Diesel Mechanic Resume examples & templates

Copyable Diesel Mechanic Resume examples

That massive 15-liter diesel engine staring back at you with its complex electronic control modules and emission systems bears little resemblance to the straightforward mechanical beasts of 20 years ago. For today's diesel mechanics, keeping up with rapidly evolving technology while still maintaining the core hands-on skills of the trade can feel like working two jobs simultaneously. The diagnostic computer might tell you there's a problem with the EGR system, but it won't show you how to access that impossibly positioned sensor behind the turbocharger.

Despite these challenges, diesel mechanics remain in high demand—with the Bureau of Labor Statistics projecting a 7.4% growth rate through 2030, translating to about 28,100 new positions annually. Much of this demand stems from the growing sophistication of diesel systems and the integration of alternative fuel technologies. Fleet operators can't afford downtime; a single truck out of commission can cost upwards of $1,000 per day in lost revenue. As the transportation industry continues its gradual shift toward cleaner diesel technologies and eventually hybrid systems, mechanics with both traditional mechanical expertise and advanced diagnostic skills will find themselves increasingly valuable. The grease under your fingernails might be the same, but the skills in your head will need to keep evolving.

Junior Diesel Mechanic Resume Example

MARCUS REYNOLDS

Phone: (412) 555-7891 | Email: m.reynolds@email.com

Pittsburgh, PA 15203 | LinkedIn: linkedin.com/in/marcusreynolds

PROFESSIONAL SUMMARY

Recent Diesel Technology graduate with hands-on experience diagnosing and repairing diesel engines, transmissions, and electrical systems. Completed 450+ hours of practical training and 6-month apprenticeship at Patterson Truck Repair. Currently ASE Entry-Level certified with strong mechanical aptitude and commitment to safety protocols. Seeking to grow my career with a company that values reliability and technical skill development.

EXPERIENCE

Diesel Mechanic Assistant | Keystone Fleet Services | Pittsburgh, PA | January 2023 – Present

- Perform preventative maintenance on fleet of 37 Class 8 trucks including oil changes, brake inspections, and fluid checks

- Assist senior mechanics with diagnostics and repairs of Detroit Diesel and Cummins engines

- Document all service work in company tracking system, maintaining 98% accuracy rate

- Organize parts inventory and maintain clean, safe work environment

- Recently began handling basic repairs independently after demonstrating consistent competence

Diesel Mechanic Apprentice | Patterson Truck Repair | Pittsburgh, PA | July 2022 – December 2022

- Completed 6-month intensive apprenticeship program working alongside 2 master mechanics

- Gained experience with electrical diagnostics using multimeters and diagnostic software

- Performed basic repairs on braking systems, exhaust systems, and cooling systems

- Assisted with complete engine overhaul on Peterbilt 579 with Paccar MX-13 engine

Maintenance Helper (Part-time) | Miller Construction Equipment | Pittsburgh, PA | May 2021 – May 2022

- Performed basic maintenance on construction equipment while completing diesel technology program

- Changed oil, filters, and fluids on bulldozers, excavators, and loaders

- Cleaned and organized shop tools and equipment

- Shadowed mechanics during complex repairs to gain practical knowledge

EDUCATION & CERTIFICATIONS

Associate of Applied Science in Diesel Technology

Pittsburgh Technical College | Pittsburgh, PA | Graduated May 2022

Certifications:

- ASE Entry-Level Certification – Diesel Engines (2022)

- ASE Entry-Level Certification – Electrical/Electronic Systems (2022)

- OSHA 10-Hour Safety Certification (2021)

- EPA 609 Certification for Refrigerant Recovery (2022)

TECHNICAL SKILLS

- Preventative maintenance (PM) services

- Basic engine diagnostics & repair

- Brake system service & adjustment

- Electrical system troubleshooting

- Digital diagnostic tools (JPRO, Nexiq)

- Hydraulic system maintenance

- Welding fundamentals (MIG)

- Parts inventory management

- Service documentation & record keeping

- Forklift operation

ADDITIONAL INFORMATION

Willing to work flexible shifts including weekends and evenings. Clean driving record with Class B CDL permit. Own complete set of hand tools.

Mid-level Diesel Mechanic Resume Example

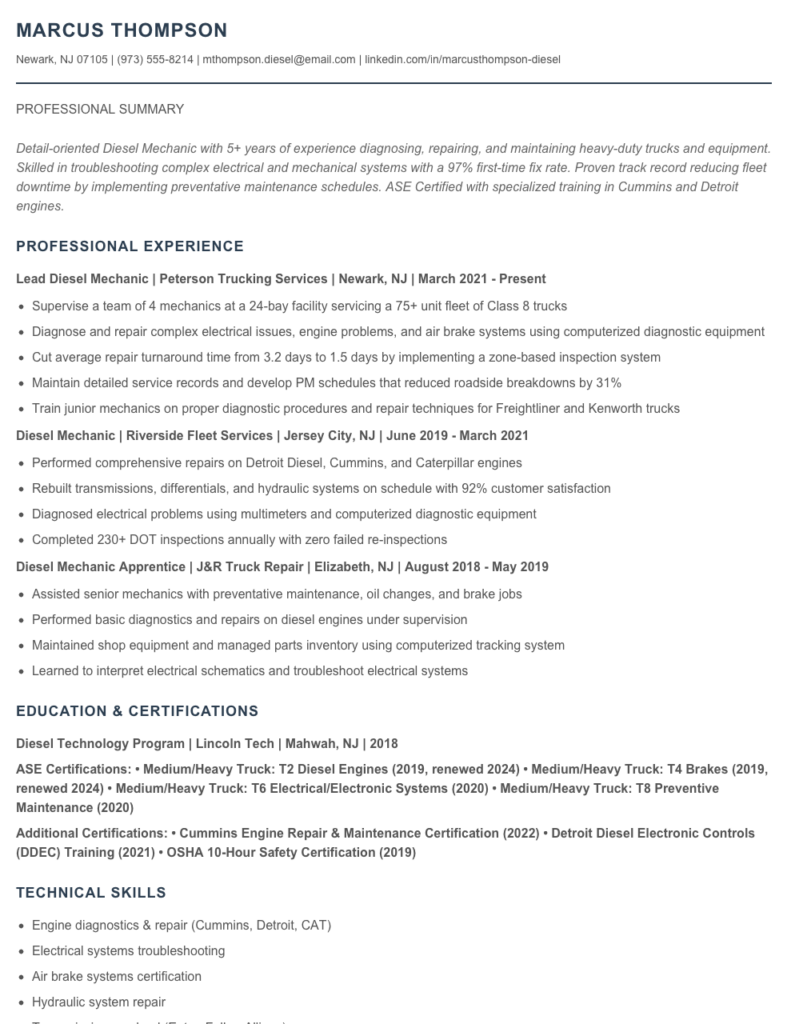

MARCUS THOMPSON

Newark, NJ 07105 | (973) 555-8214 | mthompson.diesel@email.com | linkedin.com/in/marcusthompson-diesel

PROFESSIONAL SUMMARY

Detail-oriented Diesel Mechanic with 5+ years of experience diagnosing, repairing, and maintaining heavy-duty trucks and equipment. Skilled in troubleshooting complex electrical and mechanical systems with a 97% first-time fix rate. Proven track record reducing fleet downtime by implementing preventative maintenance schedules. ASE Certified with specialized training in Cummins and Detroit engines.

PROFESSIONAL EXPERIENCE

Lead Diesel Mechanic | Peterson Trucking Services | Newark, NJ | March 2021 – Present

- Supervise a team of 4 mechanics at a 24-bay facility servicing a 75+ unit fleet of Class 8 trucks

- Diagnose and repair complex electrical issues, engine problems, and air brake systems using computerized diagnostic equipment

- Cut average repair turnaround time from 3.2 days to 1.5 days by implementing a zone-based inspection system

- Maintain detailed service records and develop PM schedules that reduced roadside breakdowns by 31%

- Train junior mechanics on proper diagnostic procedures and repair techniques for Freightliner and Kenworth trucks

Diesel Mechanic | Riverside Fleet Services | Jersey City, NJ | June 2019 – March 2021

- Performed comprehensive repairs on Detroit Diesel, Cummins, and Caterpillar engines

- Rebuilt transmissions, differentials, and hydraulic systems on schedule with 92% customer satisfaction

- Diagnosed electrical problems using multimeters and computerized diagnostic equipment

- Completed 230+ DOT inspections annually with zero failed re-inspections

Diesel Mechanic Apprentice | J&R Truck Repair | Elizabeth, NJ | August 2018 – May 2019

- Assisted senior mechanics with preventative maintenance, oil changes, and brake jobs

- Performed basic diagnostics and repairs on diesel engines under supervision

- Maintained shop equipment and managed parts inventory using computerized tracking system

- Learned to interpret electrical schematics and troubleshoot electrical systems

EDUCATION & CERTIFICATIONS

Diesel Technology Program | Lincoln Tech | Mahwah, NJ | 2018

ASE Certifications:

• Medium/Heavy Truck: T2 Diesel Engines (2019, renewed 2024)

• Medium/Heavy Truck: T4 Brakes (2019, renewed 2024)

• Medium/Heavy Truck: T6 Electrical/Electronic Systems (2020)

• Medium/Heavy Truck: T8 Preventive Maintenance (2020)

Additional Certifications:

• Cummins Engine Repair & Maintenance Certification (2022)

• Detroit Diesel Electronic Controls (DDEC) Training (2021)

• OSHA 10-Hour Safety Certification (2019)

TECHNICAL SKILLS

- Engine diagnostics & repair (Cummins, Detroit, CAT)

- Electrical systems troubleshooting

- Air brake systems certification

- Hydraulic system repair

- Transmission overhaul (Eaton Fuller, Allison)

- Exhaust aftertreatment systems (DPF, SCR)

- Welding (MIG, TIG)

- Electronic diagnostic tools (Cummins Insite, Detroit DDDL)

- Preventative maintenance scheduling

- DOT inspection procedures

Computer Skills: Mitchell 1 TruckSeries, Quickbooks, MS Excel, FleetWave Maintenance Software

Senior / Experienced Diesel Mechanic Resume Example

MIKE THOMPSON

Denver, CO • (720) 555-9184 • mikethompson.dieselmech@gmail.com • linkedin.com/in/mike-thompson-diesel

PROFESSIONAL SUMMARY

Seasoned Diesel Mechanic with 10+ years diagnosing, repairing, and maintaining heavy-duty trucks, construction equipment, and diesel engines. Specialize in electrical systems, hydraulics, and computerized diagnostics with a proven track record of reducing fleet downtime by 31%. Skilled trainer who’s mentored 7 apprentice mechanics while maintaining a spotless safety record across multiple high-volume service centers.

EXPERIENCE

Senior Diesel Technician | Rocky Mountain Fleet Services | Denver, CO | 05/2019 – Present

- Lead a team of 5 mechanics servicing a fleet of 87 heavy-duty trucks and construction equipment, reducing overall maintenance costs by $127K annually

- Develop and implement preventative maintenance schedules that decreased emergency repairs by 42% over 3 years

- Diagnose and repair complex electrical issues using advanced diagnostic equipment (Nexiq, Jaltest, Detroit DDDL)

- Rebuilt 14 Cummins ISX engines, extending their service life by an average of 4.5 years

- Maintain detailed service records and parts inventory tracking that improved parts availability by 28%

Diesel Mechanic | Peterson Caterpillar | Colorado Springs, CO | 03/2016 – 04/2019

- Performed repairs and maintenance on Cat equipment including excavators, loaders, and dozers

- Specialized in hydraulic system troubleshooting and repair, resolving complex issues that stumped other techs

- Managed warranty claims and documentation, recovering $76K in parts and labor costs in 2018 alone

- Completed 94% of repair jobs within estimated timeframes (shop average: 82%)

- Mentored 3 apprentice mechanics who all advanced to journeyman positions

Diesel Mechanic | Ryder Truck Rental | Denver, CO | 08/2013 – 02/2016

- Performed preventative maintenance, diagnostics, and repairs on a fleet of 140+ diesel trucks

- Specialized in Detroit Diesel and Cummins engine repairs and maintenance

- Diagnosed and repaired HVAC, electrical, and brake systems on various truck makes/models

- Maintained 97% first-time fix rate on repairs (shop average: 85%)

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Diesel Technology

Denver Automotive & Diesel College – Denver, CO (2013)

Certifications:

- ASE Master Medium/Heavy Truck Technician (T2-T8) – Current

- ASE L2 Electronic Diesel Engine Diagnosis Specialist – Current

- EPA 609 MVAC Certification – Current

- Cummins Virtual College – ISX Engine Certification (2019)

- Detroit Diesel Electronic Controls (DDEC) Certification (2017)

- Cat Certified Hydraulic Technician (2018)

- OSHA 30-Hour Safety Certification (2020)

TECHNICAL SKILLS

- Engine Overhaul & Repair (Cummins, Detroit, CAT, International)

- Advanced Electrical Diagnostics

- Hydraulic Systems Troubleshooting

- Air Brake Systems (ABS)

- Emissions Control Systems (DPF, DEF, EGR)

- Transmission & Driveline Repair

- Welding (MIG, TIG, Stick)

- Heavy Equipment Repair

- Shop Management Software (Mitchell1, AllData)

- Electronic Service Information Systems

ADDITIONAL INFORMATION

Valid CDL Class A with all endorsements

Personal toolbox valued at $40K+

Bilingual: English and Spanish (conversational)

How to Write a Diesel Mechanic Resume

Introduction

Landing a good diesel mechanic job isn't just about your wrench skills—it's about convincing the shop manager you're worth interviewing before they ever see you turn a bolt. Your resume is that first impression. I've reviewed thousands of mechanic resumes over my career, and I can tell you that most get tossed because they fail to showcase the right mix of technical abilities and work habits that shops desperately need. This guide will help you build a resume that gets you in the door, whether you're fresh out of tech school or you've been rebuilding Detroit Diesels since the 90s.

Resume Structure and Format

Keep your resume clean and organized—just like your toolbox should be. Aim for 1-2 pages max, with clear sections and consistent formatting.

- Use a standard, readable font (11-12pt Arial or Calibri works well)

- Include plenty of white space—cramped text is hard to scan

- Break up text with bullet points (4-6 per job is ideal)

- Save as a PDF to maintain formatting (unless asked for a Word doc)

- Name your file professionally: "John_Smith_Diesel_Mechanic.pdf"

If you're applying to larger fleets or dealerships, your resume will likely go through an Applicant Tracking System first. Keep formatting simple and avoid tables, headers/footers, and images that these systems can't process properly.

Profile/Summary Section

Start with a brief (2-4 sentence) summary that highlights your experience level, specializations, and biggest strengths. This isn't the place for your life story—it's your elevator pitch.

Example: "Certified Diesel Mechanic with 7+ years diagnosing and repairing Class 8 trucks and refrigerated trailers. Specialized experience with Cummins ISX engines and Thermo King units. Known for quick, accurate troubleshooting that reduces downtime and keeps fleets moving."

Professional Experience

This is where you prove your worth. Don't just list job duties—show results and specifics:

- Start bullets with action verbs: Diagnosed, Rebuilt, Maintained, Repaired

- Include specific equipment: "Performed complete overhauls on DD15 engines"

- Mention fleet sizes: "Maintained preventive maintenance schedule for 43-truck fleet"

- Add metrics where possible: "Reduced diagnostic time by 17% by implementing systematic troubleshooting procedures"

- Note any specialized systems: "Expert in Bendix air brake systems and Wabco ABS"

Education and Certifications

This industry values credentials. List relevant training chronologically, starting with most recent:

- Technical/vocational training with program name and graduation date

- ASE certifications (especially Medium/Heavy Truck series)

- Manufacturer-specific training (Cummins, Detroit, Volvo, etc.)

- CDL license and endorsements (if applicable)

- OSHA or safety certifications

Keywords and ATS Tips

Many companies use software to filter applications. Include these terms (where honest):

- Diagnostic tools: "Proficient with ESA Electronic Service Analyzer and JPRO"

- Systems: "Experienced troubleshooting EGR systems, DPF regen issues"

- Compliance: "Familiar with DOT inspection requirements and documentation"

- Software: "Skilled with Mitchell 1 TruckSeries, Freightliner ServiceLink"

Industry-specific Terms

Show you speak the language by naturally incorporating terminology like:

- Component names: injectors, turbochargers, ECMs, SCR systems

- Processes: valve adjustments, cylinder head rebuilds, inframe overhauls

- Measuring tools: micrometers, dial indicators, pressure gauges

- Fault codes: "Experienced diagnosing SPN 1569 FMI 31 conditions"

Common Mistakes to Avoid

- Listing every task without focusing on accomplishments

- Being vague ("worked on trucks" vs. "performed electrical diagnostics on Peterbilt 579 models")

- Ignoring preventive maintenance experience—shops value this!

- Omitting relevant side work (like farm equipment repair or personal projects)

- Forgetting to mention your own tools (if you have them)

Before/After Example

Before: "Changed oil and performed maintenance on trucks."

After: "Completed 15-20 PMs weekly on Freightliner Cascadias, performing full 25-point inspections that caught failing wheel seals and air leaks before road failures occurred, saving Fleet Co. approximately $8,300 in towing costs over six months."

Remember—your resume needs to show not just what you can fix, but how your skills translate to value for the employer. Good mechanics are in demand, but great mechanics who can document their skills effectively get the best opportunities!

Related Resume Examples

Soft skills for your Diesel Mechanic resume

- Clear technical communication with both mechanics and non-technical staff

- Patience during complex troubleshooting (especially with intermittent issues)

- Team coordination during rush repairs or fleet maintenance schedules

- Adaptability to changing manufacturer specifications and new diagnostic technologies

- Stress management when handling time-sensitive repairs for stranded drivers

- Mentoring ability for apprentices and entry-level mechanics

Hard skills for your Diesel Mechanic resume

- Diesel Engine Diagnostics and Troubleshooting (Cummins, Detroit, Paccar platforms)

- Electronic Control Module (ECM) programming using OEM software

- Hydraulic system overhaul and repair on heavy equipment

- ASE Certified Medium/Heavy Truck Technician (T2, T3, T4, T8)

- Exhaust after-treatment systems maintenance (DPF, DEF, SCR)

- Air brake system certification and DOT inspection experience

- HVAC recovery and recharge procedures (EPA 609 Certified)

- Blueprint reading and technical manual interpretation

- Mitchell1 TruckSeries and Noregon JPRO diagnostics proficiency