-based inventory tracking system that improved material utilization by 11%

- Helped implement 5S workplace organization methodology, decreasing setup times by 18%

- Trained and mentored 3 production supervisors who later earned promotions

Production Supervisor | Cascade Industrial Products | Tacoma, WA | August 2017 – December 2018

- Supervised team of 12 production workers in fast-paced manufacturing environment

- Monitored product quality and addressed deficiencies before shipping (reduced returns by 9%)

- Conducted safety training that helped maintain 376 consecutive days without lost-time incidents

- Assisted in development of standard work procedures for 5 new product lines

EDUCATION

Bachelor of Science in Manufacturing Technology | Washington State University | 2017

Minor in Business Administration | GPA: 3.6

CERTIFICATIONS

Lean Six Sigma Green Belt Certification (2020)

OSHA 30-Hour General Industry Safety & Health (2018, renewed 2021)

Certified Production and Inventory Management (CPIM) – In Progress

SKILLS

- Production Planning & Scheduling

- Lean Manufacturing / 5S / Kaizen

- Team Leadership & Development

- Quality Control Systems

- Cost Reduction Strategies

- ERP Systems (SAP, Oracle)

- Microsoft Office Suite (advanced Excel)

- Equipment Maintenance & Troubleshooting

- Safety Compliance & Training

- Process Improvement

ADDITIONAL INFORMATION

Member, Association for Manufacturing Excellence (AME)

Volunteer, Manufacturing Day Career Fair Organizer (2019-Present)

Senior / Experienced Production Manager Resume Example

DEREK MARTINEZ

Chicago, IL | (312) 555-8976 | d.martinez@email.com | linkedin.com/in/derekmartinez

PROFESSIONAL SUMMARY

Production Manager with 9+ years of progressive manufacturing experience, specializing in lean operations and team leadership. I’ve reduced production costs by 17% while increasing output quality by establishing cross-functional teams and standardizing processes. Known for building high-performing teams that consistently exceed production targets even during supply chain disruptions.

PROFESSIONAL EXPERIENCE

SENIOR PRODUCTION MANAGER | Midwest Manufacturing Solutions | Chicago, IL | 04/2020 – Present

- Lead daily operations for 3 production lines with 45+ team members, achieving 99.3% on-time delivery despite pandemic disruptions

- Cut material waste by 23% through implementation of modified kanban system and operator training program

- Reduced production cycle time from 37 minutes to 29 minutes by eliminating non-value-added steps and reorganizing workstations

- Developed and launched new production scheduling system that improved machine utilization by 14%

- Collaborate with R&D to transition 6 new products from prototype to full production, beating timeline targets by avg. 2 weeks

PRODUCTION MANAGER | Precision Components Inc. | Milwaukee, WI | 06/2017 – 03/2020

- Managed team of 28 production workers across 2 shifts, reducing overtime hours by 31% through improved scheduling

- Led kaizen events resulting in $378K annual savings through process improvements and setup time reduction

- Implemented TPM program that increased equipment availability from 82% to 91% in 18 months

- Upgraded quality control procedures, cutting customer returns by 47% and earning supplier quality award

- Partnered with HR to develop training matrix and career pathing program that reduced turnover from 27% to 12%

PRODUCTION SUPERVISOR | Alltech Manufacturing | Chicago, IL | 08/2014 – 05/2017

- Supervised daily operations of assembly line with 15 operators, consistently meeting or exceeding production targets

- Spearheaded 5S implementation that improved workspace organization and reduced search time by 65%

- Trained and mentored 3 team leads who were later promoted to supervisory roles

- Collaborated with maintenance to reduce unplanned downtime by 28% through preventive maintenance program

EDUCATION & CERTIFICATIONS

Bachelor of Science, Industrial Engineering – Illinois Institute of Technology, 2014

Certifications:

- Lean Six Sigma Black Belt – American Society for Quality (2019)

- Certified Production and Inventory Management (CPIM) – APICS (2018)

- Total Productive Maintenance Practitioner – Manufacturing Excellence Institute (2016)

SKILLS

- Production Planning & Scheduling

- Lean Manufacturing & Continuous Improvement

- Team Leadership & Employee Development

- Quality Control Systems (ISO 9001)

- ERP Systems (SAP, Oracle)

- Cost Reduction Strategies

- KPI Development & Performance Analysis

- Supply Chain Management

- Process Documentation & Standardization

- Root Cause Analysis & Problem Solving

ADDITIONAL INFORMATION

Committee Member, Chicago Manufacturing Leadership Council (2019-Present)

Fluent in English and Spanish

Willing to travel up to 20% for multi-site responsibilities

How to Write a Production Manager Resume

Introduction

In manufacturing and operations, your resume isn't just a document—it's the blueprint that showcases your ability to manage complex production systems. As someone who's reviewed thousands of Production Manager resumes, I can tell you that hiring managers spend about 7.4 seconds on their initial scan. That's barely enough time to determine if you're worth a deeper look! A well-crafted resume doesn't just list jobs; it demonstrates your expertise in production planning, quality control, team leadership, and cost reduction—the core competencies every successful Production Manager needs.

Resume Structure and Format

Keep your resume clean and organized—just like you'd keep your production floor. Aim for 1-2 pages (though folks with 15+ years of experience might stretch to 2 full pages). Use a simple, readable font like Arial or Calibri at 10-12pt.

- Create clear sections with bold headings (Contact Info, Summary, Experience, Skills, Education)

- Use bullet points rather than paragraphs for easier scanning

- Include white space to prevent a cluttered appearance

- Save as a PDF unless specifically asked for a different format (maintains formatting across devices)

Profile/Summary Section

Your summary is like the spec sheet for a product—it needs to quickly communicate your value. In 3-5 lines, highlight your years of experience, production specialties, and biggest achievements.

Tailor your summary to the specific job! Review the posting and mirror key requirements. If they want someone with Lean Six Sigma experience who's reduced costs, highlight exactly that in your summary.

Example: "Production Manager with 8+ years overseeing multi-shift operations in food manufacturing. Reduced production costs by 17% while maintaining 99.3% quality standards. Experienced in JIT inventory systems and team leadership across 45+ direct reports."

Professional Experience

This is where you prove you can handle the job. For each position:

- Start with company name, location, your title, and dates (month/year)

- Include a brief description of the operation (size, volume, products)

- List 4-6 bullet points focusing on accomplishments, not just duties

- Begin bullets with strong action verbs: Implemented, Reduced, Increased, Streamlined

- Quantify results whenever possible ($ saved, % improved, units produced)

Weak: "Responsible for production scheduling"

Strong: "Redesigned production scheduling process, cutting lead times by 31% and reducing overtime costs by $247,000 annually"

Education and Certifications

List your degrees in reverse chronological order. For Production Managers, relevant certifications often carry significant weight—sometimes even more than degrees. Highlight certifications like:

- Lean Six Sigma (especially Green/Black Belt)

- PMP (Project Management Professional)

- APICS CPIM (Certified in Production and Inventory Management)

- TQM (Total Quality Management) certifications

Keywords and ATS Tips

Most companies use Applicant Tracking Systems that scan resumes before human eyes ever see them. These bots look for specific keywords related to the job. For Production Manager positions, make sure you include:

- Production planning/scheduling

- Inventory management

- KPIs/metrics tracking

- Quality control/assurance

- Lean manufacturing

- Supply chain management

- Staff training/development

Industry-specific Terms

Sprinkle your resume with relevant terminology that shows you speak the language of manufacturing. Terms like JIT (Just-In-Time), OEE (Overall Equipment Effectiveness), CAPA (Corrective and Preventive Action), kanban, SMED, and TPM (Total Productive Maintenance) signal to hiring managers that you understand production environments.

Common Mistakes to Avoid

- Being vague about production volumes or team size

- Focusing solely on responsibilities rather than achievements

- Omitting metrics and quantifiable results

- Listing every single job duty instead of highlighting key accomplishments

- Using manufacturing jargon without demonstrating results (Tom in HR might not know what SMED means!)

Before/After Example

Before: "Managed production team and scheduled daily operations."

After: "Led 37-person production team across 3 shifts, implementing visual management boards that increased daily throughput by 24% and reduced changeover times from 45 to 17 minutes."

The difference? The second example proves you deliver results—and that's exactly what hiring managers want to see. Your resume should make them think, "This person could solve our production problems starting day one."

Related Resume Examples

Soft skills for your Production Manager resume

- Cross-functional team leadership (managed teams of 8-12 across production, quality, and maintenance)

- Conflict resolution in high-pressure manufacturing environments

- Change management during production transitions (my team called me “the buffer” during our ERP implementation)

- Strategic resource allocation when facing competing priorities

- Stakeholder communication – translating technical issues for non-technical audiences

- Mentoring and developing shift supervisors and line leads

Hard skills for your Production Manager resume

- Lean Manufacturing & Six Sigma Green Belt certification

- Production scheduling using Epicor ERP and MS Project

- Quality control procedures (SPC, FMEA, 8D problem solving)

- Supply chain management and JIT inventory systems

- CAD/CAM software familiarity (SolidWorks basics)

- Root cause analysis techniques and Kaizen implementation

- ISO 9001:2015 standards and compliance procedures

- Cost estimation and production budgeting (5% under budget for FY22)

- MRP systems and production planning optimization