Manufacturing Technician Resume examples & templates

Copyable Manufacturing Technician Resume examples

The hum of machinery fills the air as Elaine checks her digital tablet, confirming the production specs for today's run. It's 6:42 AM and she's already completed her equipment safety inspection, calibrated three precision tools and briefed the incoming shift on yesterday's output variance. As a Manufacturing Technician at Meridian Components, her morning routine blends technical expertise with practical problem-solving—adjusting tolerances on CNC machines one minute, troubleshooting an unexpected materials issue the next. The coffee in her travel mug is still warm, but she likely won't finish it until her 9:30 break.

Manufacturing technicians like Elaine represent the evolving backbone of American production floors. With the integration of IoT sensors and predictive maintenance systems, today's techs are as likely to analyze performance data as they are to replace worn components. The field has seen a 17.3% increase in specialized certification requirements since 2019, reflecting the growing technical complexity of modern manufacturing environments. As factories continue their digital transformation journey, technicians who can bridge the gap between traditional mechanical systems and emerging smart technologies will find themselves increasingly valuable—not just maintaining production lines, but actively improving them.

Junior Manufacturing Technician Resume Example

Tyler Jenkins

Manufacturing Technician | Akron, OH | (330) 555-8216 | tyler.jenkins@email.com | linkedin.com/in/tylerjenkins

Detail-oriented Manufacturing Technician with 1+ year experience in production environments. Quick learner with hands-on experience operating and maintaining manufacturing equipment in food processing settings. Associate’s degree in Manufacturing Technology with focus on quality control procedures and preventive maintenance.

EXPERIENCE

Manufacturing Technician | Midwest Food Solutions | Akron, OH | June 2022 – Present

- Monitor and operate 4 production lines for frozen food products, maintaining 97% uptime across assigned equipment

- Perform daily equipment inspections and basic maintenance on conveyor systems, reducing unplanned downtime by 14%

- Document production metrics and equipment issues in SAP system for 12+ batches per shift

- Collaborate with maintenance team to troubleshoot equipment malfunctions, sometimes staying late to ensure production quotas are met

- Maintain clean work environment following GMP and food safety protocols

Production Assistant (Part-time) | Cleveland Packaging Co. | Cleveland, OH | Sept 2021 – May 2022

- Assisted with packaging operations while completing final year of associate’s degree

- Prepared materials for production runs and organized inventory of packaging supplies

- Helped implement new labeling system that cut mislabeling errors from 3% to under 1%

Manufacturing Intern | Precision Parts Inc. | Canton, OH | May – August 2021

- Shadowed technicians across 3 departments to learn manufacturing processes

- Collected quality control data and entered findings into Excel spreadsheets

- Participated in weekly safety meetings and completed OSHA-10 certification

EDUCATION

Associate of Applied Science, Manufacturing Technology | May 2022

Stark State College, North Canton, OH

GPA: 3.7/4.0

Certifications:

- OSHA-10 Safety Certification (2021)

- Basic Maintenance Technician Certification (2022)

- Food Handler’s Certification (2022)

SKILLS

- Equipment Operation: Conveyor systems, packaging equipment, mixers, industrial ovens

- Quality Control: Visual inspection, basic testing procedures, documentation

- Maintenance: Preventive maintenance, basic troubleshooting, parts replacement

- Computer Skills: Microsoft Office, SAP (basic), inventory management systems

- Health & Safety: GMP, HACCP awareness, lockout/tagout procedures

- Technical: Reading blueprints, following SOPs, mechanical aptitude

- Soft Skills: Team collaboration, attention to detail, problem-solving

ADDITIONAL INFORMATION

Willing to work all shifts including weekends and holidays as needed. Valid driver’s license with reliable transportation.

Mid-level Manufacturing Technician Resume Example

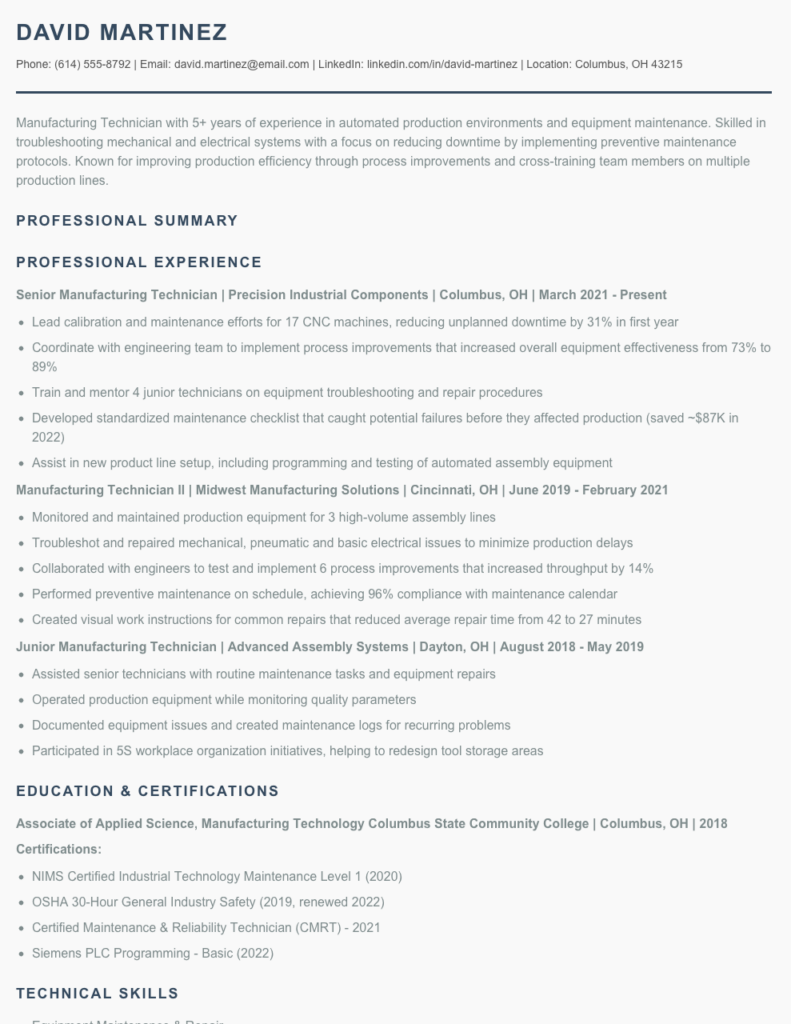

David Martinez

(614) 555-8792 | david.martinez@email.com | linkedin.com/in/david-martinez | Columbus, OH 43215

PROFESSIONAL SUMMARY

Manufacturing Technician with 5+ years of experience in automated production environments and equipment maintenance. Skilled in troubleshooting mechanical and electrical systems with a focus on reducing downtime by implementing preventive maintenance protocols. Known for improving production efficiency through process improvements and cross-training team members on multiple production lines.

PROFESSIONAL EXPERIENCE

Senior Manufacturing Technician | Precision Industrial Components | Columbus, OH | March 2021 – Present

- Lead calibration and maintenance efforts for 17 CNC machines, reducing unplanned downtime by 31% in first year

- Coordinate with engineering team to implement process improvements that increased overall equipment effectiveness from 73% to 89%

- Train and mentor 4 junior technicians on equipment troubleshooting and repair procedures

- Developed standardized maintenance checklist that caught potential failures before they affected production (saved ~$87K in 2022)

- Assist in new product line setup, including programming and testing of automated assembly equipment

Manufacturing Technician II | Midwest Manufacturing Solutions | Cincinnati, OH | June 2019 – February 2021

- Monitored and maintained production equipment for 3 high-volume assembly lines

- Troubleshot and repaired mechanical, pneumatic and basic electrical issues to minimize production delays

- Collaborated with engineers to test and implement 6 process improvements that increased throughput by 14%

- Performed preventive maintenance on schedule, achieving 96% compliance with maintenance calendar

- Created visual work instructions for common repairs that reduced average repair time from 42 to 27 minutes

Junior Manufacturing Technician | Advanced Assembly Systems | Dayton, OH | August 2018 – May 2019

- Assisted senior technicians with routine maintenance tasks and equipment repairs

- Operated production equipment while monitoring quality parameters

- Documented equipment issues and created maintenance logs for recurring problems

- Participated in 5S workplace organization initiatives, helping to redesign tool storage areas

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Manufacturing Technology

Columbus State Community College | Columbus, OH | 2018

Certifications:

- NIMS Certified Industrial Technology Maintenance Level 1 (2020)

- OSHA 30-Hour General Industry Safety (2019, renewed 2022)

- Certified Maintenance & Reliability Technician (CMRT) – 2021

- Siemens PLC Programming – Basic (2022)

TECHNICAL SKILLS

- Equipment Maintenance & Repair

- Preventive Maintenance Planning

- Hydraulic & Pneumatic Systems

- PLC Monitoring & Basic Programming

- Technical Documentation

- Mechanical Assembly/Disassembly

- Quality Control Procedures

- Root Cause Analysis

- Lean Manufacturing Principles

- MRP Systems (SAP)

ADDITIONAL INFORMATION

Volunteer instructor for weekend “Intro to Manufacturing” workshops at local high school (2021-Present)

Fluent in English and Spanish (conversational)

Senior / Experienced Manufacturing Technician Resume Example

Marcus Rodriguez

Sarasota, FL 34231 | (941) 555-8247 | m.rodriguez@emailpro.net | linkedin.com/in/marcusrodriguez

Manufacturing Technician with 9+ years of experience in medical device and aerospace manufacturing environments. Skilled in CNC operation, precision measurement, and lean manufacturing principles. Known for troubleshooting complex equipment issues that reduced downtime by 31% at Precision Aero Components. Currently pursuing Six Sigma Green Belt certification to complement hands-on expertise.

PROFESSIONAL EXPERIENCE

Senior Manufacturing Technician | MediTech Devices, Inc. | Sarasota, FL | March 2020 – Present

- Lead a team of 6 technicians in Class II medical device manufacturing, ensuring compliance with FDA regulations and ISO 13485 standards

- Operate and program 5-axis CNC machines to produce titanium implant components with tolerances of ±0.0005 inches

- Created standardized work instructions that cut new employee training time from 4 weeks to 17 days

- Collaborate with engineering to implement process improvements, resulting in 23% reduction in scrap rate

- Perform preventive maintenance on manufacturing equipment worth over $3.2M, extending useful life by approximately 3 years

Manufacturing Technician II | Precision Aero Components | Tampa, FL | June 2017 – March 2020

- Operated CNC mills, lathes, and EDM equipment to manufacture critical aerospace components

- Identified and fixed recurring equipment fault that had caused 18 hours of monthly downtime (nobody had figured it out for almost a year!)

- Used CMM and other precision measurement equipment to verify parts met engineering specifications

- Participated in kaizen events that improved production flow, reducing WIP by 40%

Manufacturing Technician | Global Electronics Manufacturing | Bradenton, FL | August 2014 – June 2017

- Set up and operated SMT equipment for PCB assembly and soldering

- Performed quality inspections using microscopes and testing equipment

- Maintained production records and tracked key performance metrics

- Cross-trained on 7 different workstations to provide coverage during staff shortages

EDUCATION & CERTIFICATIONS

Associate of Science in Manufacturing Technology | State College of Florida | 2014

Six Sigma Green Belt Certification | ASQ | In Progress (expected completion December 2023)

CNC Programming and Operation Certificate | Manatee Technical College | 2016

OSHA 30-Hour General Industry Safety Certification | 2019

TECHNICAL SKILLS

- CNC Programming & Operation (Haas, Mazak, Fanuc)

- Precision Measurement (CMM, micrometers, calipers, gauges)

- GD&T interpretation

- Preventive maintenance

- Technical documentation

- Lean manufacturing principles

- 5S workplace organization

- SolidWorks (basic)

- Quality inspection techniques

- Machining troubleshooting

ADDITIONAL INFORMATION

Available for occasional weekend overtime and emergency maintenance calls. Fluent in English and conversational Spanish. Member of Society of Manufacturing Engineers since 2018.

How to Write a Manufacturing Technician Resume

Introduction

Landing that manufacturing technician job means getting past the first hurdle—your resume. I've reviewed thousands of manufacturing resumes over the years, and the difference between those that get interviews and those that don't often comes down to a few key elements. Manufacturing employers are looking for technical competence, attention to detail, and reliability—qualities that should be woven throughout your resume, not just stated outright. Let's break down how to create a resume that showcases your manufacturing skills and experience in a way that catches a hiring manager's eye.

Resume Structure and Format

Keep your manufacturing technician resume clean and organized—just like your workstation should be! A cluttered resume suggests a cluttered mind, which doesn't inspire confidence in someone who might be handling precision equipment.

- Stick to 1-2 pages (one page for less than 5 years experience)

- Use a simple, readable font like Arial or Calibri in 10-12pt size

- Include clear section headings with consistent formatting

- Use bullet points rather than paragraphs for work experience

- Save as a PDF unless specifically asked for another format (preserves formatting)

Profile/Summary Section

Your summary should be short and punchy—think of it as your 30-second elevator pitch. For manufacturing technicians, emphasize your years of experience, specialized equipment knowledge, and standout qualifications.

Example: "Manufacturing Technician with 4+ years operating CNC equipment in high-volume automotive parts production. Skilled in preventative maintenance, quality inspection, and lean manufacturing practices. Certified in OSHA safety protocols with track record of 873 consecutive days without safety incidents."

Pro Tip: Tailor your summary for each job application. If the posting emphasizes quality control, highlight your SPC knowledge or Six Sigma training. If it's more about production efficiency, mention your experience with continuous improvement or specific productivity metrics you've achieved.

Professional Experience

This is where you prove you can do the job. Manufacturing managers want specifics—machines you've operated, processes you've improved, problems you've solved. Generic statements won't cut it on the production floor.

- Start each bullet with a strong action verb (operated, maintained, calibrated)

- Include specific equipment models you've used (Haas VF-2 CNC, Fanuc Robotics)

- Quantify your achievements (reduced setup time by 17%, maintained 99.3% quality rating)

- Mention relevant manufacturing methodologies (5S, TPM, Kaizen)

- Include troubleshooting and maintenance experience

Education and Certifications

Many manufacturing technician roles value certifications as much as formal education. List your most relevant qualifications first, regardless of when you earned them.

- Technical diplomas or degrees (Associate's in Manufacturing Technology, etc.)

- Equipment-specific certifications (CNC Programming, Welding Certification)

- Safety certifications (OSHA 10/30, Forklift Operator)

- Quality-related certifications (Six Sigma, ISO 9001 Familiarity)

- Relevant continuing education courses

Keywords and ATS Tips

Most manufacturing companies use Applicant Tracking Systems to screen resumes before a human ever sees them. Your resume needs to include the right keywords to make it through this digital gatekeeper.

- Study the job description and mirror key terms (if they say "preventative maintenance," don't call it "preventive maintenance")

- Include specific equipment names mentioned in the posting

- Mention industry standards relevant to the position (ISO, GMP, etc.)

- Avoid images, headers/footers, and tables that ATS systems struggle to read

Industry-specific Terms

Showing familiarity with manufacturing terminology demonstrates you know what you're talking about. Some key terms to consider (where relevant to your experience):

- Manufacturing processes: CNC, injection molding, welding, assembly

- Quality control: SPC, gauging, CMM, GD&T, first article inspection

- Improvement methodologies: Lean, Six Sigma, 5S, Kaizen

- Documentation: SOPs, work instructions, batch records

- Maintenance: PM, TPM, predictive maintenance

Common Mistakes to Avoid

- Being vague about technical skills (list specific machines and processes)

- Focusing only on duties rather than achievements

- Neglecting to mention safety awareness and compliance

- Using too much technical jargon without demonstrating practical application

- Forgetting to proofread (spelling errors suggest lack of attention to detail—a killer in manufacturing)

Remember, your resume is your ticket to the interview. Make every word count, focus on relevant skills, and show how you've contributed to efficiency, quality, and safety in your previous roles. Good luck on the manufacturing floor!

Related Resume Examples

Soft skills for your Manufacturing Technician resume

- Cross-functional team collaboration – comfortable working with engineers, quality control, and operations staff during complex production transitions

- Troubleshooting communication – able to clearly explain technical problems to both technical and non-technical team members

- Shift flexibility – mentally resilient when switching between day/night shifts while maintaining consistent quality standards

- Mentorship capabilities – experience training junior technicians on equipment safety protocols and preventative maintenance procedures

- Process improvement mindset – proactively identifies inefficiencies in manufacturing workflows and suggests practical solutions

- Stress management under tight production deadlines – maintains focus and precision even during high-pressure situations

Hard skills for your Manufacturing Technician resume

- GMP & FDA compliance documentation (ISO 9001:2015)

- PLC troubleshooting for Allen-Bradley and Siemens systems

- SPC & statistical analysis using Minitab 19

- Precision measurement with digital micrometers (±0.0005″)

- CMMS maintenance scheduling (Maximo 7.6)

- CNC machine operation (Haas VF-2SS)

- Equipment calibration & validation

- 5S and lean manufacturing techniques

- SAP inventory management