CMM Programmer Resume examples & templates

Copyable CMM Programmer Resume examples

Precision is everything in manufacturing, but CMM Programmers know the frustrating reality: you're often caught between engineering specs that look perfect on paper and the physical limitations of measurement technology. One tiny programming error or probe path miscalculation can invalidate hours of metrology work—something 72% of quality departments experienced at least quarterly according to a 2023 Manufacturing Quality Report. The push toward higher tolerances hasn't made things easier. Parts that once had ±0.005" tolerances now routinely require ±0.0005" verification, while the equipment you're expected to program hasn't necessarily kept pace.

The field is shifting, though. The integration of CAD-based programming and offline simulation has started reducing setup time by nearly 40% in forward-thinking shops. And with more manufacturers adopting GD&T standards across their documentation, CMM Programmers who can bridge the gap between design intent and measurement execution are becoming invaluable team members. As manufacturing continues its march toward lights-out production and digital twins, your expertise in translating complex geometries into reliable measurement routines will only become more critical to production success.

Junior CMM Programmer Resume Example

Daniel Rivera

Chicago, IL 60615 • (773) 555-0138 • daniel.rivera@email.com • linkedin.com/in/danielrivera

Detail-oriented CMM Programmer with 1+ year experience in precision measurement and quality control. Proficient in PC-DMIS software and experienced with mechanical inspection tools. Engineering technology background with strong analytical skills. Looking to grow into a more autonomous role where I can apply my emerging programming skills.

EXPERIENCE

Junior CMM Programmer • Precision Manufacturing Solutions • Chicago, IL • January 2023 – Present

- Program and operate Brown & Sharpe CMM using PC-DMIS to verify dimensional and geometric tolerances on machined components for medical device industry

- Reduced measurement cycle times by 17% through optimization of probe paths and program refinement

- Create inspection reports and maintain documentation for ISO 13485 compliance

- Assist with measurement system analysis (MSA) and gage R&R studies

- Collaborate with quality engineers to troubleshoot inspection issues and implement solutions

Quality Control Intern • Midwest Aerospace Components • Aurora, IL • June 2022 – December 2022

- Performed first-piece inspections using various measurement tools including calipers, micrometers, and height gauges

- Received training on CMM operation and basic programming under guidance of senior technicians

- Documented inspection results and maintained quality records for aerospace components

- Participated in weekly quality meetings to review non-conformance reports

Manufacturing Assistant (Part-time) • Campus Machine Shop • University of Illinois • September 2021 – May 2022

- Assisted students and faculty with basic machining operations and proper tool selection

- Maintained inventory of shop supplies and ensured equipment cleanliness

- Learned fundamentals of GD&T and basic inspection techniques

EDUCATION

Associate of Applied Science in Mechanical Engineering Technology

University of Illinois Chicago • Graduated: May 2022

Certification: PC-DMIS Level 1 Programming • Hexagon Manufacturing Intelligence • October 2022

Training: GD&T Fundamentals (ASME Y14.5) • Online Course • March 2022

SKILLS

- CMM Programming (PC-DMIS)

- Blueprint Reading

- GD&T (ASME Y14.5)

- Inspection Report Creation

- Quality Control Documentation

- Mechanical Inspection Tools

- Basic CAD (SolidWorks)

- Microsoft Office Suite

- Problem Solving

- Team Collaboration

PROJECTS

CMM Program Optimization Project • November 2023

- Analyzed existing CMM programs for common aluminum housing components

- Implemented new probing strategy that reduced measurement time by 24% while maintaining accuracy requirements

- Created documentation for standardized programming approach

Mid-level CMM Programmer Resume Example

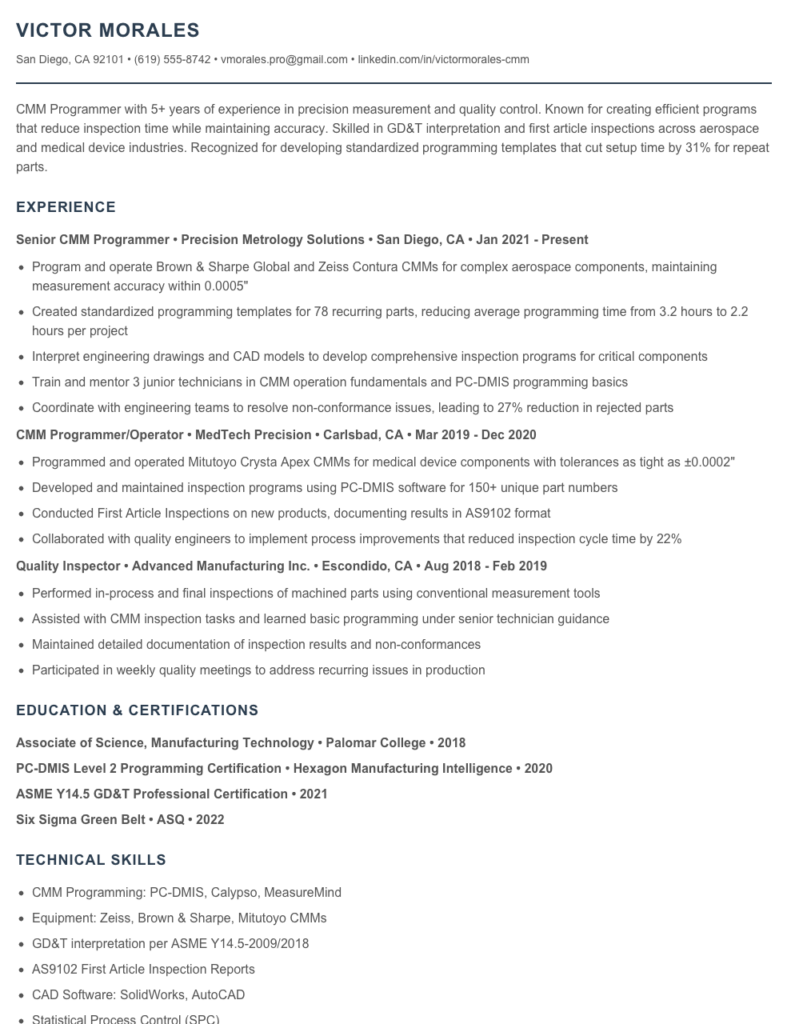

Victor Morales

San Diego, CA 92101 • (619) 555-8742 • vmorales.pro@gmail.com • linkedin.com/in/victormorales-cmm

CMM Programmer with 5+ years of experience in precision measurement and quality control. Known for creating efficient programs that reduce inspection time while maintaining accuracy. Skilled in GD&T interpretation and first article inspections across aerospace and medical device industries. Recognized for developing standardized programming templates that cut setup time by 31% for repeat parts.

EXPERIENCE

Senior CMM Programmer • Precision Metrology Solutions • San Diego, CA • Jan 2021 – Present

- Program and operate Brown & Sharpe Global and Zeiss Contura CMMs for complex aerospace components, maintaining measurement accuracy within 0.0005″

- Created standardized programming templates for 78 recurring parts, reducing average programming time from 3.2 hours to 2.2 hours per project

- Interpret engineering drawings and CAD models to develop comprehensive inspection programs for critical components

- Train and mentor 3 junior technicians in CMM operation fundamentals and PC-DMIS programming basics

- Coordinate with engineering teams to resolve non-conformance issues, leading to 27% reduction in rejected parts

CMM Programmer/Operator • MedTech Precision • Carlsbad, CA • Mar 2019 – Dec 2020

- Programmed and operated Mitutoyo Crysta Apex CMMs for medical device components with tolerances as tight as ±0.0002″

- Developed and maintained inspection programs using PC-DMIS software for 150+ unique part numbers

- Conducted First Article Inspections on new products, documenting results in AS9102 format

- Collaborated with quality engineers to implement process improvements that reduced inspection cycle time by 22%

Quality Inspector • Advanced Manufacturing Inc. • Escondido, CA • Aug 2018 – Feb 2019

- Performed in-process and final inspections of machined parts using conventional measurement tools

- Assisted with CMM inspection tasks and learned basic programming under senior technician guidance

- Maintained detailed documentation of inspection results and non-conformances

- Participated in weekly quality meetings to address recurring issues in production

EDUCATION & CERTIFICATIONS

Associate of Science, Manufacturing Technology • Palomar College • 2018

PC-DMIS Level 2 Programming Certification • Hexagon Manufacturing Intelligence • 2020

ASME Y14.5 GD&T Professional Certification • 2021

Six Sigma Green Belt • ASQ • 2022

TECHNICAL SKILLS

- CMM Programming: PC-DMIS, Calypso, MeasureMind

- Equipment: Zeiss, Brown & Sharpe, Mitutoyo CMMs

- GD&T interpretation per ASME Y14.5-2009/2018

- AS9102 First Article Inspection Reports

- CAD Software: SolidWorks, AutoCAD

- Statistical Process Control (SPC)

- Quality Management Systems (ISO 9001, AS9100)

- Optical Comparator & Vision Systems

- Microsoft Office Suite (Excel, Word, PowerPoint)

- Root Cause Analysis & Problem Solving

Senior / Experienced CMM Programmer Resume Example

CAMERON RODRIGUEZ

Philadelphia, PA • (215) 555-7849 • crodriguez@email.com • linkedin.com/in/cameronrodriguez

Precision-focused CMM Programmer with over 10 years of experience in aerospace, automotive, and medical device manufacturing. Known for optimizing measurement routines that reduced inspection times by 37% while maintaining accuracy to 0.0001″. Experienced mentor who has trained 14+ technicians on advanced programming techniques and GD&T principles. Seeking a senior role to drive quality improvement initiatives.

PROFESSIONAL EXPERIENCE

SENIOR CMM PROGRAMMER | Precision Aerospace Components | Philadelphia, PA | 2018-Present

- Lead a team of 4 CMM programmers supporting quality inspection for components with tolerances as tight as ±0.0002″ across 3 manufacturing facilities

- Developed and implemented automated batch inspection routines that increased throughput by 28% and reduced programming time from 6 hours to 1.5 hours per part family

- Created comprehensive measurement templates for 200+ critical aerospace components, reducing programming errors by 94%

- Integrated CMM operations with SAP quality management system, decreasing report generation time from 45 minutes to 8 minutes per batch

- Collaborated with engineering to resolve complex measurement challenges for titanium turbine blades, resulting in $187K annual savings from reduced scrap

CMM PROGRAMMER/ANALYST | MedTech Precision | Camden, NJ | 2014-2018

- Programmed PC-DMIS routines for FDA-regulated Class II and III medical devices with complex geometries

- Reduced first article inspection time by 32% through custom macro development and fixture standardization

- Authored detailed CMM work instructions and trained 7 technicians on proper measurement techniques

- Managed calibration schedule for 3 Brown & Sharpe CMMs, ensuring NIST traceability and 99.7% equipment uptime

- Led implementation of statistical process control (SPC) for critical features, helping identify and eliminate process variations worth $92K annually

QUALITY TECHNICIAN | Autotek Manufacturing | Allentown, PA | 2011-2014

- Performed dimensional inspections using CMMs, optical comparators, and hand tools

- Assisted with programming routine measurement paths for automotive components

- Documented inspection results and generated quality reports for production teams

- Maintained measurement fixtures and calibration standards per ISO 17025 requirements

EDUCATION & CERTIFICATIONS

Bachelor of Science in Manufacturing Engineering Technology

Penn State University, University Park, PA (2011)

Certifications:

- PC-DMIS Levels 1-3 Programming Certification (2021)

- ASME Y14.5 Geometric Dimensioning & Tolerancing Professional (2019)

- Certified Quality Technician (CQT) – ASQ (2015)

- Zeiss Calypso Advanced Programming (2017)

TECHNICAL SKILLS

- CMM Software: PC-DMIS, Calypso, MCOSMOS, CMM Manager

- CAD Systems: SolidWorks, AutoCAD, CATIA (basic)

- GD&T Application & Analysis (ASME Y14.5-2018)

- Statistical Process Control & Measurement System Analysis

- Fixture Design for Complex Components

- Touch Probe & Laser Scanner Programming

- Reverse Engineering Techniques

- Quality Management Systems (ISO 9001, AS9100)

- Tool Path Optimization & Collision Avoidance

ADDITIONAL INFORMATION

Equipment Experience: Brown & Sharpe, Zeiss, Hexagon, Mitutoyo, Romer Arms

Professional Membership: American Society for Quality (ASQ)

Language: English (Native), Spanish (Conversational)

How to Write a CMM Programmer Resume

Introduction

Landing a job as a CMM Programmer requires more than just technical skills—you need a resume that showcases your precision and expertise. As someone who's reviewed hundreds of metrology resumes, I can tell you that employers spend about 7.4 seconds scanning your resume before deciding whether to continue reading. That's barely enough time to locate the start button on a CMM machine! Your resume needs to highlight your programming abilities, measurement expertise, and attention to detail from the get-go.

Resume Structure and Format

Keep your CMM Programmer resume clean and structured—just like a well-organized measurement program. Stick to 1-2 pages max (unless you have 15+ years of experience), with clear sections and consistent formatting.

- Use reverse chronological format to highlight recent relevant experience

- Choose readable fonts like Calibri or Arial in 10-12pt size

- Include plenty of white space (margins of 0.5-1 inch)

- Save as both .docx and PDF formats (some companies prefer one over the other)

- Name your file professionally: "FirstName_LastName_CMM_Resume.pdf"

Profile/Summary Section

Your summary should be like a first-article inspection—thorough but concise. In 3-4 sentences, highlight your years of experience, specialized skills, and notable achievements. This is where you convince the hiring manager you're worth a deeper look.

Skip the generic "dedicated professional seeking opportunity" opener. Instead, try something like: "CMM Programmer with 6+ years specializing in PC-DMIS and CALYPSO software. Experienced in automotive component measurement with expertise in GD&T and capability studies. Reduced programming time by 31% at Johnson Manufacturing through macro development and process optimization."

Professional Experience

This section is the coordinate system of your resume—everything else aligns to it. For each position, include:

- Company name, location, and employment dates

- Your title and core responsibilities (brief!)

- 4-6 bullet points highlighting specific achievements

- Metrics whenever possible (time saved, accuracy improved, etc.)

Start each bullet with action verbs like "Programmed," "Developed," "Implemented," or "Calibrated." For example: "Programmed complex measurement routines for transmission housing components, reducing inspection time from 8.5 to 5.2 minutes while maintaining 0.001mm accuracy."

Education and Certifications

In metrology, credentials matter. List relevant education with dates, institution names, and locations. CMM Programmers should highlight:

- Formal education (degree in Mechanical Engineering, Manufacturing Technology, etc.)

- Software-specific training (PC-DMIS, CALYPSO, PolyWorks, etc.)

- GD&T certifications (ASME Y14.5)

- Equipment-specific training (Zeiss, Hexagon, Mitutoyo, etc.)

- Quality certifications (ASQ, Six Sigma, etc.)

Keywords and ATS Tips

Most companies use Applicant Tracking Systems that scan resumes before human eyes see them. To pass this first inspection:

- Include specific CMM equipment you've used (Zeiss CONTURA, Brown & Sharpe Global, etc.)

- Name all software programs you're proficient with

- Mention industry standards you're familiar with (ISO 17025, AS9100)

- Use terminology from the job posting (sometimes they're looking for "operators" vs. "programmers")

Industry-specific Terms

Sprinkling these terms throughout your resume shows you speak the language:

- Coordinate Measuring Machine (CMM)

- GD&T (Geometric Dimensioning and Tolerancing)

- Metrology software (PC-DMIS, CALYPSO, Polyworks, etc.)

- First Article Inspection (FAI)

- PPAP (Production Part Approval Process)

- Alignment procedures

- Fixture design

- SPC (Statistical Process Control)

Common Mistakes to Avoid

- Listing only job duties without measurable achievements

- Being vague about software versions or equipment models

- Forgetting to mention experience with different probe systems

- Overlooking soft skills like troubleshooting or training others

- Using too many acronyms without explaining them at least once

Remember, your resume is like a measurement program—it needs to be accurate, comprehensive, and designed for its specific purpose. Tailor it for each job application, just like you'd optimize a program for different part families. Good luck, and may your career measurements always be within tolerance!

Related Resume Examples

Soft skills for your CMM Programmer resume

- Cross-functional collaboration – ability to work with designers, engineers, and quality control teams to optimize measurement processes

- Technical troubleshooting communication – explaining complex measurement issues to non-technical stakeholders in clear terms

- Attention to detail when interpreting GD&T specifications (caught a 0.02mm tolerance error that saved $47K in production costs)

- Shop floor mentorship of junior operators without creating dependency (teach, don’t do)

- Adaptability to changing production priorities while maintaining measurement accuracy standards

- Time management during tight inspection windows – balancing speed and precision requirements

Hard skills for your CMM Programmer resume

- PC-DMIS measurement software with 6+ years daily programming experience

- GD&T interpretation and application per ASME Y14.5-2009 standards

- CAD data import/manipulation (CATIA, SolidWorks, NX)

- Renishaw probe calibration and configuration

- CMM retrofitting and maintenance troubleshooting

- Automated measurement sequence optimization for cycle time reduction

- Statistical Process Control (SPC) data analysis using Minitab

- Fixturing design and setup for complex aerospace components

- Calypso programming for Zeiss equipment integration