Heavy Equipment Operator Resume examples & templates

Copyable Heavy Equipment Operator Resume examples

What if the office with the best view in the world isn't an office at all, but the cab of a 30-ton excavator? For thousands of heavy equipment operators across the country, that's exactly the case. These skilled professionals—the ones who transform blueprints into highways, shape raw earth into foundations, and make the impossible possible—are the backbone of America's construction industry. And right now, they're in serious demand. With infrastructure spending hitting $1.2 trillion through recent federal initiatives, heavy equipment operators are looking at job growth that's outpacing the national average by nearly 5%.

The field has changed dramatically in the last decade. GPS-guided grading systems, semi-autonomous equipment, and advanced simulation training have revolutionized how operators work. Gone are the days when brute strength was enough; today's equipment operator needs a blend of technical know-how, spatial awareness, and precision that rivals surgeons (just with bigger tools and better pay). As construction methods continue evolving toward greater efficiency and sustainability, skilled operators who can adapt to these technologies will find themselves not just building America's infrastructure, but building impressive careers along the way.

Junior Heavy Equipment Operator Resume Example

MARCUS RIVERA

Phone: (509) 721-4388 | Email: m.rivera92@gmail.com | Yakima, WA 98901

LinkedIn: linkedin.com/in/marcusrivera92

Dependable Heavy Equipment Operator with 1+ year of hands-on experience operating bulldozers, excavators, and loaders. Completed 800+ hours of equipment operation with zero safety incidents. Looking to leverage my mechanical aptitude and NCCCO certification to contribute to a growing construction team. Physically fit with ability to work in various weather conditions and follow precise instructions.

EXPERIENCE

Junior Heavy Equipment Operator

Pacific Northwest Construction – Yakima, WA

March 2023 – Present

- Operate Cat D6 dozers, 336 excavators, and 966 wheel loaders for site preparation and excavation projects

- Perform daily equipment inspections catching 3 potential hydraulic failures before they caused downtime

- Excavate trenches and foundations with accuracy within 0.5 inch of specifications

- Maintain communication with ground crew using hand signals and radio to ensure site safety

- Complete daily equipment logs and maintenance records for fleet of 8 machines

Equipment Operator Apprentice

Cascade Earthworks – Ellensburg, WA

August 2022 – February 2023

- Trained under supervision of senior operators on proper operation of backhoes and skid steers

- Assisted with grading operations and material placement on 4 residential development sites

- Helped maintain equipment by performing basic service tasks (greasing, fluid checks, filter changes)

- Learned to read grade stakes and construction plans to understand job requirements

General Laborer

Wilson Construction – Yakima, WA

May 2022 – July 2022

- Supported construction operations by directing truck traffic and setting up safety barriers

- Performed manual excavation work in areas inaccessible to heavy machinery

- Gained firsthand exposure to construction workflows and equipment operations

EDUCATION & CERTIFICATIONS

Heavy Equipment Operator Training Program

West Coast Training – Woodland, WA

Certificate of Completion – April 2022

Certifications:

- NCCCO (National Commission for the Certification of Crane Operators) – Mobile Crane Operator

- OSHA 10-Hour Construction Safety

- First Aid/CPR Certified

- WA Class A CDL with Tanker & Hazmat Endorsements

SKILLS

- Equipment Operation: Bulldozers, Excavators, Backhoes, Loaders, Skid Steers

- Preventative Maintenance

- Grade Reading & Site Plans

- Trench Safety Procedures

- GPS Machine Control Systems (basic)

- Radio Communications

- Load Calculation

- Basic Mechanical Repairs

- Material Handling & Stockpiling

- Microsoft Office (basic)

ADDITIONAL INFORMATION

Available for overnight travel and emergency call-outs. Willing to work weekends and extended hours during peak construction season.

Mid-level Heavy Equipment Operator Resume Example

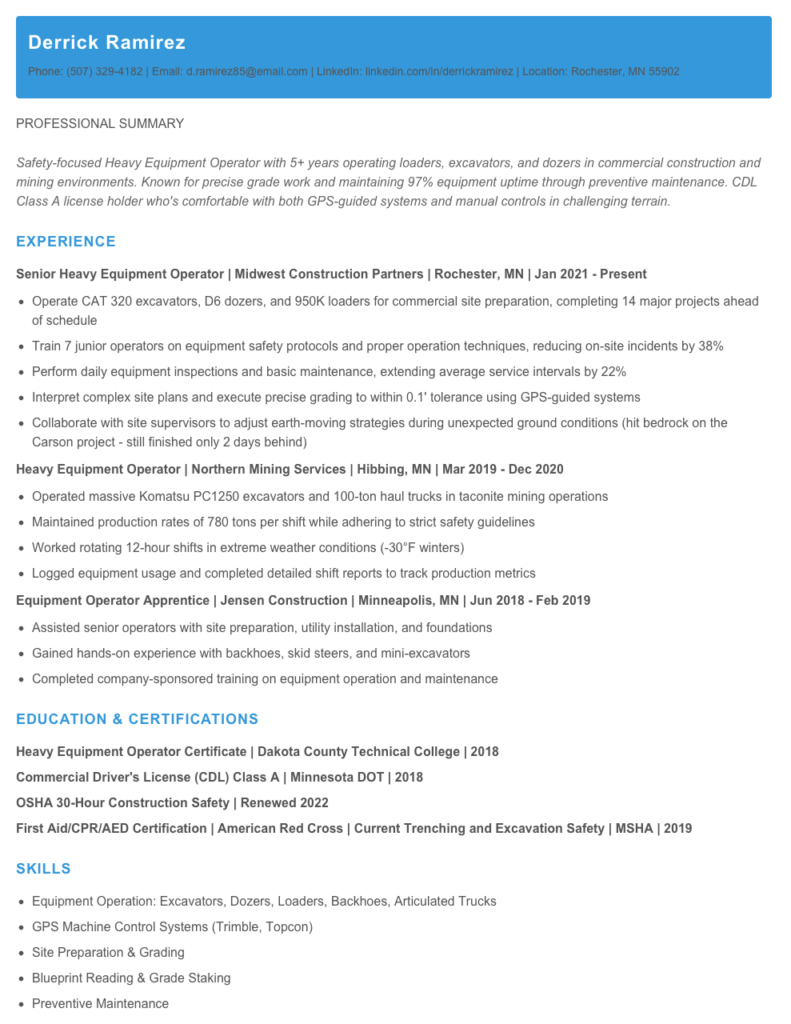

Derrick Ramirez

(507) 329-4182 | d.ramirez85@email.com | linkedin.com/in/derrickramirez | Rochester, MN 55902

PROFESSIONAL SUMMARY

Safety-focused Heavy Equipment Operator with 5+ years operating loaders, excavators, and dozers in commercial construction and mining environments. Known for precise grade work and maintaining 97% equipment uptime through preventive maintenance. CDL Class A license holder who’s comfortable with both GPS-guided systems and manual controls in challenging terrain.

EXPERIENCE

Senior Heavy Equipment Operator | Midwest Construction Partners | Rochester, MN | Jan 2021 – Present

- Operate CAT 320 excavators, D6 dozers, and 950K loaders for commercial site preparation, completing 14 major projects ahead of schedule

- Train 7 junior operators on equipment safety protocols and proper operation techniques, reducing on-site incidents by 38%

- Perform daily equipment inspections and basic maintenance, extending average service intervals by 22%

- Interpret complex site plans and execute precise grading to within 0.1′ tolerance using GPS-guided systems

- Collaborate with site supervisors to adjust earth-moving strategies during unexpected ground conditions (hit bedrock on the Carson project – still finished only 2 days behind)

Heavy Equipment Operator | Northern Mining Services | Hibbing, MN | Mar 2019 – Dec 2020

- Operated massive Komatsu PC1250 excavators and 100-ton haul trucks in taconite mining operations

- Maintained production rates of 780 tons per shift while adhering to strict safety guidelines

- Worked rotating 12-hour shifts in extreme weather conditions (-30°F winters)

- Logged equipment usage and completed detailed shift reports to track production metrics

Equipment Operator Apprentice | Jensen Construction | Minneapolis, MN | Jun 2018 – Feb 2019

- Assisted senior operators with site preparation, utility installation, and foundations

- Gained hands-on experience with backhoes, skid steers, and mini-excavators

- Completed company-sponsored training on equipment operation and maintenance

EDUCATION & CERTIFICATIONS

Heavy Equipment Operator Certificate | Dakota County Technical College | 2018

Commercial Driver’s License (CDL) Class A | Minnesota DOT | 2018

OSHA 30-Hour Construction Safety | Renewed 2022

First Aid/CPR/AED Certification | American Red Cross | Current Trenching and Excavation Safety | MSHA | 2019

SKILLS

- Equipment Operation: Excavators, Dozers, Loaders, Backhoes, Articulated Trucks

- GPS Machine Control Systems (Trimble, Topcon)

- Site Preparation & Grading

- Blueprint Reading & Grade Staking

- Preventive Maintenance

- Load Calculation & Material Estimation

- Confined Space Operations

- Heavy Rigging & Signaling

- Winter Operations & Snow Removal

- Radio Communications

ADDITIONAL INFORMATION

Available for emergency call-outs and weekend work when needed. Clean driving record with no moving violations in past 7 years. Familiar with both union and non-union job sites.

Senior / Experienced Heavy Equipment Operator Resume Example

MICHAEL J. HARRINGTON

Raleigh, NC | (919) 555-8124 | mjharrington@email.com | linkedin.com/in/michaelharrington

PROFESSIONAL SUMMARY

Safety-focused Heavy Equipment Operator with 12+ years handling complex machinery in challenging construction environments. Known for precision excavation work and ability to read site plans accurately while maintaining production schedules. Experienced mentor who’s trained 14 junior operators and maintained a perfect safety record for the past 7 years despite working in high-risk environments.

EXPERIENCE

SENIOR HEAVY EQUIPMENT OPERATOR | Davidson Construction Group | April 2018 – Present

- Operate multiple heavy machinery types including excavators, bulldozers, front-end loaders, and backhoes on commercial construction projects valued at $5-22M

- Lead a team of 6 equipment operators, providing daily direction and safety briefings that reduced reportable incidents by 37% in first year

- Developed and implemented new preventative maintenance schedule that extended equipment life by an estimated 14% and reduced downtime by 23%

- Completed precision excavation for hospital expansion project with zero utility strikes despite working within 8 inches of critical infrastructure

- Train new operators on company equipment protocols and safety regulations (certified 9 operators since 2019)

HEAVY EQUIPMENT OPERATOR | Piedmont Excavation Services | June 2014 – March 2018

- Operated Cat 320 excavators, D6 dozers, and Komatsu PC200 excavators for residential and light commercial projects

- Performed mass excavation, trenching, and fine grading work meeting grade tolerances within 0.1 foot

- Implemented GPS machine control system on dozers that improved productivity by 31% and reduced material waste

- Maintained daily logs of machine hours, fuel consumption, and maintenance needs that helped identify $27,400 in annual cost savings

EQUIPMENT OPERATOR | Taylor Brothers Construction | August 2011 – May 2014

- Operated skid steers, backhoes, and mini-excavators for residential foundation work and utility installation

- Performed routine maintenance on equipment including fluid checks, filter changes, and track tension adjustments

- Helped implement new safety protocols that led to 632 consecutive days without a lost-time accident

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Construction Equipment Operation

Wake Technical Community College | Raleigh, NC | 2011

Certifications:

- OSHA 30-Hour Construction Safety (renewed 2022)

- First Aid/CPR/AED Certification (current)

- NCCCO Certified Crane Operator (since 2016)

- Excavation Safety Competent Person Certification

- Trench Safety Certification

SKILLS

- Equipment: Excavators, Bulldozers, Front-end Loaders, Backhoes, Skid Steers, Rollers, Graders

- Technical: Laser Levels, Grade Setting, GPS Machine Control, Blueprint Reading

- Maintenance: Preventative Maintenance, Basic Repairs, Troubleshooting

- Computer: Equipment Management Software, Daily Reporting Apps, Basic MS Office

- Safety: Confined Space Entry, Trenching/Excavation Safety, LOTO Procedures

- Soft Skills: Team Leadership, Mentoring, Problem-Solving, Communication

ADDITIONAL INFORMATION

Valid Commercial Driver’s License (CDL) Class A with Tanker Endorsement

Willing to travel up to 75 miles for project work

Availability for emergency response work during natural disasters

How to Write a Heavy Equipment Operator Resume

Introduction

Let's be straight about something — a solid resume can make or break your chances in the competitive heavy equipment operator field. I've spent the last 15+ years reviewing thousands of resumes, and the difference between getting an interview and getting ignored often comes down to how well you showcase your skills on paper. Heavy equipment jobs pay well (median salary of $48,290 according to BLS data), but they also attract plenty of qualified applicants. Your resume needs to stand out while hitting all the right technical marks.

Resume Structure and Format

Keep your resume clean and readable — just like you keep your equipment. Aim for 1-2 pages max, with clear section headings and consistent formatting. Construction and equipment operation are precision industries, so your resume should reflect that attention to detail.

- Stick with standard fonts (Arial, Calibri, Times New Roman) at 10-12pt size

- Use bold for section headings and job titles

- Include plenty of white space — cramped resumes get skimmed or skipped

- Save as PDF to preserve formatting (unless specifically asked for Word format)

- Name your file professionally: "JohnSmith_HeavyEquipmentOperator.pdf"

Profile/Summary Section

Your profile should be short (3-5 lines) but powerful. This isn't where you tell your life story! Focus on years of experience, types of equipment you've mastered, safety record, and any standout credentials. Think of it as your "elevator pitch" to a busy superintendent who's reviewing 50+ resumes.

Don't just say you're "experienced" or "skilled" — specify exactly what machines you can operate and in what contexts. "Skilled excavator operator" becomes "8 years operating CAT 320 excavators in pipeline and commercial excavation projects with zero recordable incidents."

Professional Experience

This is the meat of your resume. For each position, include:

- Company name and location

- Your exact title (don't embellish)

- Dates employed (month/year format)

- 4-6 bullet points highlighting responsibilities and achievements

When writing bullet points, start with strong action verbs (Operated, Maintained, Excavated) and include specific equipment models, project types, and measurable results. For example:

- Operated D6 dozers and 14M motor graders on highway expansion project, consistently meeting 117% of daily production targets

- Maintained zero safety incidents over 2,400 equipment hours while working in high-traffic zones

- Reduced fuel consumption by 14% through proper machine operation techniques

Education and Certifications

In this field, certifications often matter more than formal education. List relevant certifications first, followed by any education. Include:

- Equipment-specific certifications (include cert numbers if applicable)

- OSHA training (10-hour, 30-hour)

- CDL license and class

- High school diploma or GED

- Any relevant vocational training or apprenticeships

Keywords and ATS Tips

Most companies now use Applicant Tracking Systems to filter resumes before a human ever sees them. These systems scan for specific keywords, so you need to incorporate terms from the job posting. Common keywords for heavy equipment operators include:

- Equipment types (backhoe, excavator, bulldozer, grader, loader)

- Brand names (Caterpillar, John Deere, Komatsu, Volvo)

- Skills (grading, excavation, demolition, site preparation)

- Certifications (NCCCO, OSHA, CDL)

- Software (if relevant - some modern equipment uses computerized systems)

Industry-specific Terms

Use terminology that shows you know the industry. Terms like compaction, grade checking, sloping, trenching, and backfilling demonstrate familiarity with the work. If you've worked with GPS/laser guided equipment, definitely mention it — this technology is increasingly important and shows you're up-to-date with industry advancements.

Common Mistakes to Avoid

- Listing equipment without specifying models or experience level

- Focusing only on responsibilities rather than achievements

- Omitting safety record or training

- Using general terms instead of specific project types

- Forgetting to update contact info (I've seen this more than you'd think!)

Before/After Example

Before: "Operated heavy equipment at construction sites."

After: "Operated CAT 336 excavators and D6 dozers across 7 commercial construction sites, completing foundation excavations 2 days ahead of schedule on 4 consecutive projects while maintaining Grade A safety rating."

See the difference? The second version gives specifics that prove your abilities rather than just claiming them. Remember — your resume isn't just a history of where you've worked, it's evidence of what you can do for your next employer.

Related Resume Examples

Soft skills for your Heavy Equipment Operator resume

- Team coordination in high-pressure environments (worked with 6-person crews on time-sensitive excavation projects)

- Equipment troubleshooting – quick diagnosis of mechanical issues before they become costly repairs

- Safety-focused communication that balances efficiency with accident prevention

- Mentoring junior operators on equipment care and proper technique

- Adaptability to changing weather conditions and site requirements without compromising quality

- Spatial awareness and precision control (can operate in tight spaces with minimal clearance)

Hard skills for your Heavy Equipment Operator resume

- CDL Class A with Hazmat and Tanker endorsements

- Hydraulic excavator operation (tracked and wheeled up to 50-ton)

- Trimble GPS machine control systems

- Caterpillar D6 dozer with 6-way blade proficiency

- OSHA 30-Hour Construction certification

- Preventive maintenance and field repairs

- Load calculation and rigging techniques

- Blueprint and grade stake reading

- JD Edwards maintenance tracking software