Plant Operator Resume examples & templates

Copyable Plant Operator Resume examples

While air traffic controllers orchestrate the skies, plant operators conduct a symphony of machinery and processes on the ground. Behind the scenes at power plants, manufacturing facilities, and water treatment centers, these professionals keep the systems running that most people take for granted. Unlike the software engineer who might work remotely in pajamas, plant operators are hands-on specialists who troubleshoot equipment issues, monitor control systems, and make split-second decisions that can impact thousands of homes and businesses. According to the Bureau of Labor Statistics, the median annual wage for power plant operators reached $89,090 in 2022—higher than the national average despite many positions requiring just a high school diploma and on-the-job training.

The field is changing fast. Automation hasn't replaced operators (as some predicted), but it has transformed their work. Many facilities now use digital twins—virtual replicas of physical systems—to simulate operations before implementing changes. Plant operators increasingly need both mechanical aptitude and digital literacy, a combination that's created a skills gap at many facilities. With aging infrastructure needing replacement and renewable energy systems expanding, the next generation of plant operators will likely split their time between monitoring screens and getting their hands dirty with essential equipment.

Junior Plant Operator Resume Example

Trevor Daniels

Phone: (503) 792-4561 • Email: trevor.daniels@gmail.com • LinkedIn: linkedin.com/in/trevordaniels

Portland, OR 97217

Entry-level Plant Operator with hands-on experience in manufacturing environments. Quick learner with strong mechanical aptitude and commitment to safety protocols. Skilled in basic equipment maintenance, monitoring production processes, and troubleshooting minor operational issues. Looking to grow my skills with a company that values reliability and attention to detail.

EXPERIENCE

Junior Plant Operator

Pacific Northwest Manufacturing • Portland, OR • January 2022 – Present

- Monitor and operate production equipment including mixers, pumps, and packaging machinery according to established procedures

- Perform quality checks at various stages of production process, reducing defect rate by 7%

- Record production data and maintain accurate logs of equipment performance and maintenance

- Assist with basic preventative maintenance tasks under supervision of senior operators

- Participate in monthly safety meetings and maintain 100% compliance with PPE requirements

Production Assistant

Riverdale Manufacturing • Vancouver, WA • May 2021 – December 2021

- Supported production team by preparing materials and components for assembly line

- Conducted visual inspections of finished products to ensure quality standards were met

- Learned basic operation of manufacturing equipment through on-the-job training

- Maintained clean and organized work environment to improve efficiency and safety

Warehouse Associate (Part-time)

Portland Supply Co. • Portland, OR • June 2020 – April 2021

- Received, stored, and distributed materials and products within warehouse facility

- Operated forklift to move palletized goods between storage areas

- Performed inventory counts and reconciled discrepancies

EDUCATION

Associate of Applied Science, Industrial Technology

Portland Community College • Portland, OR • Graduated May 2021

CERTIFICATIONS

- OSHA 10-Hour General Industry Safety (2021)

- Forklift Operator Certification (2020, renewed 2023)

- Basic First Aid & CPR Certification (2022)

SKILLS

- Equipment Operation & Monitoring

- Preventative Maintenance

- Process Control

- Quality Assurance

- Troubleshooting

- Safety Procedures

- Data Recording & Reporting

- Mechanical Aptitude

- Attention to Detail

- Team Collaboration

Mid-level Plant Operator Resume Example

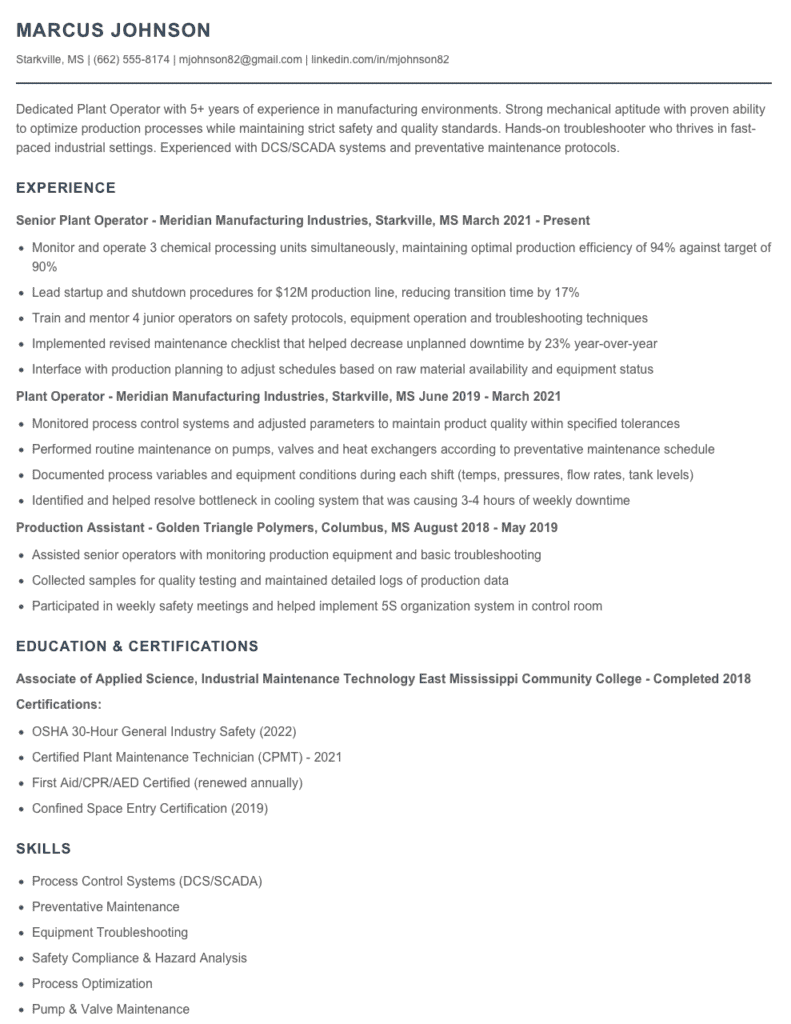

MARCUS JOHNSON

Starkville, MS | (662) 555-8174 | mjohnson82@gmail.com | linkedin.com/in/mjohnson82

Dedicated Plant Operator with 5+ years of experience in manufacturing environments. Strong mechanical aptitude with proven ability to optimize production processes while maintaining strict safety and quality standards. Hands-on troubleshooter who thrives in fast-paced industrial settings. Experienced with DCS/SCADA systems and preventative maintenance protocols.

EXPERIENCE

Senior Plant Operator – Meridian Manufacturing Industries, Starkville, MS

March 2021 – Present

- Monitor and operate 3 chemical processing units simultaneously, maintaining optimal production efficiency of 94% against target of 90%

- Lead startup and shutdown procedures for $12M production line, reducing transition time by 17%

- Train and mentor 4 junior operators on safety protocols, equipment operation and troubleshooting techniques

- Implemented revised maintenance checklist that helped decrease unplanned downtime by 23% year-over-year

- Interface with production planning to adjust schedules based on raw material availability and equipment status

Plant Operator – Meridian Manufacturing Industries, Starkville, MS

June 2019 – March 2021

- Monitored process control systems and adjusted parameters to maintain product quality within specified tolerances

- Performed routine maintenance on pumps, valves and heat exchangers according to preventative maintenance schedule

- Documented process variables and equipment conditions during each shift (temps, pressures, flow rates, tank levels)

- Identified and helped resolve bottleneck in cooling system that was causing 3-4 hours of weekly downtime

Production Assistant – Golden Triangle Polymers, Columbus, MS

August 2018 – May 2019

- Assisted senior operators with monitoring production equipment and basic troubleshooting

- Collected samples for quality testing and maintained detailed logs of production data

- Participated in weekly safety meetings and helped implement 5S organization system in control room

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Industrial Maintenance Technology

East Mississippi Community College – Completed 2018

Certifications:

- OSHA 30-Hour General Industry Safety (2022)

- Certified Plant Maintenance Technician (CPMT) – 2021

- First Aid/CPR/AED Certified (renewed annually)

- Confined Space Entry Certification (2019)

SKILLS

- Process Control Systems (DCS/SCADA)

- Preventative Maintenance

- Equipment Troubleshooting

- Safety Compliance & Hazard Analysis

- Process Optimization

- Pump & Valve Maintenance

- Documentation & Reporting

- Blueprint Reading

- Team Leadership

- Lock-Out/Tag-Out Procedures

ADDITIONAL INFORMATION

Available for rotating shifts and weekend work. Familiar with ISO 9001 quality management principles. Completed in-house forklift certification (still valid through 2024).

Senior / Experienced Plant Operator Resume Example

Mark Jennings

Phoenix, AZ • (480) 555-8722 • m.jennings85@email.com • linkedin.com/in/markjennings85

Dedicated Plant Operator with 12+ years of experience in industrial manufacturing environments. Expertise in monitoring equipment performance, troubleshooting complex mechanical issues, and implementing preventive maintenance protocols that reduced downtime by 31% at current facility. Proven track record of maintaining safety standards while maximizing production efficiency and training junior operators.

EXPERIENCE

Senior Plant Operator | Southwest Processing Solutions | Phoenix, AZ | 2018 – Present

- Oversee daily operations of a 175,000 sq. ft. chemical processing facility, managing equipment calibration and maintenance scheduling for 27 production units

- Developed and implemented new equipment monitoring protocols that reduced unplanned downtime by 31% and saved approximately $437K in annual maintenance costs

- Supervise team of 8 junior operators, providing technical guidance and safety training while ensuring compliance with EPA and OSHA regulations

- Collaborate with engineering team to identify and resolve production bottlenecks, improving monthly output by 22% without additional resource allocation

- Created comprehensive digital documentation system that improved shift handovers and reduced process errors by 47%

Plant Operator II | Meridian Manufacturing | Tucson, AZ | 2014 – 2018

- Monitored and operated industrial equipment including centrifugal pumps, boilers, and filtration systems in 24/7 production environment

- Performed routine maintenance and troubleshooting on process equipment, reducing average repair time from 4.5 hours to 2.7 hours

- Managed chemical inventories and coordinated with suppliers to prevent production delays (we never ran out on my watch!)

- Identified critical valve failure patterns that led to redesign of cooling system, preventing potential $250K catastrophic equipment failure

Plant Operator I | Desert Valley Processing | Mesa, AZ | 2011 – 2014

- Operated control systems for water treatment facility serving 3 manufacturing plants

- Collected and tested water samples, maintaining precise records of chemical composition and quality metrics

- Assisted with equipment maintenance and cleaning procedures according to established schedules

- Participated in safety committee that achieved 847 consecutive days without a reportable incident

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Industrial Technology

Maricopa Community College | Phoenix, AZ | 2011

Certifications:

- Certified Plant Maintenance Technician (CPMT) – 2016, renewed 2021

- OSHA 30-Hour General Industry Safety Certification – 2019

- Hazardous Materials Handling Certification – 2017

- Confined Space Entry Certification – 2015

- First Aid/CPR/AED Certification – Current

SKILLS

- Process Control Systems (DCS, SCADA)

- Preventive & Predictive Maintenance

- Equipment Troubleshooting

- Quality Control Procedures

- Safety Compliance (OSHA, EPA)

- Chemical Handling & Storage

- Boiler & Pressure Vessel Operation

- Process Optimization

- Team Leadership & Training

- Emergency Response Protocols

How to Write a Plant Operator Resume

Introduction

Writing a standout resume for a Plant Operator position isn't just about listing your previous jobs—it's about showcasing your technical expertise, safety consciousness, and problem-solving abilities. Having reviewed hundreds of plant operator resumes over the years, I've noticed that the ones that get interviews share certain qualities: they're concrete, specific, and clearly demonstrate both technical skills and reliability. Your resume is your first chance to prove you can handle the responsibilities of monitoring equipment, maintaining production schedules, and responding to emergencies.

Resume Structure and Format

Keep your plant operator resume clean and readable—just like a well-maintained control panel. Aim for 1-2 pages depending on your experience level. Avoid fancy fonts or graphics that might confuse applicant tracking systems (ATS).

- Use a clean, professional font like Arial or Calibri in 10-12pt size

- Include clear section headings (Experience, Skills, Certifications)

- Use bullet points rather than paragraphs for work experience

- Left-align text for better readability

- Save your resume as a PDF unless otherwise specified

Profile/Summary Section

Start with a brief (3-4 sentence) summary that captures your experience level, key qualifications, and standout achievements. This section should be tailored to each job application.

For example: "Plant Operator with 6+ years of experience managing boiler systems and water treatment processes. Certified in HVAC operations and hazardous materials handling. Reduced downtime by 17% through preventative maintenance initiatives while maintaining perfect safety record."

Write your summary last! It's much easier to create a strong opening after you've completed the rest of your resume and can extract the highlights.

Professional Experience

This is where the rubber meets the road. For each position, include:

- Company name, location, and dates of employment

- Your official job title

- 4-6 bullet points highlighting responsibilities and accomplishments

Focus on measurable results whenever possible. Instead of saying "Monitored equipment," try "Monitored 12 production units across 3 production lines, identifying maintenance needs that prevented 5 potential failures in 2022."

Education and Certifications

Plant operation often requires specific training and certifications. List these prominently, especially if they match requirements in the job posting:

- Technical degrees or diplomas

- Boiler operator licenses

- HVAC certifications

- Water/wastewater treatment certifications

- OSHA safety training

- Equipment-specific training (like Siemens control systems)

Include completion dates and renewal information if applicable.

Keywords and ATS Tips

Many employers use applicant tracking systems to filter resumes before a human ever sees them. To pass this first hurdle:

- Study the job posting and mirror key terms (if they say "monitor system parameters," use those exact words)

- Include industry-standard abbreviations both spelled out and as acronyms (e.g., "Preventative Maintenance (PM)")

- Avoid tables, headers/footers, and text boxes that can confuse ATS software

- Name your file clearly: "JohnSmith_PlantOperator_Resume.pdf"

Industry-specific Terms

Pepper your resume with relevant terminology that shows you speak the language of plant operations:

- Equipment names (centrifugal pumps, boilers, turbines)

- Control systems (SCADA, DCS, PLC)

- Safety protocols (LOTO, confined space entry)

- Maintenance types (preventative, predictive, corrective)

- Monitoring parameters (pressure, temperature, flow rates)

Common Mistakes to Avoid

- Being too vague about technical responsibilities

- Focusing solely on duties rather than accomplishments

- Omitting metrics (efficiency rates, downtime reductions)

- Neglecting to mention safety record or compliance experience

- Using technical jargon without demonstrating understanding

Before/After Example

Before: "Responsible for monitoring equipment and making adjustments as needed."

After: "Monitored 8 ammonia refrigeration compressors on 12-hour shifts, making real-time adjustments that maintained optimal temperature ranges within ±1.5°F, resulting in 9% energy savings and zero product loss during 2023."

Remember, your resume should tell the story of not just what you did, but how well you did it. Plant operation requires attention to detail, technical knowledge, and quick thinking—make sure these qualities shine through in your application!

Related Resume Examples

Soft skills for your Plant Operator resume

- Collaborative troubleshooting – able to work with maintenance techs and engineers to diagnose equipment issues before they cause downtime

- Shift handover communication – skilled at conveying critical operational status and pending tasks to incoming operators

- Safety mentorship for newer team members (helped 4 junior operators earn safety certifications)

- Stress management during emergency shutdowns and equipment failures

- Cross-functional coordination between production, quality control, and maintenance departments

- Adaptability to changing production schedules and last-minute priority shifts

Hard skills for your Plant Operator resume

- SCADA system monitoring and troubleshooting

- Distillation column operation (packed and trayed)

- PLC programming – Allen Bradley RSLogix 5000

- API 570 Piping Inspector certification

- Heat exchanger maintenance and cleaning procedures

- Centrifugal pump repair (Flowserve and Grundfos)

- SAP Plant Maintenance module

- Lock-out/Tag-out (LOTO) procedures

- Waste treatment system operation (pH neutralization)