CNC Machinist Resume examples & templates

Copyable CNC Machinist Resume examples

What happens when precision meets artistry in the manufacturing world? CNC Machinists know the answer—they're the skilled professionals who transform digital blueprints into physical reality with tolerances sometimes as tight as ±0.0001 inches. It's a craft that blends technical expertise with problem-solving creativity. Most folks don't realize that behind practically every product we use—from smartphone components to aerospace parts—there's a machinist who helped bring it to life.

The field is evolving rapidly, with 5-axis machines and multi-tasking capabilities becoming standard in progressive shops. According to the Bureau of Labor Statistics, CNC Machinists earn a median annual wage of $47,940, though specialists with advanced programming skills often command salaries exceeding $65,000. And contrary to what you might've heard about manufacturing jobs disappearing, the integration of technologies like machine learning and IoT sensors is actually creating new opportunities for machinists willing to adapt. As manufacturing continues its digital transformation, tomorrow's CNC professionals will be as comfortable with code as they are with calipers.

Junior CNC Machinist Resume Example

Adrian Kovacs

Louisville, KY | (502) 555-7294 | akovacs92@email.com | linkedin.com/in/adriankovacs

Detail-oriented CNC Machinist with hands-on experience operating and maintaining CNC mills and lathes; Skilled in reading blueprints, performing basic G-code programming and ensuring quality control through precise measurements. Quick learner with a mechanical aptitude and proven track record of reducing waste by 17% in current role.

EXPERIENCE

CNC Machinist – Mid-South Manufacturing, Louisville, KY

March 2022 – Present

- Operate 3-axis CNC mills and lathes to produce components for aerospace clients with tolerances of ±0.002″

- Set up machines including workholding devices, tooling and offsets for production runs of 50-300 parts

- Perform in-process quality checks using micrometers, calipers and CMM to verify dimensions match specifications

- Cut machine changeover time from 47 to 32 minutes through improved preparation and organization

- Reduced material waste by 17% through careful planning and program optimization

CNC Operator Trainee – Mid-South Manufacturing, Louisville, KY

September 2021 – March 2022

- Assisted senior machinists with setup and operation of CNC equipment

- Learned basic G-code programming and made simple program adjustments under supervision

- Performed tool changes and basic preventative maintenance on machines

- Handled material prep and deburring operations for machined parts

Production Assistant – Bluegrass Metal Works, Frankfort, KY

May 2021 – August 2021

- Supported manufacturing operations through material handling and inventory management

- Gained initial exposure to machining operations and blueprint reading

- Maintained clean and organized workspaces to ensure safety and efficiency

EDUCATION

Certificate in CNC Machining

Jefferson Community & Technical College, Louisville, KY

Graduated: August 2021

High School Diploma

Eastern High School, Louisville, KY

Graduated: May 2020

CERTIFICATIONS

- NIMS Credential – CNC Milling: Operations (2021)

- OSHA 10-Hour General Industry Safety (2021)

SKILLS

- CNC Mill & Lathe Operation

- Blueprint Reading

- G-code Programming (basic)

- Mastercam (beginner)

- Precision Measurement Tools

- Deburring & Finishing

- Tool Selection & Setup

- Preventative Maintenance

- Quality Control & Inspection

- Microsoft Excel & Word

ADDITIONAL INFORMATION

Workshop Projects: Built custom motorcycle parts using manual and CNC equipment

Availability: Open to overtime and weekend shifts as needed

Mid-level CNC Machinist Resume Example

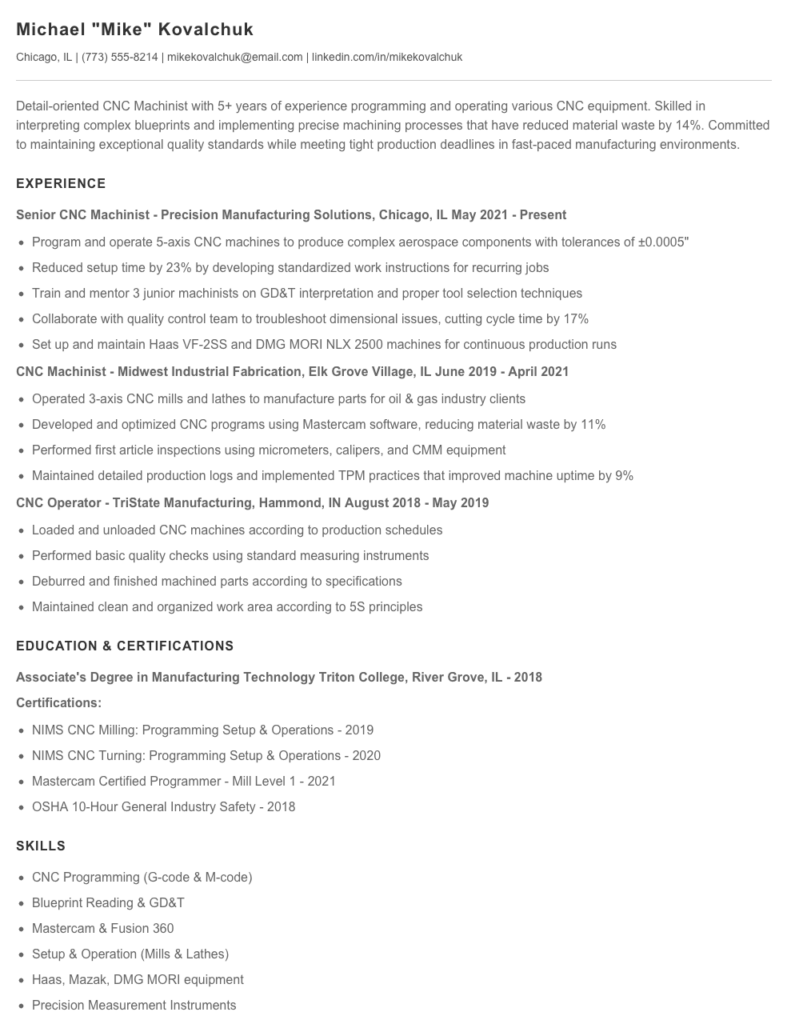

Michael “Mike” Kovalchuk

Chicago, IL | (773) 555-8214 | mikekovalchuk@email.com | linkedin.com/in/mikekovalchuk

Detail-oriented CNC Machinist with 5+ years of experience programming and operating various CNC equipment. Skilled in interpreting complex blueprints and implementing precise machining processes that have reduced material waste by 14%. Committed to maintaining exceptional quality standards while meeting tight production deadlines in fast-paced manufacturing environments.

EXPERIENCE

Senior CNC Machinist – Precision Manufacturing Solutions, Chicago, IL

May 2021 – Present

- Program and operate 5-axis CNC machines to produce complex aerospace components with tolerances of ±0.0005″

- Reduced setup time by 23% by developing standardized work instructions for recurring jobs

- Train and mentor 3 junior machinists on GD&T interpretation and proper tool selection techniques

- Collaborate with quality control team to troubleshoot dimensional issues, cutting cycle time by 17%

- Set up and maintain Haas VF-2SS and DMG MORI NLX 2500 machines for continuous production runs

CNC Machinist – Midwest Industrial Fabrication, Elk Grove Village, IL

June 2019 – April 2021

- Operated 3-axis CNC mills and lathes to manufacture parts for oil & gas industry clients

- Developed and optimized CNC programs using Mastercam software, reducing material waste by 11%

- Performed first article inspections using micrometers, calipers, and CMM equipment

- Maintained detailed production logs and implemented TPM practices that improved machine uptime by 9%

CNC Operator – TriState Manufacturing, Hammond, IN

August 2018 – May 2019

- Loaded and unloaded CNC machines according to production schedules

- Performed basic quality checks using standard measuring instruments

- Deburred and finished machined parts according to specifications

- Maintained clean and organized work area according to 5S principles

EDUCATION & CERTIFICATIONS

Associate’s Degree in Manufacturing Technology

Triton College, River Grove, IL – 2018

Certifications:

- NIMS CNC Milling: Programming Setup & Operations – 2019

- NIMS CNC Turning: Programming Setup & Operations – 2020

- Mastercam Certified Programmer – Mill Level 1 – 2021

- OSHA 10-Hour General Industry Safety – 2018

SKILLS

- CNC Programming (G-code & M-code)

- Blueprint Reading & GD&T

- Mastercam & Fusion 360

- Setup & Operation (Mills & Lathes)

- Haas, Mazak, DMG MORI equipment

- Precision Measurement Instruments

- Troubleshooting & Problem-solving

- Preventative Maintenance

- Tool Selection & Management

- Quality Control Procedures

ADDITIONAL INFORMATION

Weekend volunteer at Chicago Youth Manufacturing Program teaching basic machining skills to high school students. Fluent in English and conversational Ukrainian. Valid forklift certification.

Senior / Experienced CNC Machinist Resume Example

Marcus D. Wilson

Chicago, IL 60613 • (773) 555-8172 • m.wilson.cnc@email.com • linkedin.com/in/marcuswilson-cnc

Precision-focused CNC Machinist with 9+ years programming and operating multi-axis CNC equipment. Specialized in complex part production for aerospace and medical device manufacturing with proven troubleshooting abilities that reduced scrap rates by 17%. Consistently maintain tolerances within ±0.0005″ while exceeding production targets. Currently training junior machinists on advanced G-code programming techniques.

EXPERIENCE

Senior CNC Machinist – Precision Aerospace Components, Chicago, IL (June 2019 – Present)

- Program and operate 5-axis Haas and DMG Mori machines to manufacture critical aerospace components with tolerances as tight as ±0.0003″

- Reduced setup time by 23% by developing standardized fixturing methods for recurring part families

- Implemented tool life management system that decreased tool breakage by 31% and saved approximately $42,800 annually

- Lead a team of 4 machinists during night shift operations, maintaining 99.2% on-time delivery

- Created detailed documentation for 47 complex parts, including step-by-step setup instructions and troubleshooting guides

CNC Machinist II – MedTech Precision, Evanston, IL (April 2016 – May 2019)

- Operated 3 and 4-axis CNC mills and lathes to produce titanium and stainless steel medical implant components

- Programmed complex contours using Mastercam, reducing programming time by 15% compared to manual G-code writing

- Maintained detailed inspection logs and first article documentation for FDA-regulated medical device components

- Collaborated with quality department to implement in-process inspection procedures that decreased final rejection rate from 3.8% to 1.2%

CNC Machinist / Setup Technician – Wilson Manufacturing, Rockford, IL (August 2014 – March 2016)

- Operated CNC lathes and mills to produce hydraulic fittings and valve components

- Performed setups for production runs of 50-5000 pieces, maintaining dimensional accuracy throughout long production cycles

- Assisted in training 3 machine operators on basic CNC operation and inspection techniques

- Identified and corrected a recurring alignment issue that had caused 2.4% scrap rate

EDUCATION & CERTIFICATIONS

Associate of Applied Science, Manufacturing Technology

Harper College, Palatine, IL (2014)

Certifications:

- NIMS Certification – CNC Milling: Programming Setup & Operations (2015)

- NIMS Certification – CNC Turning: Programming Setup & Operations (2015)

- Mastercam Certified Programmer – Mill Level 3 (2018)

- Haas CNC Certification Program (2017)

TECHNICAL SKILLS

- CNC Programming: G-Code, Mastercam, Fusion 360, Fanuc Controls

- Machine Operation: 5-axis machining, Swiss-type lathes, EDM

- Inspection Tools: CMM programming, micrometers, calipers, height gauges, optical comparators

- Materials: Experience with titanium, Inconel, stainless steel, aluminum, plastics

- GD&T interpretation and application (ASME Y14.5)

- SPC and quality control documentation

- Preventive maintenance and troubleshooting

- Blueprint reading and technical drawing interpretation

- CAD software: SolidWorks (basic proficiency)

ADDITIONAL INFORMATION

Shop lead for annual manufacturing day demonstrations for local high school students (2019-2022)

Volunteer instructor at Chicago Makerspace teaching intro to CNC basics (weekends)

How to Write a CNC Machinist Resume

Introduction

Getting noticed in today's manufacturing job market takes more than just skills—you need a resume that showcases your precision on paper as clearly as you demonstrate it on the shop floor. I've helped hundreds of machinists land interviews, and I can tell you this: hiring managers typically spend just 7.4 seconds scanning a resume before deciding whether to continue reading or move on. For CNC machinists, your resume needs to highlight technical expertise while demonstrating attention to detail (a trait you use every day when working to tolerances of 0.0001").

Resume Structure and Format

Keep your resume clean and organized—just like your workstation should be. A cluttered resume suggests a disorganized machinist, which no shop supervisor wants to hire.

- Stick to 1-2 pages (1 page for under 5 years experience, 2 pages for veterans)

- Use standard fonts like Calibri, Arial, or Times New Roman at 10-12pt size

- Include clear section headings with plenty of white space

- Save as both .docx and PDF formats (some application systems prefer one over the other)

- Name your file professionally: "John_Smith_CNC_Machinist_Resume.pdf"

Profile/Summary Section

Your summary should be short but impactful—like a perfectly programmed tool path. This 3-4 line section sits at the top and gives hiring managers a quick overview of your experience, specialization, and key strengths.

Avoid generic statements like "Hardworking machinist seeking new opportunities." Instead, try something specific: "5-axis CNC programmer with 6+ years operating Haas and Mazak systems, specializing in complex aerospace components with tolerances to ±0.0005"."

Professional Experience

This is where the chips hit the floor! Focus on achievements, not just duties. Anyone can list "operated CNC machine"—but not everyone reduced scrap rates by 17% or programmed a process that cut cycle time by 3.5 minutes.

- Start with your most recent position and work backward

- Include company name, location, your title, and dates (month/year)

- For each role, include 4-6 bullet points highlighting accomplishments

- Quantify results whenever possible (parts per hour, tolerance achievements, etc.)

- Mention specific machines, controllers, and software you've mastered

Education and Certifications

List relevant education, whether it's a technical degree, apprenticeship, or on-the-job training. The manufacturing world values skills over degrees, but formal education still matters.

- Technical school diplomas or degrees (with graduation dates)

- Apprenticeship programs or specialized training

- Industry certifications (NIMS, GD&T, etc.)

- CAD/CAM software training (Mastercam, SolidWorks, etc.)

- Skip high school if you have more advanced education

Keywords and ATS Tips

Most companies use Applicant Tracking Systems to screen resumes before human eyes see them. These systems look for specific keywords relevant to CNC machining. Study the job posting carefully and mirror key terms (without keyword stuffing).

Common ATS-friendly keywords for CNC machinists include:

CNC programming, G-code, M-code, CAD/CAM, Mastercam, SolidWorks, GD&T, quality inspection, micrometer, caliper, CMM, preventive maintenance, setup, troubleshooting, 3-axis, 5-axis

Industry-specific Terminology

Show you speak the language of machining by naturally incorporating industry terms. This signals to hiring managers that you understand the field.

- Machine types: mills, lathes, EDM, grinding

- Controller types: Fanuc, Siemens, Heidenhain

- Materials: various metals, plastics, composites you've worked with

- Processes: turning, milling, drilling, boring, threading, tapping

- Measurement: metrology equipment, inspection techniques

Common Mistakes to Avoid

- Typos and grammatical errors (if you can't be precise on paper, how will you be precise with parts?)

- Focusing only on duties rather than accomplishments

- Being vague about machine types and software experience

- Omitting relevant technical skills or certifications

- Using the same generic resume for every application

Before/After Example

BEFORE: "Responsible for operating CNC machines and making parts according to blueprints."

AFTER: "Programmed and operated Haas VF-2 vertical machining center to produce titanium aerospace components with tolerances of ±0.0005", reducing scrap rate from 4.2% to 1.7% within 6 months."

Your resume is like a machined part—it needs to be precise, well-crafted, and meet exact specifications. Take the time to measure twice and cut once when creating this critical document, and you'll be well on your way to landing your next CNC position.

Related Resume Examples

Soft skills for your CNC Machinist resume

- Troubleshooting communication – explaining complex machining issues to supervisors who might not have hands-on experience

- Shop floor collaboration – working effectively alongside welders, quality control techs, and maintenance staff during tight production schedules

- Mentoring junior machinists on setup procedures without micromanaging their work

- Adapting to unexpected material shortages by suggesting alternative approaches

- Time management during multi-part production runs (juggling 4-5 different jobs while maintaining quality standards)

- Stress resilience during breakdown situations and urgent customer orders

Hard skills for your CNC Machinist resume

- CAD/CAM Programming (Mastercam, Fusion 360, ESPRIT)

- G-Code & M-Code Programming

- CNC Lathe & Mill Operation (Haas, Mazak, DMG Mori)

- 3-Axis and 5-Axis Machining

- GD&T Interpretation (ASME Y14.5)

- CMM Operation & Quality Inspection

- Fixture Design & Setup

- Tool Selection & Management

- SPC & First Article Inspection