Cabinet Maker Resume examples & templates

Copyable Cabinet Maker Resume examples

What happens when raw lumber meets precise craftsmanship and artistic vision? Cabinet making sits at this exact intersection of functional construction and fine woodworking artistry. It's a profession where millimeter-perfect measurements matter just as much as an eye for grain patterns and finish quality. In recent years, we've seen a fascinating shift in the industry—cabinet makers increasingly blend traditional hand techniques with digital fabrication. CNC technology and parametric design software aren't replacing skilled hands; they're expanding what those hands can create. According to the Woodworking Network's 2023 industry report, shops that integrate digital tools with traditional methods report a 27% increase in project complexity without sacrificing completion timelines.

The modern cabinet maker is part artist, part engineer, and part problem-solver. You might be crafting custom built-ins for a century home one week and producing sleek, minimalist kitchen cabinetry the next. With the surge in home renovations continuing post-pandemic and the renewed appreciation for quality craftsmanship, cabinet making offers a career path where your skills remain in demand while your creative possibilities keep expanding. The future belongs to makers who can bridge traditional craftsmanship with contemporary possibilities.

Junior Cabinet Maker Resume Example

Daniel Martinez

Chicago, IL | (312) 555-2194 | dmartinez.woodwork@email.com | linkedin.com/in/dmartinez-woodwork

Cabinet Maker with 1+ year professional experience and 3+ years of woodworking background. Skilled in custom cabinetry construction, fine finishing techniques, and blueprint interpretation. Dedicated to precision craftsmanship with growing expertise in modern cabinet construction methods and traditional woodworking techniques.

EXPERIENCE

Junior Cabinet Maker – Evergreen Custom Cabinetry, Chicago, IL (July 2022 – Present)

- Construct and install custom cabinetry for residential kitchens and bathrooms, averaging 4-5 cabinet sets per month

- Cut, shape, and assemble cabinet components using table saws, routers, and joinery techniques with 99% accuracy rate

- Apply finishes including stains, paints, and clear coats to match client specifications

- Collaborate with 3 senior cabinet makers to complete large-scale projects for high-end residential clients

- Reduced material waste by 14% through careful planning and precise measurements

Woodworking Apprentice – Mason Brothers Furniture, Evanston, IL (March 2021 – June 2022)

- Assisted in the production of custom furniture pieces and basic cabinetry under master craftsman supervision

- Prepared wood components through milling, sanding, and finishing processes

- Learned fundamental joinery techniques including mortise and tenon, dovetail, and pocket hole construction

- Maintained shop equipment and organized materials inventory

Woodshop Assistant (Part-time) – Lakeside Community College, Evanston, IL (Sept 2019 – Feb 2021)

- Monitored student safety and assisted instructors during woodworking classes

- Maintained equipment functionality and cleanliness in 2,500 sq ft woodshop facility

- Provided basic instruction to beginning woodworking students on tool usage and safety protocols

EDUCATION

Associate of Applied Science – Cabinetmaking & Millwork

Lakeside Community College, Evanston, IL – May 2021

Certificates & Training:

- OSHA 10-Hour Construction Safety & Health (2022)

- Advanced Finishing Techniques Workshop – Chicago Woodworkers Guild (2021)

- Cabinet Vision Software Training – Basic (2022)

SKILLS

- Cabinet Construction & Installation

- Blueprint Reading & Interpretation

- Precision Measurements

- Power Tool Operation (Table Saw, Router, Jointer, Planer)

- Hand Tool Proficiency

- Finishing Applications (Stains, Lacquers, Paints)

- Basic CNC Programming

- Cabinet Hardware Installation

- Shop Safety Procedures

- Material Selection & Estimation

ADDITIONAL INFORMATION

Personal Project: Built home workshop with custom tool storage and workbench (photos available upon request)

Mid-level Cabinet Maker Resume Example

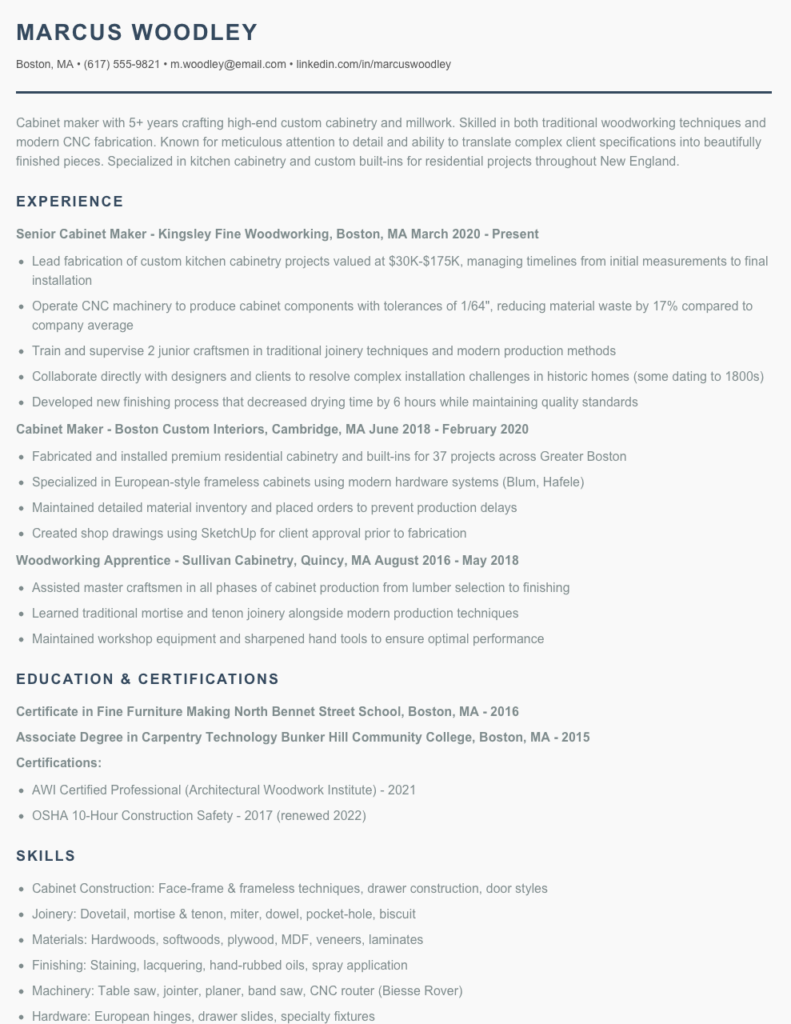

Marcus Woodley

Boston, MA • (617) 555-9821 • m.woodley@email.com • linkedin.com/in/marcuswoodley

Cabinet maker with 5+ years crafting high-end custom cabinetry and millwork. Skilled in both traditional woodworking techniques and modern CNC fabrication. Known for meticulous attention to detail and ability to translate complex client specifications into beautifully finished pieces. Specialized in kitchen cabinetry and custom built-ins for residential projects throughout New England.

EXPERIENCE

Senior Cabinet Maker – Kingsley Fine Woodworking, Boston, MA

March 2020 – Present

- Lead fabrication of custom kitchen cabinetry projects valued at $30K-$175K, managing timelines from initial measurements to final installation

- Operate CNC machinery to produce cabinet components with tolerances of 1/64″, reducing material waste by 17% compared to company average

- Train and supervise 2 junior craftsmen in traditional joinery techniques and modern production methods

- Collaborate directly with designers and clients to resolve complex installation challenges in historic homes (some dating to 1800s)

- Developed new finishing process that decreased drying time by 6 hours while maintaining quality standards

Cabinet Maker – Boston Custom Interiors, Cambridge, MA

June 2018 – February 2020

- Fabricated and installed premium residential cabinetry and built-ins for 37 projects across Greater Boston

- Specialized in European-style frameless cabinets using modern hardware systems (Blum, Hafele)

- Maintained detailed material inventory and placed orders to prevent production delays

- Created shop drawings using SketchUp for client approval prior to fabrication

Woodworking Apprentice – Sullivan Cabinetry, Quincy, MA

August 2016 – May 2018

- Assisted master craftsmen in all phases of cabinet production from lumber selection to finishing

- Learned traditional mortise and tenon joinery alongside modern production techniques

- Maintained workshop equipment and sharpened hand tools to ensure optimal performance

EDUCATION & CERTIFICATIONS

Certificate in Fine Furniture Making

North Bennet Street School, Boston, MA – 2016

Associate Degree in Carpentry Technology

Bunker Hill Community College, Boston, MA – 2015

Certifications:

- AWI Certified Professional (Architectural Woodwork Institute) – 2021

- OSHA 10-Hour Construction Safety – 2017 (renewed 2022)

SKILLS

- Cabinet Construction: Face-frame & frameless techniques, drawer construction, door styles

- Joinery: Dovetail, mortise & tenon, miter, dowel, pocket-hole, biscuit

- Materials: Hardwoods, softwoods, plywood, MDF, veneers, laminates

- Finishing: Staining, lacquering, hand-rubbed oils, spray application

- Machinery: Table saw, jointer, planer, band saw, CNC router (Biesse Rover)

- Hardware: European hinges, drawer slides, specialty fixtures

- Software: SketchUp, AutoCAD (basic), CabinetVision

- Installation: Leveling, scribing, trim carpentry

- Project Management: Material estimation, timeline planning, client coordination

Senior / Experienced Cabinet Maker Resume Example

Michael “Mike” Donovan

Portland, OR 97214 • (503) 555-7821 • mdonovan.cabinets@email.com • linkedin.com/in/mikedonovan-cabinets

PROFESSIONAL SUMMARY

Meticulous Cabinet Maker with 11+ years crafting high-end custom cabinetry and fine furniture. Known for solving complex design challenges while maintaining exceptional craftsmanship. My background includes managing small production teams, training apprentices, and developing relationships with suppliers to secure premium hardwoods at competitive prices. Currently seeking a lead cabinetmaker role where I can apply my expertise in both traditional joinery and modern CNC fabrication.

PROFESSIONAL EXPERIENCE

Lead Cabinet Maker | Evergreen Custom Woodworks | Portland, OR | Jan 2019 – Present

- Manage production of 6-8 complete kitchen cabinet installations monthly, from initial client consultation through final installation

- Supervise a team of 3 junior cabinet makers and 2 apprentices, providing technical training and quality control oversight

- Reduced material waste by 17% by implementing improved cutting diagrams and offcut storage system

- Design and build custom cabinetry for high-end residential projects ranging from $45K-$175K

- Operate CNC machine for precision cutting while maintaining traditional hand-tool skills for specialty pieces

- Developed new finishing technique that reduced drying time by 31% without compromising quality

Cabinet Maker | Portland Fine Furniture | Portland, OR | Mar 2016 – Dec 2018

- Produced custom hardwood cabinets, entertainment centers, and built-ins for residential clients

- Collaborated with 2 designers to translate client visions into functional, beautiful cabinetry

- Specialized in traditional joinery techniques including dovetail, mortise and tenon, and finger joints

- Maintained and calibrated shop equipment, extending the life of 3 major tools by ~4 years

- Created detailed shop drawings and cut lists for 5-7 projects simultaneously

Cabinet Maker Assistant | Jensen’s Cabinet Shop | Eugene, OR | Aug 2013 – Feb 2016

- Assisted master cabinetmakers with material preparation, assembly, finishing, and installation

- Developed proficiency in reading blueprints and translating measurements to finished products

- Managed inventory of hardware, lumber, and shop supplies, reducing stockouts by 23%

- Built jigs and templates to increase production efficiency for repeated components

EDUCATION & CERTIFICATIONS

Fine Woodworking Certificate – Oregon School of Craft, Portland, OR (2012)

Cabinetmaking Apprenticeship – Jensen’s Cabinet Shop, Eugene, OR (2013-2016)

Advanced CNC Programming for Woodworkers – Woodcraft University (2018)

OSHA Safety Certification – Renewed 2022

TECHNICAL SKILLS

- Traditional joinery techniques (dovetail, mortise & tenon, miter, cope & stick)

- CNC programming and operation (Biesse, ShopBot)

- CAD software (Cabinet Vision, SketchUp Pro, AutoCAD)

- Finishing techniques (hand-rubbed oils, lacquers, water-based finishes, spray application)

- Blueprint reading and shop drawing creation

- Material selection and lumber grading

- Precision measuring and layout

- Tool maintenance and calibration

- Hardware installation (European and traditional hinges, drawer slides, specialty mechanisms)

- Veneering and inlay work

SPECIALIZED KNOWLEDGE

- Wood species properties and appropriate applications

- Moisture content management and wood movement compensation

- ADA compliance requirements for cabinetry

- Kitchen & Bath Industry Standards (KBIS)

- Historic restoration techniques (worked on 1890s Victorian home restoration project, 2020)

How to Write a Cabinet Maker Resume

Introduction

Creating a standout cabinet maker resume isn't just about listing where you've worked—it's about showcasing your craftsmanship, attention to detail, and technical expertise. I've reviewed thousands of woodworking resumes over my career, and the difference between those that get interviews and those that don't often comes down to how well they demonstrate specific skills and project experience. Your resume needs to reflect the precision you bring to your cabinetry work!

Resume Structure and Format

Keep your resume clean and organized—just like your workshop. A cluttered resume suggests a cluttered mind (and no shop owner wants that).

- Stick to 1-2 pages max—one page is perfect for those with under 7 years of experience

- Use clear section headings (Experience, Skills, Education) with plenty of white space

- Choose readable fonts like Arial, Calibri, or Garanius at 10-12pt size

- Save as a PDF unless specifically asked for another format

- Name your file professionally: "JohnSmith_CabinetMaker_Resume.pdf"

Profile/Summary Section

Your summary should be short but impactful—like that perfect joint that doesn't need excessive explanation.

- Keep it under 4 lines

- Mention your years of experience, specialization areas, and 1-2 standout accomplishments

- Include your most impressive certification right away

Always tailor your summary to the specific job. For custom cabinetry shops, emphasize design skills and attention to detail. For production environments, highlight efficiency and consistency in your work.

Professional Experience

This is where you build your case (pun intended). Don't just list duties—show what makes your work exceptional.

- Start bullet points with strong action verbs: Crafted, Constructed, Designed, Installed

- Include numbers where possible: "Completed 27 custom kitchen installations averaging $32,000 per project"

- Mention specific materials you've worked with (maple, walnut, MDF, plywood)

- Highlight both hand tool and power tool proficiency

- Note any specialty techniques: dovetail joints, inlay work, veneering

Education and Certifications

Formal training matters in this field, whether it's traditional education or apprenticeships.

- List relevant vocational training, apprenticeships, or degrees

- Include AWI certifications, OSHA safety credentials, or manufacturer certifications

- Mention specific training programs (CNC programming, AutoCAD, specific finishing techniques)

- If you're self-taught, list workshops, significant mentorships, or specialized training you've completed

Keywords and ATS Tips

Many larger shops and contractors use software to filter resumes before a human ever sees them. Beat the system by incorporating these terms naturally throughout your resume:

- Technical terms: face frame, inset doors, overlay, drawer slides, joinery techniques

- Tools: table saw, jointer, planer, router, CNC, Kreg jigs

- Materials: hardwoods, sheet goods, veneers, laminates

- Software: SketchUp, Cabinet Vision, AutoCAD, Microvellum

Industry-specific Terms

Show you speak the language of cabinetry by naturally incorporating terminology like:

- European vs. face frame construction

- 32mm system

- Box construction techniques

- Finishing methods (spray lacquer, hand-rubbed oil)

- Hardware installation (soft-close, push-to-open)

Common Mistakes to Avoid

- Being vague about your skills ("good with tools" vs. "proficient with Festool track saw system")

- Omitting project complexity or scale

- Focusing only on construction without mentioning client interaction or problem-solving

- Forgetting to list measuring accuracy or quality control processes

- Using woodworking jargon without explaining relevance to job performance

Before/After Example

Before: "Responsible for making cabinets at Smith Woodworking."

After: "Crafted custom kitchen cabinetry using maple and cherry hardwoods, completing 6-8 full kitchen projects monthly while maintaining a 99.3% client satisfaction rate and reducing material waste by 17% through optimized cutting layouts."

Remember, your resume should reflect the same level of craftsmanship as your cabinets. Take the time to measure twice and cut once—a little extra effort now can open doors to better opportunities later!

Related Resume Examples

Soft skills for your Cabinet Maker resume

- Active listening during client consultations to translate vague design ideas into tangible furniture plans

- Spatial problem-solving to adapt cabinet designs when encountering unexpected structural features

- Client relationship management – balancing aesthetic preferences with practical limitations

- Time estimation skills for quoting realistic project timelines (even when clients want it yesterday!)

- Workshop mentoring of junior craftspeople without micromanaging their hands-on techniques

- Attention to detail while maintaining awareness of overall project flow

Hard skills for your Cabinet Maker resume

- Proficient in CNC programming and operation (Biesse, SCM, Homag machines)

- Technical blueprint reading and shop drawing interpretation

- Custom veneer application and book-matching techniques

- Cabinetry hardware installation (European slides, soft-close mechanisms)

- CAD experience with Cabinet Vision, SketchUp, and AutoCAD

- Advanced joinery methods including mortise and tenon, dovetail, and mitered joints

- Finishing techniques – spraying catalyzed lacquers and hand-rubbed oils

- Material estimating and cutting list preparation

- Use of traditional hand tools alongside power equipment