Maintenance Technician Resume examples & templates

Copyable Maintenance Technician Resume examples

From the maintenance crews who kept ancient Roman aqueducts flowing to the factory mechanics of the Industrial Revolution, the role of maintenance technicians has been crucial to human progress for centuries. These skilled professionals have adapted alongside technological advancement—transforming from basic repairmen to multi-skilled technicians proficient in mechanical systems, electronics, hydraulics, and increasingly, computerized maintenance management systems. Today's maintenance techs are the unsung heroes who keep our modern world functioning, whether in manufacturing plants, hospitals, office buildings, or apartment complexes.

The field is experiencing significant growth, with the Bureau of Labor Statistics projecting a 17.6% increase in industrial machinery mechanic positions through 2031—much faster than the average for all occupations. This surge comes as facilities embrace predictive maintenance strategies, where techs use IoT sensors and data analytics to prevent breakdowns before they occur. Meanwhile, the skills gap continues to widen; a recent industry survey found that 62% of facility managers struggle to find qualified maintenance personnel. For those with the right mix of technical aptitude and problem-solving skills, maintenance technology offers stable employment, competitive wages (median annual salary of $54,920), and the satisfaction of being the person everyone counts on when systems fail.

Junior Maintenance Technician Resume Example

MARCUS RODRIGUEZ

Denver, CO 80219 • (720) 555-8142 • marcusrod93@email.com • linkedin.com/in/marcusrodriguez

Maintenance Technician with hands-on experience in equipment repair and preventive maintenance. Skilled in troubleshooting mechanical and electrical systems with focus on minimizing downtime. Quick learner with strong problem-solving skills and commitment to workplace safety. Seeking to grow technical expertise while supporting efficient facility operations.

EXPERIENCE

Maintenance Technician | Rocky Mountain Manufacturing | Denver, CO | August 2022 – Present

- Perform preventive maintenance on production equipment resulting in 17% reduction in unplanned downtime

- Troubleshoot and repair mechanical, hydraulic, and basic electrical systems across 3 production lines

- Document all maintenance activities in company CMMS system, improving repair history tracking

- Respond to emergency maintenance calls, achieving average response time of 12 minutes

- Help implement new PM schedule that extended average equipment life by 8 months

Maintenance Assistant (Part-time) | Westview Apartments | Denver, CO | May 2021 – August 2022

- Assisted lead technician with repairs in 120-unit apartment complex

- Completed basic plumbing repairs including fixing leaks, unclogging drains, and replacing fixtures

- Performed routine HVAC maintenance such as filter changes and condenser cleaning

- Helped diagnose and repair common appliance issues in resident units

Warehouse Associate | Precision Supply Co. | Aurora, CO | June 2020 – May 2021

- Maintained warehouse equipment including pallet jacks, forklifts, and conveyor systems

- Assisted maintenance team with equipment repairs during high-volume periods

- Identified recurring mechanical issues with sorting equipment, saving $4,300 in potential repair costs

EDUCATION

Associate of Applied Science, Industrial Maintenance Technology

Front Range Community College | Westminster, CO | Graduated May 2022

Technical Certifications:

- OSHA 10-Hour General Industry Safety (2021)

- EPA 608 Type II Certification (2022)

- Forklift Operator Certification (2020, renewed 2023)

SKILLS

- Mechanical repair & troubleshooting

- Preventive maintenance

- Basic electrical systems

- Hydraulic & pneumatic systems

- Blueprint reading

- Hand & power tools

- CMMS software

- Welding (basic MIG)

- Plumbing repairs

- Equipment lubrication

- Inventory management

ADDITIONAL INFORMATION

Available for rotating shifts and emergency call-outs • Clean driving record • Bilingual: English/Spanish

Mid-level Maintenance Technician Resume Example

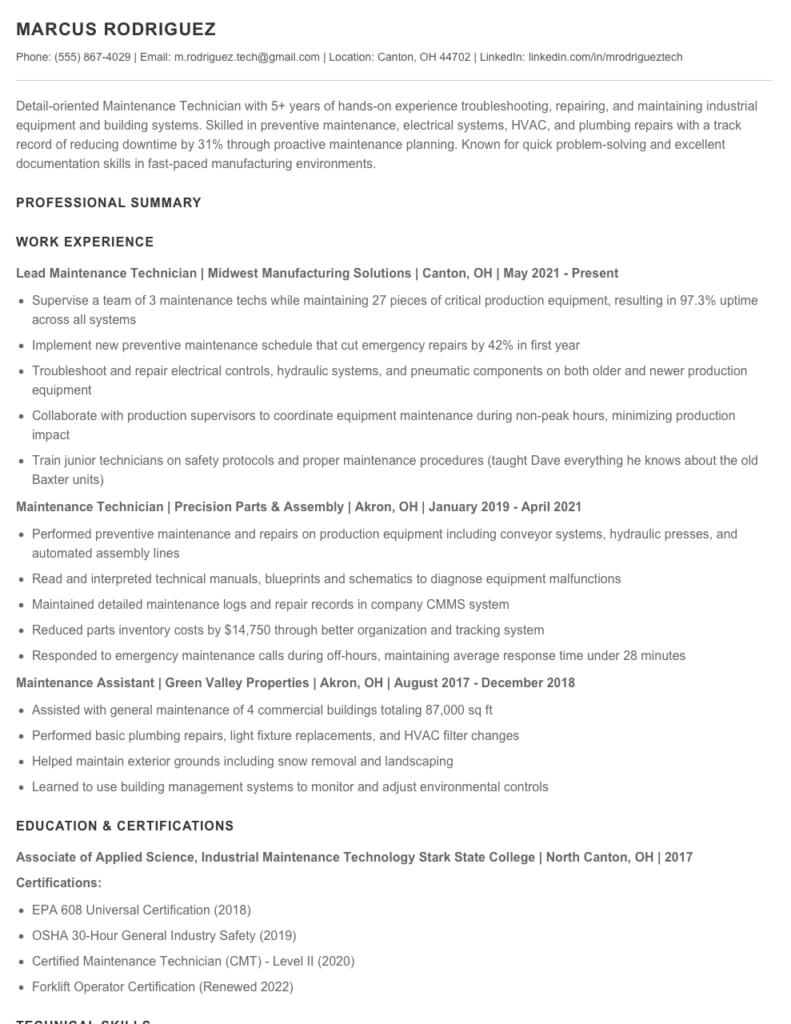

MARCUS RODRIGUEZ

(555) 867-4029 | ✉️ m.rodriguez.tech@gmail.com | Canton, OH 44702 | linkedin.com/in/mrodrigueztech

PROFESSIONAL SUMMARY

Detail-oriented Maintenance Technician with 5+ years of hands-on experience troubleshooting, repairing, and maintaining industrial equipment and building systems. Skilled in preventive maintenance, electrical systems, HVAC, and plumbing repairs with a track record of reducing downtime by 31% through proactive maintenance planning. Known for quick problem-solving and excellent documentation skills in fast-paced manufacturing environments.

WORK EXPERIENCE

Lead Maintenance Technician | Midwest Manufacturing Solutions | Canton, OH | May 2021 – Present

- Supervise a team of 3 maintenance techs while maintaining 27 pieces of critical production equipment, resulting in 97.3% uptime across all systems

- Implement new preventive maintenance schedule that cut emergency repairs by 42% in first year

- Troubleshoot and repair electrical controls, hydraulic systems, and pneumatic components on both older and newer production equipment

- Collaborate with production supervisors to coordinate equipment maintenance during non-peak hours, minimizing production impact

- Train junior technicians on safety protocols and proper maintenance procedures (taught Dave everything he knows about the old Baxter units)

Maintenance Technician | Precision Parts & Assembly | Akron, OH | January 2019 – April 2021

- Performed preventive maintenance and repairs on production equipment including conveyor systems, hydraulic presses, and automated assembly lines

- Read and interpreted technical manuals, blueprints and schematics to diagnose equipment malfunctions

- Maintained detailed maintenance logs and repair records in company CMMS system

- Reduced parts inventory costs by $14,750 through better organization and tracking system

- Responded to emergency maintenance calls during off-hours, maintaining average response time under 28 minutes

Maintenance Assistant | Green Valley Properties | Akron, OH | August 2017 – December 2018

- Assisted with general maintenance of 4 commercial buildings totaling 87,000 sq ft

- Performed basic plumbing repairs, light fixture replacements, and HVAC filter changes

- Helped maintain exterior grounds including snow removal and landscaping

- Learned to use building management systems to monitor and adjust environmental controls

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Industrial Maintenance Technology

Stark State College | North Canton, OH | 2017

Certifications:

- EPA 608 Universal Certification (2018)

- OSHA 30-Hour General Industry Safety (2019)

- Certified Maintenance Technician (CMT) – Level II (2020)

- Forklift Operator Certification (Renewed 2022)

TECHNICAL SKILLS

- Electrical Systems & Controls

- Hydraulic & Pneumatic Systems

- Welding (MIG, TIG)

- PLC Troubleshooting (Allen Bradley)

- Preventive Maintenance Planning

- HVAC Service & Repair

- Blueprint Reading

- Building Management Systems

- CMMS Software (eMaint, Maximo)

- Power Tools & Hand Tools

ADDITIONAL INFORMATION

Available for on-call emergency maintenance rotation. Clean driving record with valid CDL Class B license. Bilingual: English and Spanish (conversational).

Senior / Experienced Maintenance Technician Resume Example

MARCUS JENKINS

Cincinnati, OH 45202 • (513) 555-7612 • m.jenkins.tech@email.com

LinkedIn: linkedin.com/in/marcusjenkins-maintenance

Versatile Maintenance Technician with 10+ years of hands-on experience in manufacturing environments. Skilled troubleshooter with proven track record reducing downtime through preventive maintenance programs. Strong background in electrical systems, hydraulics, and pneumatics. Saved previous employer $87,000 annually by implementing equipment modification that extended machine life cycles.

PROFESSIONAL EXPERIENCE

SENIOR MAINTENANCE TECHNICIAN

Precision Manufacturing Solutions • Cincinnati, OH • March 2018 – Present

- Lead maintenance team of 5 technicians across 24/7 operations, supervising PM program for 32 CNC machines and auxiliary equipment

- Decreased production downtime by 31% through implementation of predictive maintenance schedule using vibration analysis

- Troubleshoot and repair complex electrical, mechanical, hydraulic and pneumatic systems in critical production equipment

- Developed and documented standard maintenance procedures, cutting training time for new techs from 6 weeks to 23 days

- Collaborated with engineering team to modify outdated equipment, extending useful life by 4-6 years and avoiding $175K in replacement costs

MAINTENANCE TECHNICIAN II

Cincinnati Metal Fabricators • Cincinnati, OH • June 2014 – March 2018

- Performed preventive and corrective maintenance on stamping presses, welding machines, and conveyor systems

- Rebuilt hydraulic cylinders and repaired pneumatic systems, reducing vendor repair costs by $42,000 annually

- Installed and maintained 480V 3-phase electrical systems according to NEC standards

- Created digital maintenance logs that improved tracking of recurring issues, helping identify root causes of equipment failures

- Trained and mentored 3 junior technicians on troubleshooting methodologies and safety procedures

MAINTENANCE ASSISTANT

Midwest Packaging Corp • Dayton, OH • August 2012 – June 2014

- Assisted senior technicians with daily maintenance tasks and emergency repairs

- Performed routine PMs on packaging equipment including conveyors, case packers, and palletizers

- Maintained parts inventory and organized tool crib, reducing parts retrieval time by 67%

- Helped implement 5S workplace organization standards in maintenance shop

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Industrial Maintenance Technology

Cincinnati State Technical & Community College, 2012

Certifications:

- CMRP (Certified Maintenance & Reliability Professional) – 2019

- NFPA 70E Electrical Safety Training – 2020, renewed 2023

- Hydraulic Systems Specialist – Eaton Corporation – 2017

- OSHA 30-Hour General Industry Safety – 2016

- Forklift Operator Certification – 2013, renewed 2022

TECHNICAL SKILLS

- Electrical Systems (AC/DC motors, VFDs, PLCs, controls)

- Mechanical Systems (bearings, gearboxes, chains, belts)

- Hydraulic & Pneumatic Systems

- Welding (MIG, TIG, Stick)

- Blueprint Reading & Schematic Interpretation

- Predictive/Preventive Maintenance Planning

- CMMS Software (eMaint, Maximo)

- Root Cause Analysis

- Allen Bradley PLC Programming (basic)

- Precision Measurement & Alignment

How to Write a Maintenance Technician Resume

Introduction

Landing a good maintenance technician job starts with a solid resume that showcases your technical skills, problem-solving abilities, and reliability. I've reviewed thousands of maintenance resumes over my career, and I'll tell you right now - most of them blend together in a sea of "fixed stuff, did PMs." The market's competitive, with facilities looking for techs who can minimize downtime and keep operations running smoothly. Your resume needs to stand out by highlighting specific systems you've worked with, measurable results, and your unique technical strengths.

Resume Structure and Format

Keep your resume clean and organized - just like your toolbox should be! Maintenance supervisors typically scan resumes for about 7 seconds before deciding whether to read further.

- Stick to 1-2 pages (1 page for junior techs, 2 pages max for veterans with 10+ years)

- Use a clean, readable font like Arial or Calibri in 11-12pt size

- Include clear section headers (Experience, Skills, Certifications)

- Format consistently - if one job title is bold, all should be

- Use reverse chronological order for work history

- Leave plenty of white space - cramped resumes get ignored

Profile/Summary Section

Your summary should be 3-4 lines that pack a punch. Don't waste space with vague statements like "Hardworking maintenance technician seeking new opportunities." Instead, highlight your specialties and years of experience.

Example: "HVAC-certified Maintenance Technician with 6+ years troubleshooting complex mechanical systems in manufacturing environments. Expertise in preventative maintenance programs that reduced emergency repairs by 37% at Johnson Manufacturing. Skilled in PLC troubleshooting, hydraulic systems, and equipment rebuilds."

Professional Experience

This is where most maintenance techs fall short. Don't just list responsibilities - show your impact! Each bullet should ideally follow this formula: Action + System/Equipment + Result.

- Start bullets with strong action verbs (Repaired, Implemented, Diagnosed, Fabricated)

- Specify equipment types and brands (Allen-Bradley PLCs, Trane HVAC units)

- Include numbers whenever possible (downtime reduction, PM completion rates)

- Highlight specialized skills (welding, electrical troubleshooting, blueprint reading)

- Mention CMMS systems you've used (SAP, Maximo, eMaint)

Pro Tip: Keep a "maintenance journal" at work. Jot down major repairs, projects, and wins as they happen. This makes resume updates way easier and gives you specific examples to share during interviews.

Education and Certifications

Maintenance is a field where certifications often matter more than degrees. List your most relevant and impressive credentials first.

- Technical diplomas or degrees (with completion years, not dates attended)

- Industry certifications (EPA, HVAC, electrical licenses)

- Safety training (OSHA, confined space, lock-out/tag-out)

- Equipment-specific training (manufacturer certifications)

- Relevant military training (for veterans)

Keywords and ATS Tips

Most maintenance job applications go through ATS (Applicant Tracking Systems) before human eyes see them. These systems scan for specific terms. Review each job posting carefully and include relevant keywords from it in your resume.

Common maintenance keywords to include:

- Preventative maintenance

- Troubleshooting

- Electrical/mechanical systems

- HVAC, plumbing, carpentry (specific to your skills)

- Work order management

- Equipment repair

- Facility maintenance

Industry-specific Terms

Demonstrate your knowledge by using industry terminology correctly. This signals to hiring managers that you know your stuff. Terms like PM schedules, predictive maintenance, CMMS, root cause analysis, and equipment-specific vocabulary show you speak the language of maintenance.

Common Mistakes to Avoid

- Being too vague ("responsible for maintenance") - get specific!

- Listing every single tool you've ever touched

- Focusing only on tasks rather than achievements

- Forgetting to proofread (nothing says "I don't pay attention to detail" like typos)

- Using the same resume for every application

Before/After Example

Before: "Responsible for fixing equipment and doing preventative maintenance."

After: "Diagnosed and repaired 14 production line motors, reducing unplanned downtime by 23% and saving approximately $87,000 in production losses. Implemented weekly PM schedule for hydraulic press systems using Maximo CMMS."

See the difference? The second example shows specific equipment, measurable results, and systems knowledge. That's what gets interviews!

Related Resume Examples

Soft skills for your Maintenance Technician resume

- Clear communication with non-technical staff when explaining maintenance issues (my supervisor once said I “translate technical jargon into English better than anyone”)

- Team coordination during emergency repairs – kept three separate departments informed during that major HVAC failure last winter

- Adaptability to shifting priorities when urgent issues arise mid-shift

- Patient mentoring of junior technicians – helped train 4 apprentices over the past 3 years

- Problem-solving under pressure, especially with limited parts availability

- Active listening during troubleshooting conversations with equipment operators

Hard skills for your Maintenance Technician resume

- HVAC Systems Troubleshooting & Repair (Type I & II EPA Certification)

- Electrical Wiring & Circuit Testing (up to 480V three-phase)

- Preventive Maintenance Program Implementation

- Plumbing & Pipefitting (copper, PVC, PEX)

- CMMS Software Proficiency (Maximo, eMaint)

- Welding (MIG, TIG) & Metal Fabrication

- Hydraulic & Pneumatic System Repair

- Forklift Operation & Certification (Class 3)

- Blueprint Reading & Technical Documentation