Machine Operator Resume examples & templates

Copyable Machine Operator Resume examples

What keeps our modern manufacturing world running 24/7, producing everything from the smartphone in your pocket to the car in your driveway? Behind every precision-engineered product stands a skilled Machine Operator—the unsung hero of production floors worldwide. These technical professionals don't just push buttons; they're the critical interface between sophisticated equipment and the products we rely on daily. With manufacturing automation increasing by nearly 37% since 2017, today's Machine Operators need a unique blend of mechanical aptitude and digital literacy that previous generations simply didn't require.

The field has transformed dramatically in recent years. Gone are the days of purely manual machine tending; today's operators often work with computer numerical control (CNC) systems, robotics, and integrated production networks. They troubleshoot complex issues, maintain quality standards, and keep production flowing—sometimes managing multiple stations simultaneously. As smart manufacturing continues to reshape factory floors, Machine Operators with both traditional skills and tech savvy will find themselves perfectly positioned for career advancement in an industry that's becoming more sophisticated by the day.

Junior Machine Operator Resume Example

MARCO RIVERA

Phone: (714) 555-9283 | Email: m.rivera@emailprovider.com

Location: Santa Ana, CA 92701 | LinkedIn: linkedin.com/in/marcor-machining

Detail-oriented Machine Operator with 1+ year of hands-on experience in CNC operation and manufacturing support. Quick learner who consistently maintains quality standards while meeting production targets. Experienced with routine maintenance procedures and quality inspection techniques in a fast-paced manufacturing environment.

EXPERIENCE

Machine Operator | Western Manufacturing Solutions | Santa Ana, CA | March 2023 – Present

- Operate 3 different CNC machines to produce metal components with tolerances of ±0.005″

- Perform daily equipment checks and basic maintenance, reducing unplanned downtime by 17%

- Inspect finished products using calipers, micrometers, and other precision measuring tools

- Document production outputs and quality metrics in company’s MRP system

- Trained 2 temp workers on proper machine operation and safety protocols

Production Assistant | Western Manufacturing Solutions | Santa Ana, CA | August 2022 – March 2023

- Assisted machine operators by preparing materials and removing finished parts

- Performed basic quality checks on manufactured components

- Maintained clean work areas according to 5S standards

- Packaged finished products for shipping according to customer specifications

Warehouse Associate (Part-time) | QuickShip Logistics | Anaheim, CA | May 2021 – July 2022

- Loaded and unloaded delivery trucks while maintaining accurate inventory counts

- Used handheld scanners to track package movement through warehouse

- Helped reorganize storage area, improving space utilization by 23%

EDUCATION

Certificate in Manufacturing Technology | Orange County Technical College | 2022

High School Diploma | Santa Ana High School | 2021

CERTIFICATIONS

OSHA 10-Hour General Industry Safety (2022)

Forklift Operator Certification (2022)

SKILLS

- CNC Machine Operation

- Blueprint Reading (basic)

- Quality Inspection

- Preventive Maintenance

- Measuring Instruments

- MRP Systems

- Equipment Troubleshooting

- Safety Compliance

- 5S Methodology

- Microsoft Excel (basic)

ADDITIONAL INFORMATION

Available for all shifts | Bilingual: English and Spanish | Clean driving record

Mid-level Machine Operator Resume Example

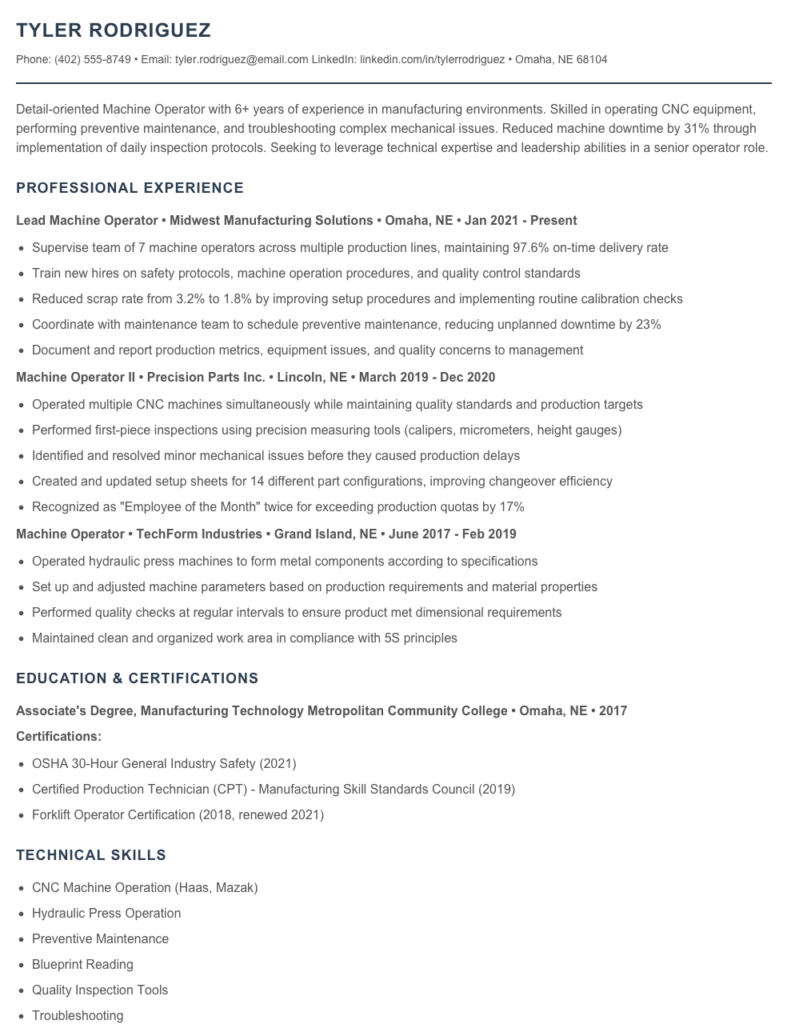

Tyler Rodriguez

Phone: (402) 555-8749 • Email: tyler.rodriguez@email.com

LinkedIn: linkedin.com/in/tylerrodriguez • Omaha, NE 68104

Detail-oriented Machine Operator with 6+ years of experience in manufacturing environments. Skilled in operating CNC equipment, performing preventive maintenance, and troubleshooting complex mechanical issues. Reduced machine downtime by 31% through implementation of daily inspection protocols. Seeking to leverage technical expertise and leadership abilities in a senior operator role.

PROFESSIONAL EXPERIENCE

Lead Machine Operator • Midwest Manufacturing Solutions • Omaha, NE • Jan 2021 – Present

- Supervise team of 7 machine operators across multiple production lines, maintaining 97.6% on-time delivery rate

- Train new hires on safety protocols, machine operation procedures, and quality control standards

- Reduced scrap rate from 3.2% to 1.8% by improving setup procedures and implementing routine calibration checks

- Coordinate with maintenance team to schedule preventive maintenance, reducing unplanned downtime by 23%

- Document and report production metrics, equipment issues, and quality concerns to management

Machine Operator II • Precision Parts Inc. • Lincoln, NE • March 2019 – Dec 2020

- Operated multiple CNC machines simultaneously while maintaining quality standards and production targets

- Performed first-piece inspections using precision measuring tools (calipers, micrometers, height gauges)

- Identified and resolved minor mechanical issues before they caused production delays

- Created and updated setup sheets for 14 different part configurations, improving changeover efficiency

- Recognized as “Employee of the Month” twice for exceeding production quotas by 17%

Machine Operator • TechForm Industries • Grand Island, NE • June 2017 – Feb 2019

- Operated hydraulic press machines to form metal components according to specifications

- Set up and adjusted machine parameters based on production requirements and material properties

- Performed quality checks at regular intervals to ensure product met dimensional requirements

- Maintained clean and organized work area in compliance with 5S principles

EDUCATION & CERTIFICATIONS

Associate’s Degree, Manufacturing Technology

Metropolitan Community College • Omaha, NE • 2017

Certifications:

- OSHA 30-Hour General Industry Safety (2021)

- Certified Production Technician (CPT) – Manufacturing Skill Standards Council (2019)

- Forklift Operator Certification (2018, renewed 2021)

TECHNICAL SKILLS

- CNC Machine Operation (Haas, Mazak)

- Hydraulic Press Operation

- Preventive Maintenance

- Blueprint Reading

- Quality Inspection Tools

- Troubleshooting

- SAP Manufacturing Module

- GD&T (Geometric Dimensioning & Tolerancing)

- Machine Setup & Changeover

- Basic Welding (MIG)

ADDITIONAL INFORMATION

Available for all shifts • Willing to work overtime as needed • Clean driving record

Senior / Experienced Machine Operator Resume Example

Derek R. Townsend

Charlotte, NC 28202 • (704) 555-8176 • dtownsend83@gmail.com • linkedin.com/in/derektownsend

PROFESSIONAL SUMMARY

Seasoned Machine Operator with 9+ years of experience in high-volume manufacturing environments. Skilled in operating CNC machines, injection molding equipment, and automated assembly systems with a track record of reducing downtime by 17%. Known for troubleshooting complex mechanical issues and implementing preventive maintenance procedures that extended machine life spans by 2-3 years.

PROFESSIONAL EXPERIENCE

Senior Machine Operator | Carolina Manufacturing Solutions | Charlotte, NC | June 2019 – Present

- Lead a team of 6 machine operators across 3 shifts, providing technical guidance and training on complex equipment operations

- Operate 5 different CNC machines simultaneously, maintaining 97.3% uptime while ensuring quality standards are met

- Implemented a new preventive maintenance schedule that reduced unexpected breakdowns by 28% and saved approximately $43,500 in repair costs annually

- Collaborate with engineering team to optimize production processes, resulting in 16% increased throughput on the main assembly line

- Recognized as “Employee of the Quarter” twice for suggesting process improvements that reduced material waste by 9%

Machine Operator II | Precision Parts, Inc. | Gastonia, NC | March 2016 – May 2019

- Operated and monitored 3 injection molding machines producing automotive components with tolerances of ±0.002 inches

- Performed quality checks on finished products using calipers, micrometers, and other precision measuring tools

- Maintained detailed production logs and identified recurring issues that led to a 12% improvement in first-pass yield

- Trained 4 entry-level operators on safety protocols and basic machine operation procedures

Machine Operator | GreenTech Manufacturing | Rock Hill, SC | August 2014 – February 2016

- Operated stamping and forming equipment to produce sheet metal components for commercial HVAC systems

- Conducted routine maintenance including lubricating moving parts and replacing worn components

- Caught a critical flaw in die setup that would have resulted in an entire batch rejection (est. value $27,000)

- Assisted with inventory management of raw materials and finished goods

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Manufacturing Technology

Central Piedmont Community College, Charlotte, NC | 2014

Certifications:

- OSHA 30-Hour General Industry Safety Certification (2022)

- Certified Production Technician (CPT) – Manufacturing Skill Standards Council (2019)

- CNC Machine Operation Level II – National Institute for Metalworking Skills (2018)

- Forklift Operator Certification (renewed 2023)

TECHNICAL SKILLS

- CNC Machine Operation (Haas, Mazak, Okuma)

- Injection Molding Processes

- Preventive Maintenance

- Quality Control & Inspection

- Blueprint Reading

- Precision Measurement Tools

- Mechanical Troubleshooting

- PLC Basics & HMI Operation

- Basic CAD/CAM Software

- 5S and Lean Manufacturing Principles

ADDITIONAL INFORMATION

Available for all shifts • Bilingual (English/Spanish) • Clean safety record (zero incidents in 9 years)

How to Write a Machine Operator Resume

Introduction

Landing that machine operator job means showcasing both your technical skills and reliability on one or two pages of paper. Your resume isn't just a list of past jobs—it's a marketing tool that tells employers "I can run your equipment safely, efficiently, and with minimal downtime." I've helped hundreds of manufacturing professionals land interviews, and I've noticed hiring managers typically spend just 7-12 seconds on initial resume scans. Let's make those seconds count!

Put yourself in the maintenance supervisor's shoes: they need someone who won't just show up, but who'll keep production flowing smoothly. Your resume should scream "dependable" and "skilled" without actually using those exact words.

Resume Structure and Format

Keep your resume clean and readable—just like you'd keep your workstation. For machine operators, function beats flash every time.

- Stick to 1-2 pages (1 page for those with under 5 years experience)

- Use a simple, readable font like Arial or Calibri in 11-12pt size

- Include clear section headings with slight visual separation

- Maintain consistent formatting throughout (dates, bullet points, etc.)

- Save as PDF to preserve formatting across devices

Profile/Summary Section

Your professional summary should be 3-4 lines that pack a punch. Think of it as your "elevator pitch" to the hiring manager. For a machine operator role, focus on your years of experience, equipment proficiency, and standout achievements.

Example: "CNC machine operator with 6+ years running Haas vertical mills and lathes. Maintained 97.3% uptime while reducing material waste by 14% at Thompson Manufacturing. Skilled in troubleshooting, quality inspection, and reading GD&T blueprints."

Professional Experience

This is where you prove you're worth interviewing. Don't just list duties—show impact!

- Start bullets with strong action verbs (Operated, Maintained, Calibrated)

- Include specific machines you've operated (brand names matter!)

- Mention production rates, accuracy percentages, or safety records

- Highlight preventative maintenance skills and problem-solving examples

- Note any cross-training or leadership responsibilities

Weak: "Responsible for operating machinery"

Strong: "Operated 5 Allen Bradley injection molding machines, consistently exceeding daily production targets by 8-12% while maintaining quality rejection rates below 0.5%"

Education and Certifications

Many machine operator positions don't require advanced degrees, but any relevant education or training strengthens your case. List these in reverse chronological order:

- High school diploma or GED

- Technical/vocational training

- Certifications (OSHA, Forklift, Six Sigma, etc.)

- On-the-job training programs

- Continuing education courses

Keywords and ATS Tips

Most companies use Applicant Tracking Systems to filter resumes before human eyes ever see them. To get past these digital gatekeepers:

- Match keywords from the job posting (equipment types, skills)

- Use standard section headings (Experience, Skills, Education)

- Avoid tables, headers/footers, and fancy formatting

- Skip the objective statement (outdated and wastes space)

- Include your phone, email, and city/state (full address not needed)

Industry-specific Terms

Pepper these throughout your resume to signal that you speak the language:

- Preventative maintenance

- Quality control/assurance

- Setup and changeover

- Lean manufacturing/5S

- SOP (Standard Operating Procedures)

- Troubleshooting

- Cycle time

- Tolerance specifications

Common Mistakes to Avoid

- Being vague about equipment experience (list specific machines)

- Forgetting to mention safety record or training

- Using technical jargon without explaining productivity impact

- Including irrelevant personal information

- Typos! (Nothing says "I don't pay attention to detail" like misspellings)

Before/After Example

Before: "Worked on different machines and made parts according to specs."

After: "Operated Mazak CNC turning centers to produce aerospace components with tolerances to ±0.0005". Reduced setup time from 42 to 29 minutes through process improvements, contributing to 16% increase in daily output."

Your resume is your ticket to the interview—make it count! Tailor it for each job application, focusing on the skills and experiences most relevant to that specific position. And remember, in manufacturing, measurable results speak volumes.

Related Resume Examples

Soft skills for your Machine Operator resume

- Troubleshooting under pressure — able to quickly diagnose mechanical issues while maintaining production targets (saved 12 hours of downtime last quarter)

- Team coordination across shifts — smooth handoffs with clear documentation to prevent costly mistakes

- Safety advocacy — spot potential hazards before they cause problems; trained 4 new hires on proper protocol

- Maintenance communication — explain technical issues clearly to repair teams without manufacturing jargon

- Adaptability to changing production needs — quick setup changes when priorities shift (typically under 35 minutes)

- Process improvement mindset — suggested material handling modification that reduced scrap by 7%

Hard skills for your Machine Operator resume

- CNC Machine Programming (Fanuc, Siemens)

- Preventative Maintenance Techniques

- Blueprint & Technical Drawing Interpretation

- Quality Control & Statistical Process Control (SPC)

- Hydraulic & Pneumatic Systems Troubleshooting

- OSHA Safety Standards & Lockout/Tagout Procedures

- Injection Molding Process Optimization

- Manufacturing Execution Systems (MES) Operation

- Precision Measurement Tools (Micrometers, Calipers, CMM)